Flame-retardant thermal-insulation hollow brick and manufacturing method thereof

A flame-retardant heat preservation and manufacturing method technology, applied in the direction of heat preservation, building structure, building components, etc., can solve the problems of poor mechanical properties, weak flame retardancy, etc., achieve good performance controllability, enhance flexural strength and anti-corrosion The effect of compressive strength, excellent thermal insulation performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A flame-retardant heat-insulating hollow brick, the composition of the hollow brick is as follows:

[0022] Fly ash floating beads

20 copies

expanded perlite

25 copies

3 copies

5 copies

2 copies

4 parts

expandable graphite

2 copies

Sericite powder

10 copies

1 copy

1 copy

[0023] The manufacture method of this hollow brick comprises the following steps:

[0024] (1) Add sericite powder into the container, add water and ethanol mixture according to the weight ratio of 1:4, then add the silane coupling agent KH570 according to the mass ratio of 10:1, disperse by ultrasonic wave for 0.5h, then add dilute hydrochloric acid Adjust the pH to 3, stir and raise the temperature to 65°C, let stand for 30 minutes, add ethanol to wash three times, an...

Embodiment 2

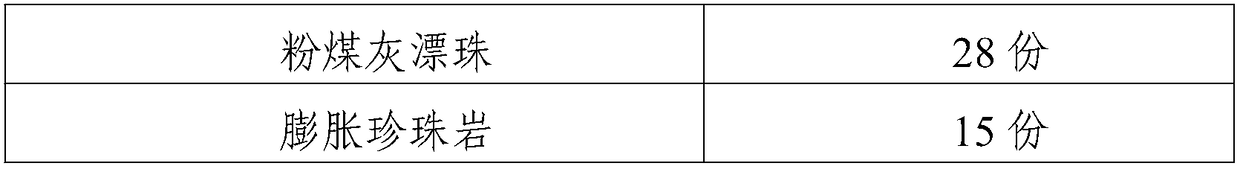

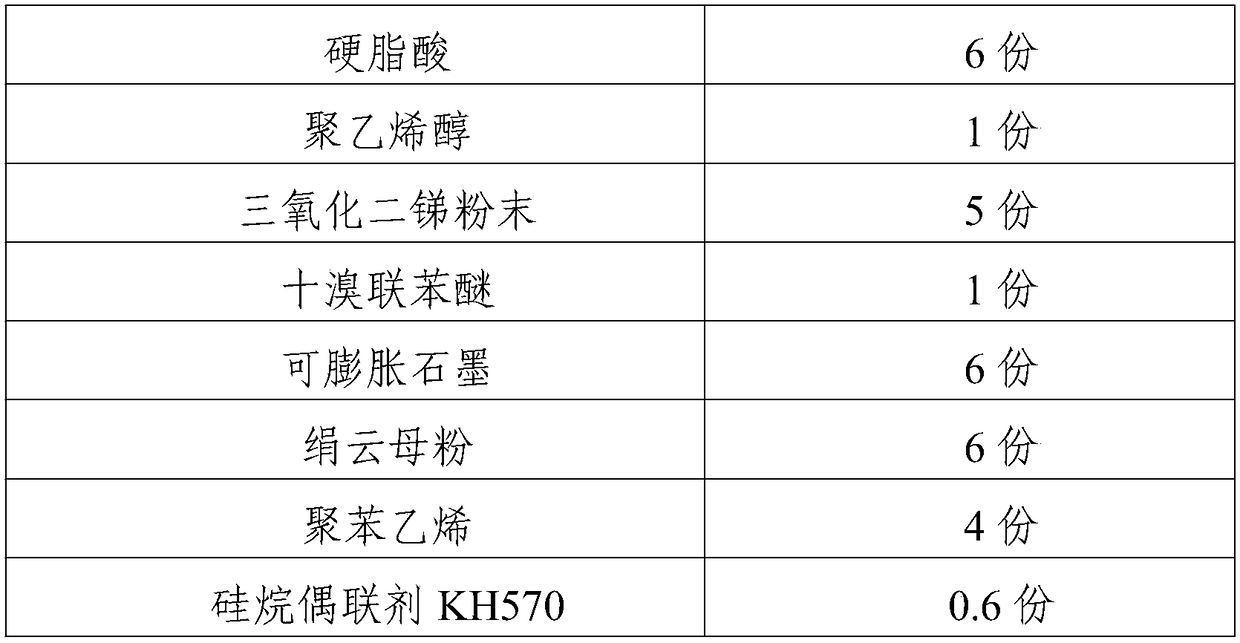

[0029] A flame-retardant and heat-retaining hollow brick, which is composed of the following raw materials in parts by weight:

[0030]

[0031]

[0032] The manufacture method of this hollow brick comprises the following steps:

[0033] (1) Add sericite powder into the container, add water and ethanol mixture according to the weight ratio of 1:4, then add the silane coupling agent KH570 according to the mass ratio of 10:1, disperse by ultrasonic wave for 0.5h, then add dilute hydrochloric acid Adjust the pH to 3, stir and raise the temperature to 65°C, let stand for 30 minutes, add ethanol to wash three times, and then vacuum-dry to constant weight to obtain activated sericite;

[0034] (2) Wrap antimony trioxide powder, expandable graphite and decabromodiphenyl ether on the surface of pre-expanded polystyrene beads by pre-blending method, and form polystyrene composite materials by steam hot pressing;

[0035] (3) Mix fly ash floating beads, expanded perlite, stearic ...

Embodiment 3

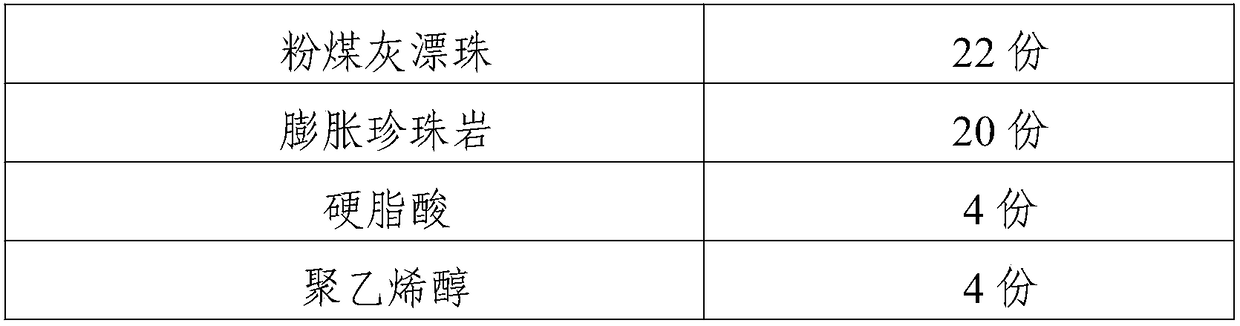

[0038] A flame-retardant and heat-retaining hollow brick, which is composed of the following raw materials in parts by weight:

[0039]

[0040]

[0041] The preparation method of this hollow brick is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com