PVC (polyvinyl chloride) material for cable shells and preparation method of PVC material

A technology of PVC material and cable casing, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of flame retardant effect and poor thermal insulation effect, trouble of flame retardant performance of wires and cables, a large amount of toxic smoke, etc. problem, to achieve the effect of excellent flexibility, overall performance improvement, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

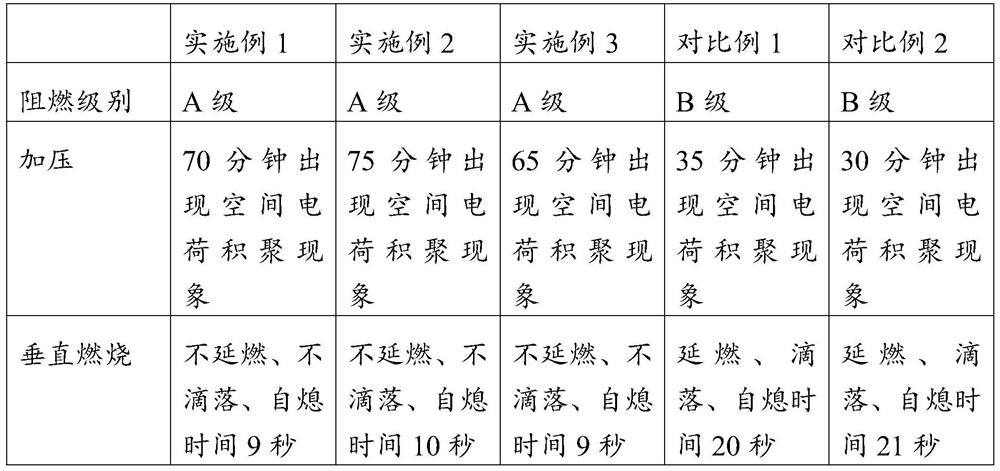

Embodiment 1

[0024] A PVC material for cable shells, comprising the following components in parts by weight: 100 parts of PVC pellets, 0.3 parts of lubricant, 20 parts of modified plasticizer, 0.5 parts of antioxidant, 1 part of flame retardant, 15 parts of filler, 20 parts of foam filler, 10 parts of asbestos particles, and 15 parts of glaze liquid.

[0025] The modified plasticizer is made by fully mixing and stirring polymethyl methacrylate and phosphite antioxidant; the filler includes a mixture of calcium carbonate, ceramic powder, and silicon dioxide at a ratio of 1:1:1, and the ceramic powder and silicon dioxide as micron-level powder; the glaze liquid is made by mixing 10 parts of tourmaline, 5 parts of magnesium gas stone, 2 parts of quartz, 20 parts of kaolin, 3 parts of alumina and 12 parts of lithium porcelain stone, then ball milling, sieving and adding water into a slurry.

[0026] The above preparation method for the PVC material of the cable sheath comprises the following ...

Embodiment 2

[0032] A PVC material used for cable shells, comprising the following components in parts by weight: 150 parts of PVC pellets, 0.6 parts of lubricant, 50 parts of modified plasticizer, 5 parts of antioxidant, 10 parts of flame retardant, 50 parts of filler, 40 parts of foam filler, 20 parts of asbestos particles, and 30 parts of glaze liquid.

[0033] The modified plasticizer is made by fully mixing and stirring polymethyl methacrylate and phosphite antioxidant; the filler includes a mixture of calcium carbonate, ceramic powder, and silicon dioxide at a ratio of 1:1:1, and the ceramic powder and silicon dioxide are micron-level powders; the glaze liquid is made by mixing 15 parts of tourmaline, 20 parts of magnesium gas stone, 8 parts of quartz, 30 parts of kaolin, 10 parts of alumina, and 22 parts of lithium china stone, then ball milling, sieving and adding water into a slurry.

[0034] The above preparation method for the PVC material of the cable sheath comprises the foll...

Embodiment 3

[0040] A PVC material used for cable shells, comprising the following components in parts by weight: 125 parts of PVC pellets, 0.5 parts of lubricant, 30 parts of modified plasticizer, 3 parts of antioxidant, 5 parts of flame retardant, 35 parts of filler, 30 parts of foam filler, 15 parts of asbestos particles, and 20 parts of glaze liquid.

[0041] The modified plasticizer is made by fully mixing and stirring polymethyl methacrylate and phosphite antioxidant; the filler includes a mixture of calcium carbonate, ceramic powder, and silicon dioxide at a ratio of 1:1:1, and the ceramic powder and silicon dioxide are micron-level powders; the glaze liquid is made by mixing 12 parts of tourmaline, 12 parts of magnesium gas stone, 5 parts of quartz, 25 parts of kaolin, 7 parts of alumina and 18 parts of lithium china stone, ball milling, and adding water after sieving into a slurry.

[0042] The above preparation method for the PVC material of the cable sheath comprises the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com