Method of producing MCM-49 molecular sieve

A technology of MCM-49 and molecular sieve, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high cost of molecular sieve, high price of hexamethyleneimine, restricting the wide application of MCM-49 molecular sieve, etc., and shorten the crystallization Time and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

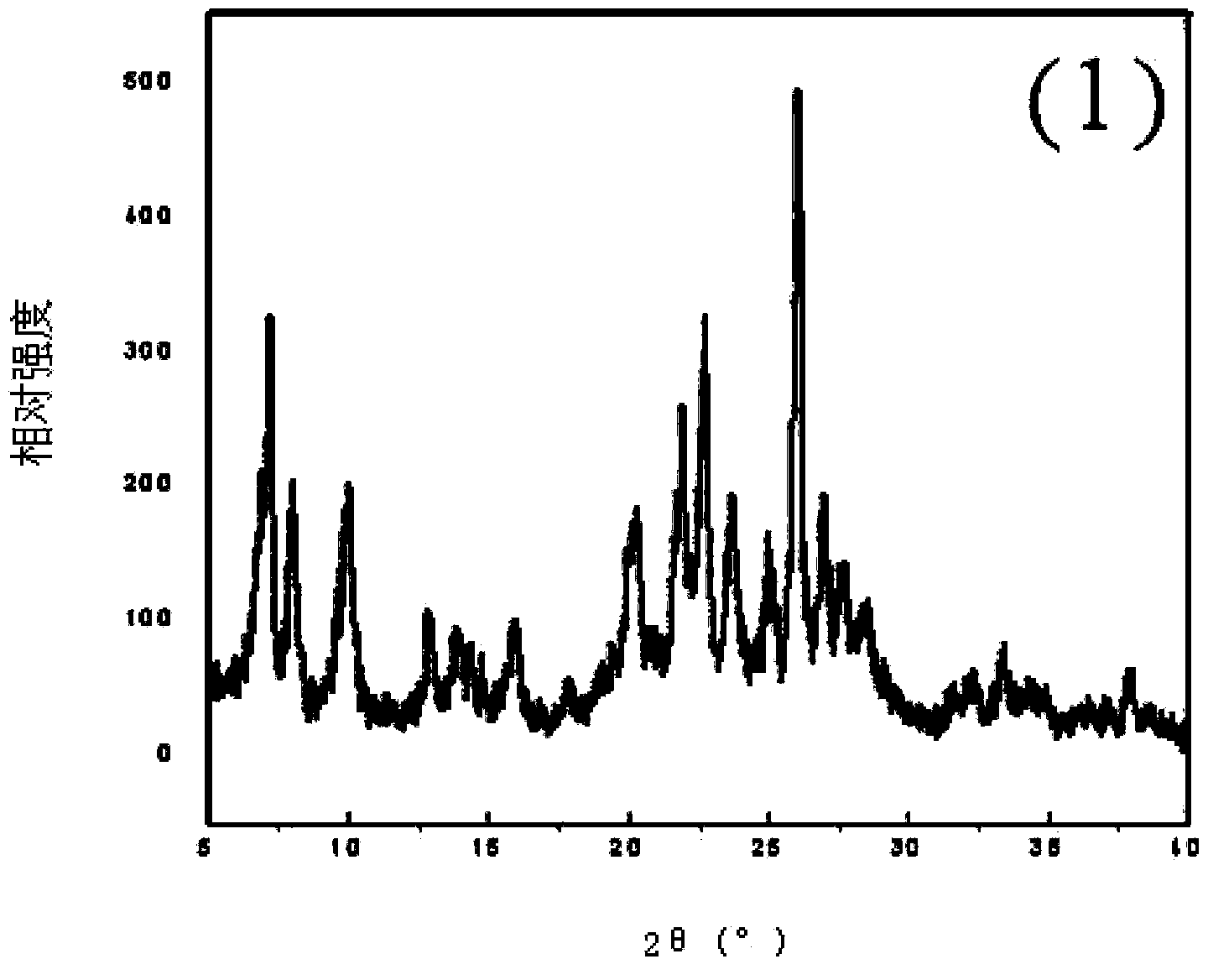

Embodiment 1

[0032] 2.1kg of sodium metaaluminate and 0.14kg of sodium hydroxide are completely dissolved in 50kg of desalinated water to prepare sodium metaaluminate-sodium hydroxide aqueous solution; 52kg of silica sol with a mass content of 25%-30% is added to 1kg of ethyl silicate , fully stirred to obtain a silica sol-ethyl silicate emulsion; 5kg of hexamethyleneimine was added to 5kg of cyclohexylamine, and fully stirred to obtain a hexamethyleneimine-cyclohexylamine binary template agent. Add the silica sol-ethyl silicate emulsion into the gel forming tank, start stirring, add hexamethyleneimine-cyclohexylamine binary template, stir evenly, add sodium metaaluminate-sodium hydroxide aqueous solution dropwise, until After the "thick point", increase the stirring speed, open the gel, slowly add the remaining sodium metaaluminate-sodium hydroxide aqueous solution; then add 0.5kg NaMCM-49 molecular sieve, stir for 2 hours, and proceed to gelation.

[0033] Put the gelled slurry into a 1...

Embodiment 2

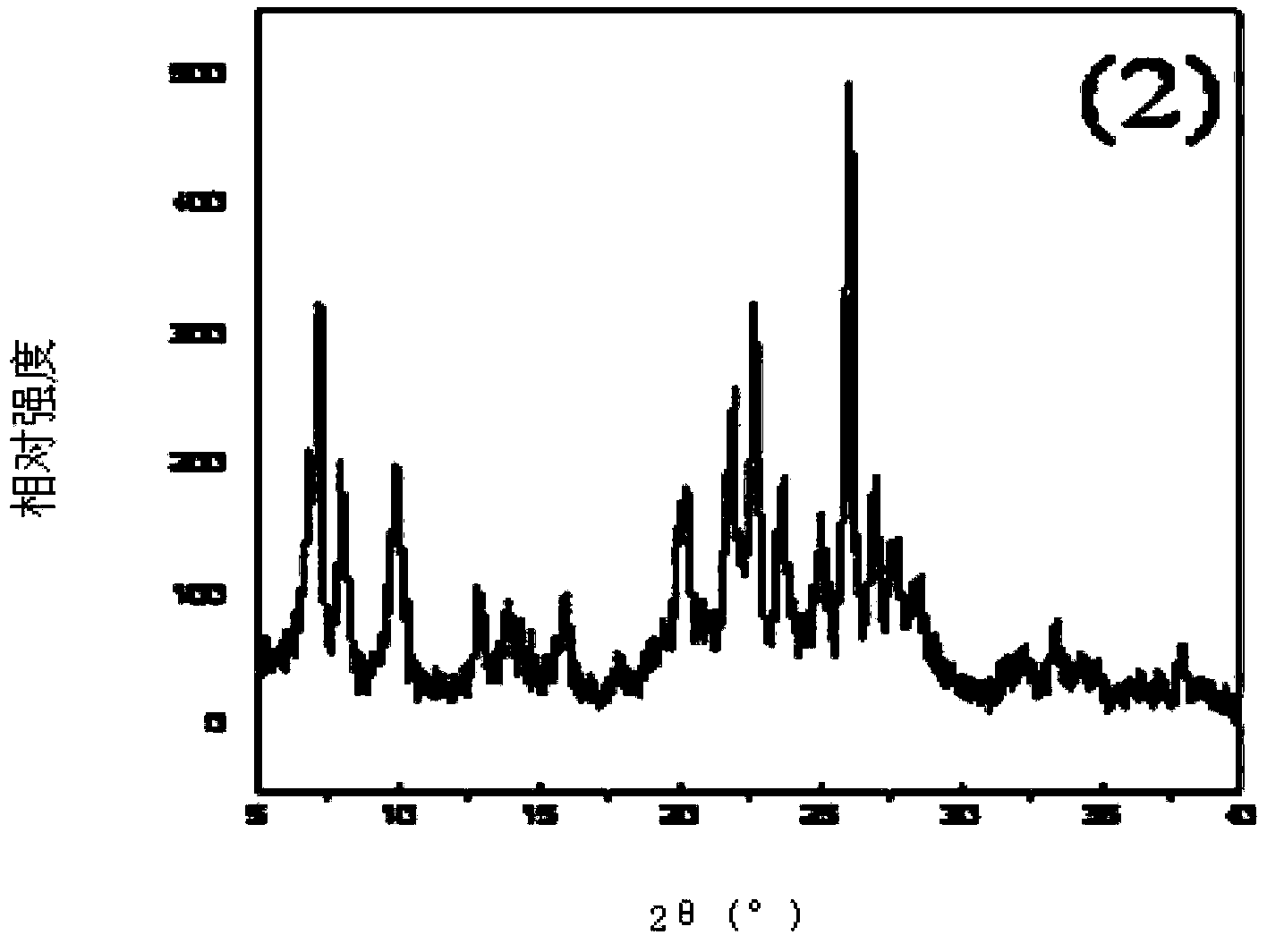

[0035] Dissolve 2.1kg of sodium metaaluminate and 0.084kg of sodium hydroxide completely in 50kg of desalinated water to prepare sodium metaaluminate-sodium hydroxide aqueous solution; add 52kg of silica sol with a mass content of 25%-30% to 1.3kg of ethyl silicate In the ester, stir fully to obtain a silica sol-ethyl silicate emulsion; add 7.5kg of hexamethyleneimine to 2.5kg of cyclohexylamine, and stir thoroughly to obtain hexamethyleneimine-cyclohexylamine di Metatemplating agent. Add the silica sol-ethyl silicate emulsion into the gel forming tank, start stirring, add hexamethyleneimine-cyclohexylamine binary template, stir evenly, add sodium metaaluminate-sodium hydroxide aqueous solution dropwise, until After the "thick point", increase the stirring speed, open the gel, slowly add the remaining sodium metaaluminate-sodium hydroxide aqueous solution; then add 0.6kg NaMCM-49 molecular sieve, stir for 4 hours, and proceed to gelation.

[0036] Put the gelled slurry into a...

Embodiment 3

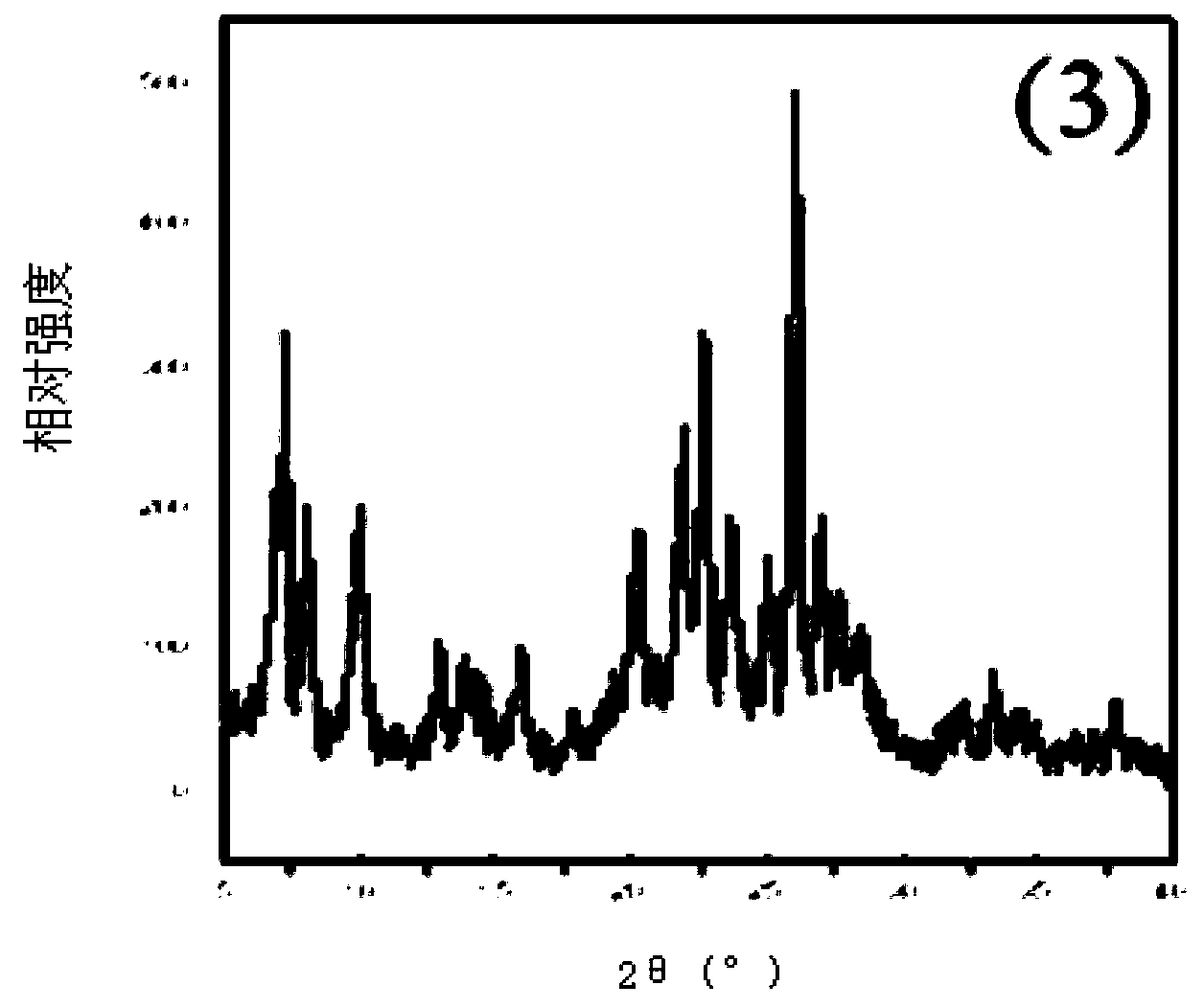

[0038]2.1kg of sodium aluminate and 0.1kg of sodium hydroxide are completely dissolved in 50kg of desalted water to prepare sodium metaaluminate-sodium hydroxide aqueous solution; 52kg of silica sol with a mass content of 25%-30% is added to 1.2kg of ethyl silicate , fully stirred to obtain a silica sol-ethyl silicate emulsion; add 6kg of hexamethyleneimine to 4kg of cyclohexylamine, and fully stir to obtain a hexamethyleneimine-cyclohexylamine binary template . Add the silica sol-ethyl silicate emulsion into the gel forming tank, start stirring, add hexamethyleneimine-cyclohexylamine binary template, stir evenly, add sodium metaaluminate-sodium hydroxide aqueous solution dropwise, until After the "thick point", increase the stirring speed, open the gel, slowly add the remaining sodium metaaluminate-sodium hydroxide aqueous solution; then add 0.4kg NaMCM-49 molecular sieve, stir for 3 hours, and proceed to gelation.

[0039] Put the gelled slurry into a 100L crystallization k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com