Electrostatic transducer

An electrostatic, transducer technology used in the loudspeaker field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

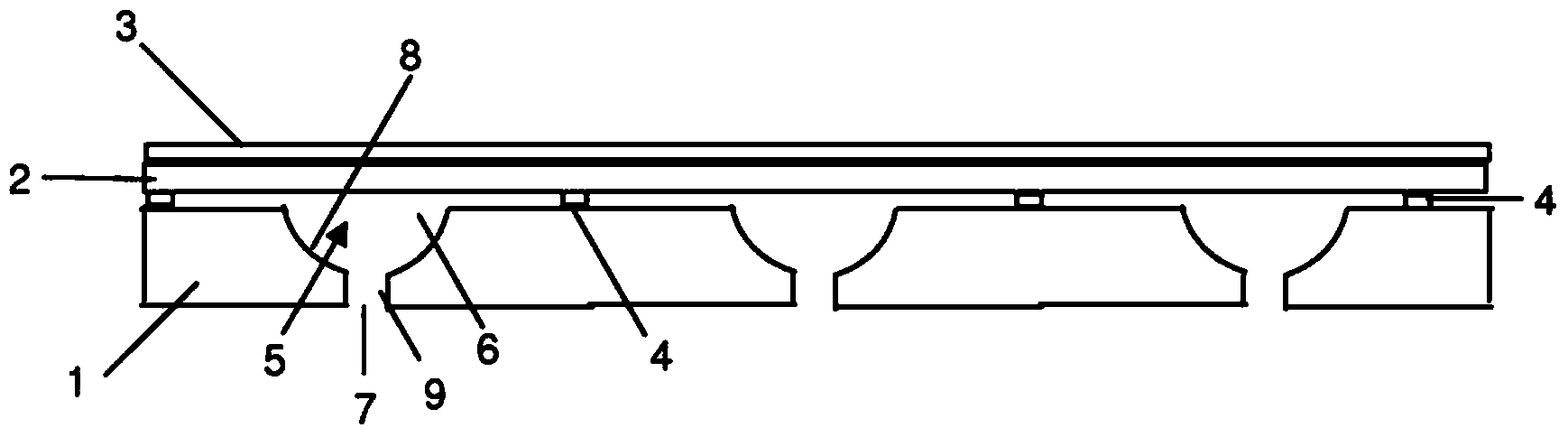

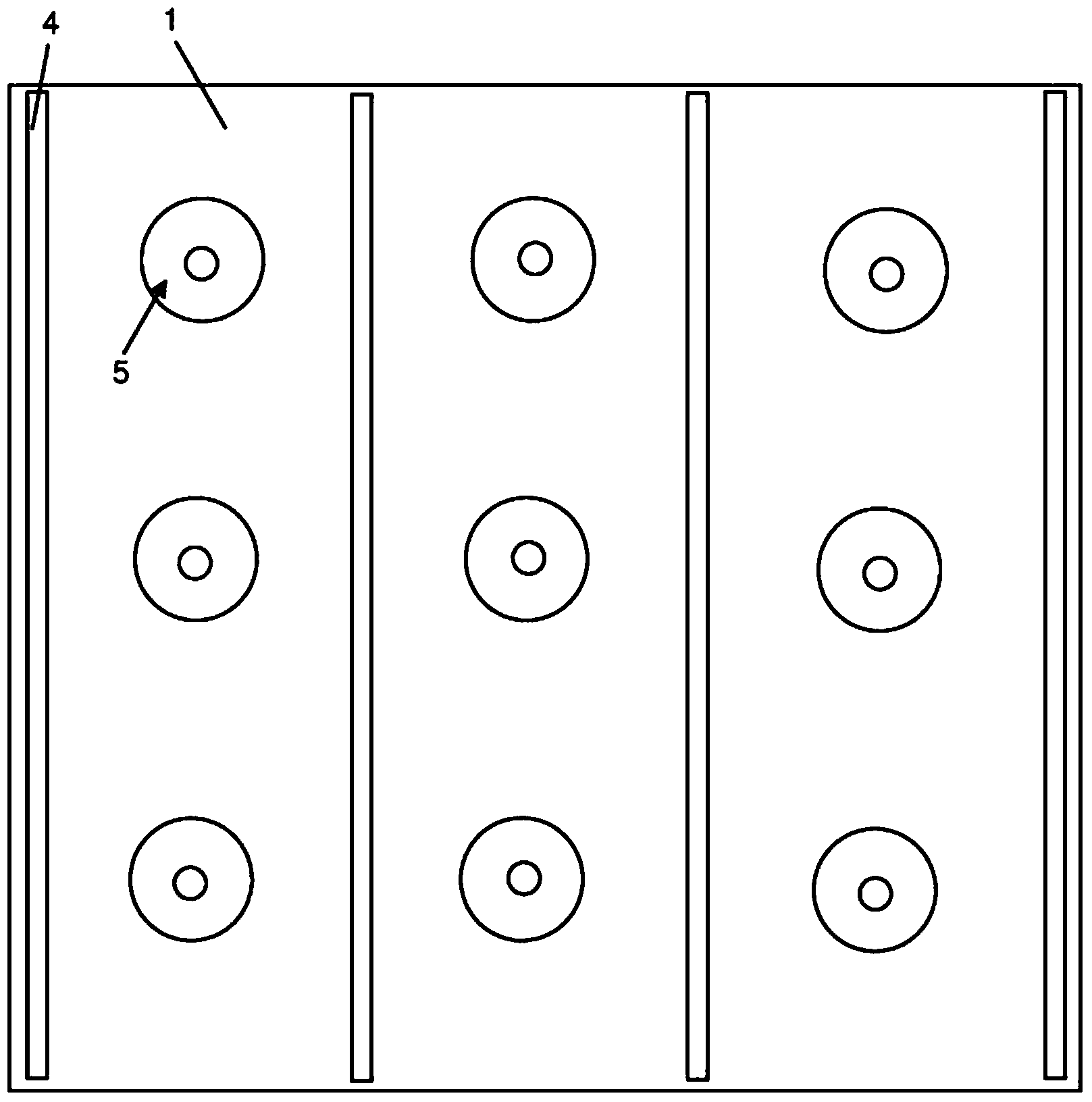

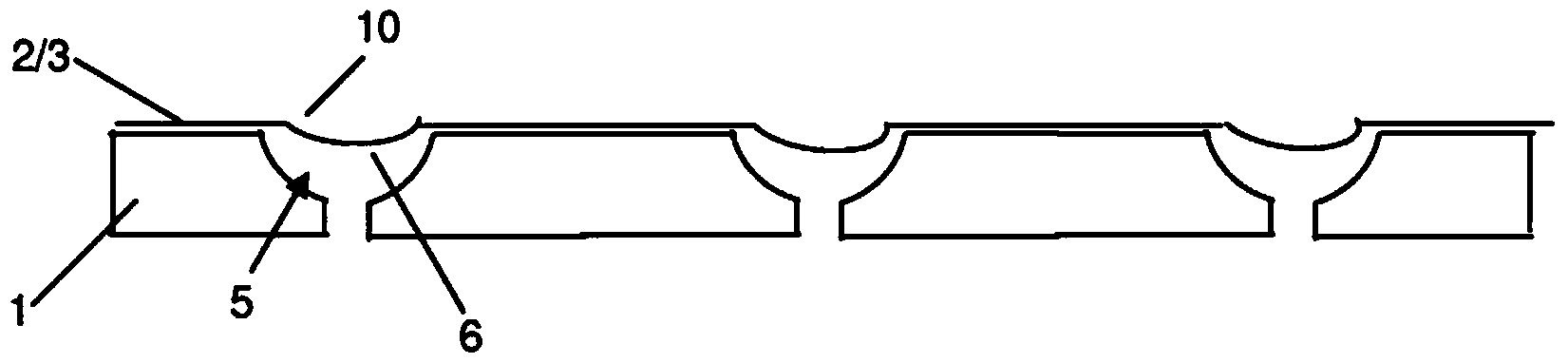

[0059] Such as figure 1 The loudspeaker shown comprises a first layer or backplane 1 having a thickness of approximately 3 mm. This backplane is made of an insulating polymer, on the upper surface of which is provided a conductive layer (not shown). On this conductive layer is a flexible layer 2 of insulating polymer film, on which is a conductive layer 3 . The conductive layer 3 and the insulating layer 2 may be separate layers, but in this embodiment the conductive layer 3 is in the form of metallization on the outer surface of the insulating layer 2 to provide a film with a total thickness of about 12 microns (microns), Although films with a thickness of about 6 microns may be used in some embodiments. Mylar TM The insulating tape 4 is placed between layer 1 and layer 2. The bands are between 1 and 2 mm wide and approximately 20 to 25 microns thick.

[0060] The back plate 1 is provided with rows of through holes 5 . Each aperture 5 has an inlet 6 facing the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com