Synthetic method of solution-polymerized styrene-butadiene rubber

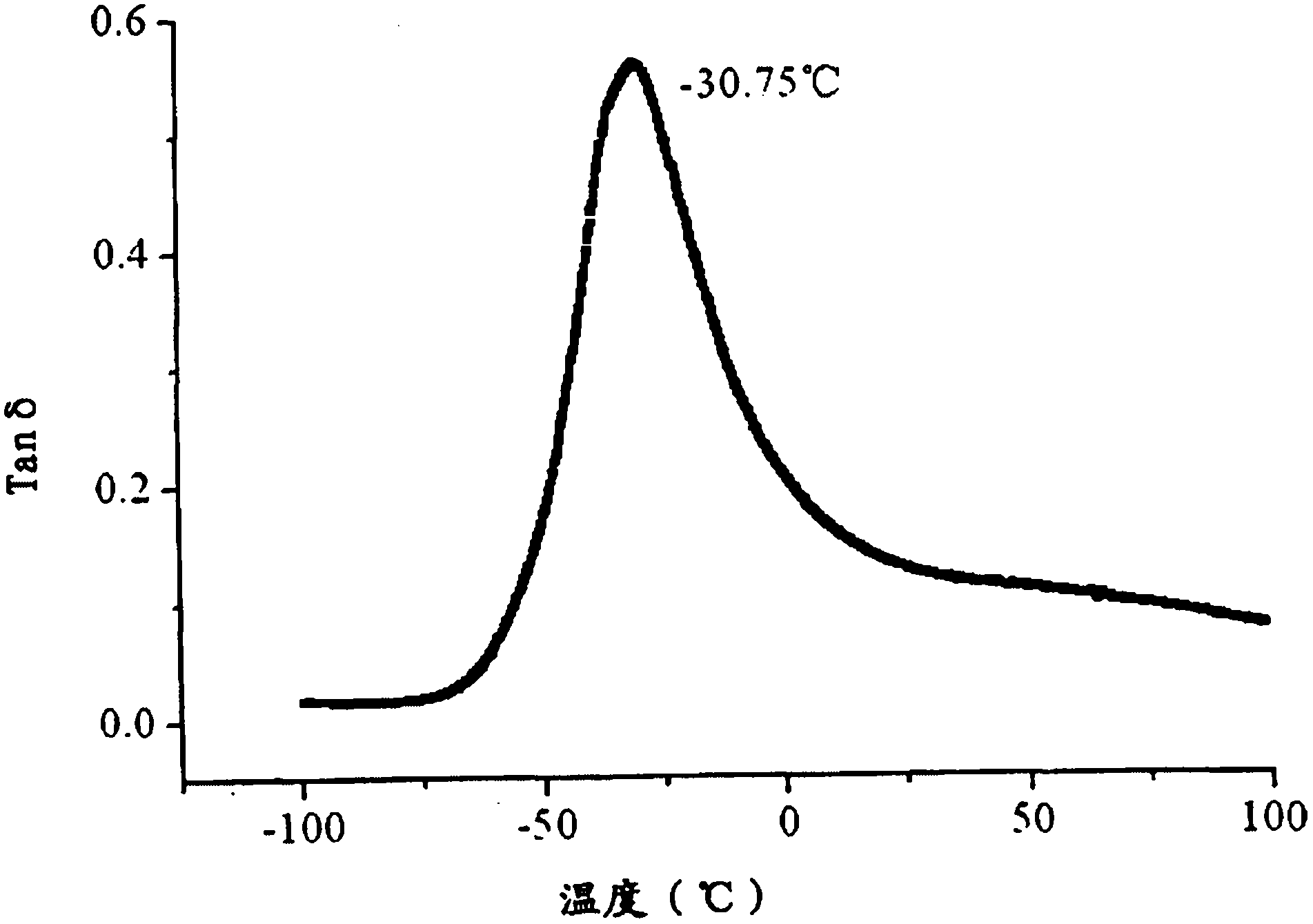

A solution-polymerized styrene-butadiene rubber and synthesis method technology, which is applied in the field of solution-polymerized styrene-butadiene rubber synthesis, can solve the problems of narrow temperature range in the high damping area, affecting the use of products in the field of damping and shock absorption, and affecting the use of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below. In the method of the present invention, the polymerized monomer used is a mixture of butadiene and styrene, wherein the content of styrene is 10-50% based on the total mass of the monomers, and the content of butadiene is correspondingly 90-50%. In the method of the present invention, used hydrocarbon solvent is the mixed solvent of cyclohexane, raffinate or cyclohexane and normal hexane (the weight ratio of cyclohexane and normal hexane is 90: 10-70: 30), so The solvent is used in such an amount that the monomer concentration is 10% to 20% by weight.

[0010] In the method of the present invention, the initiator used is any one selected from the following compounds: C, -C, alkyllithium, CG-C1: aryllithium, CT-C1+ aralkyllithium or C3-CG ring Alkyllithium, such as ethyllithium, propyllithium, isopropyllithium, n-butyllithium, sec-butyllithium, pentyllithium, hexyllithium, cyclohexyllithium, phenyllithium, methylphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com