Precise transverse cutting knife and cutting method for flexible thin-film solar battery

A technology for solar cells and flexible thin films, applied in circuits, electrical components, climate sustainability, etc., can solve problems such as short-circuit efficiency and attenuation of flexible thin-film solar cells, reduce damage and burrs, and achieve high efficiency and complete protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solution and advantages of the present invention clearer, the precision cross-cutting knife and the cutting method of the present invention will be described in detail below with reference to the accompanying drawings and examples.

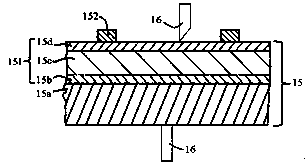

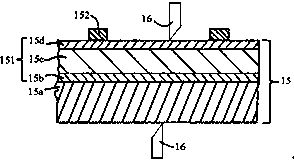

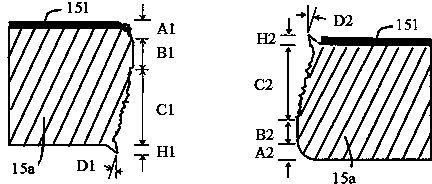

[0040] In this embodiment, cutting a flexible compound thin film solar cell is taken as an example, and the substrate of the compound thin film solar cell is stainless steel foil. figure 1 It is a structural schematic diagram of a compound thin-film solar cell to be cross-cut in the embodiment of the present invention, including a metal substrate 15a, a metal back electrode film layer 15b, a semiconductor material film layer 15c, a TCO material film layer 15d and a gate 152, and a metal back electrode film layer 15b. The electrode film layer 15b, the semiconductor material film layer 15c and the TCO material film layer 15d constitute the functional film layer 151 of the thin film battery.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com