Method for preparing aerospace-level vanadium-aluminium alloy

A vanadium-aluminum alloy and aerospace technology, applied in the field of preparing aerospace-grade vanadium-aluminum alloy, can solve the problems of complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the vanadium aluminum alloy according to the exemplary embodiment of the present invention comprises the following steps:

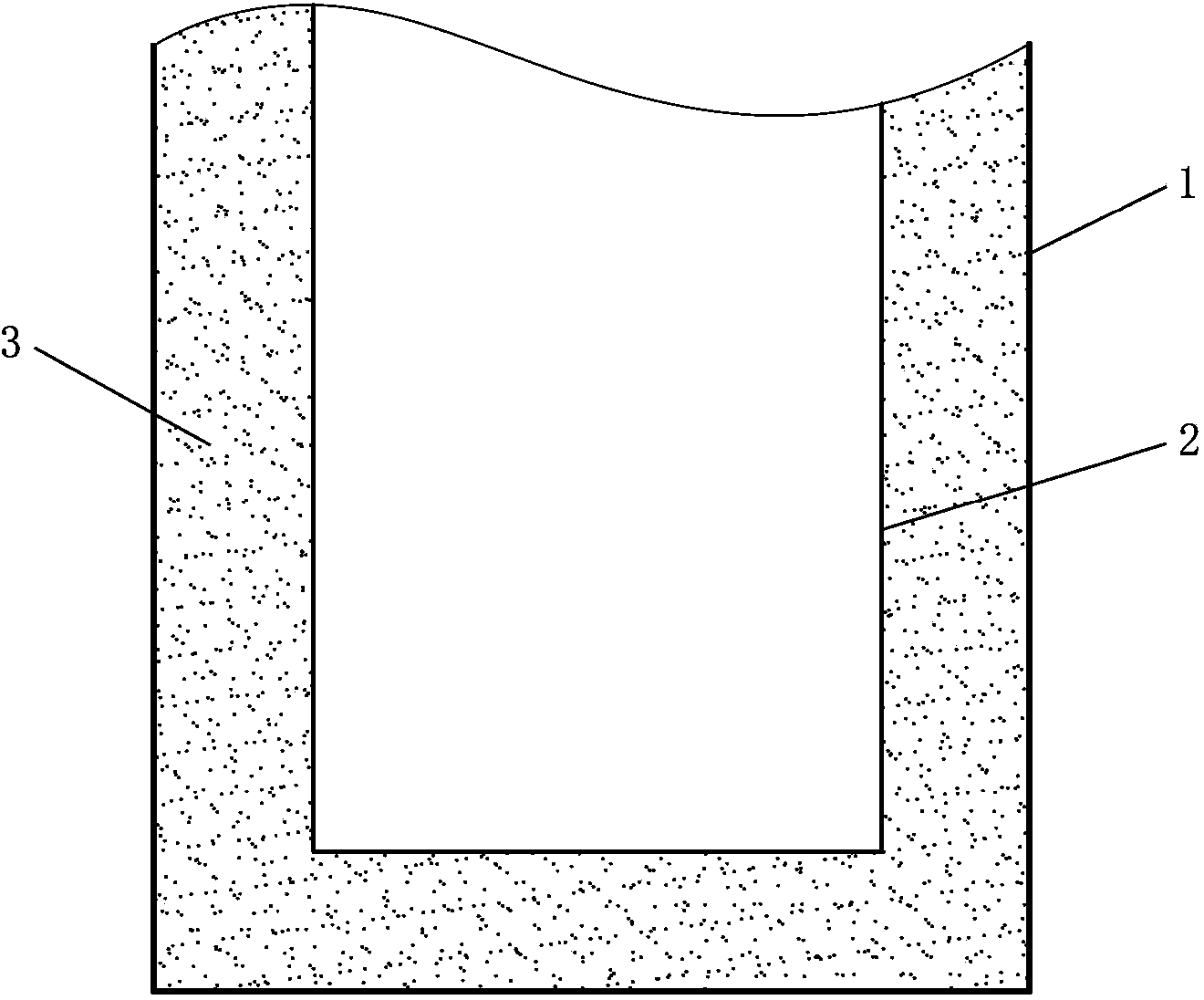

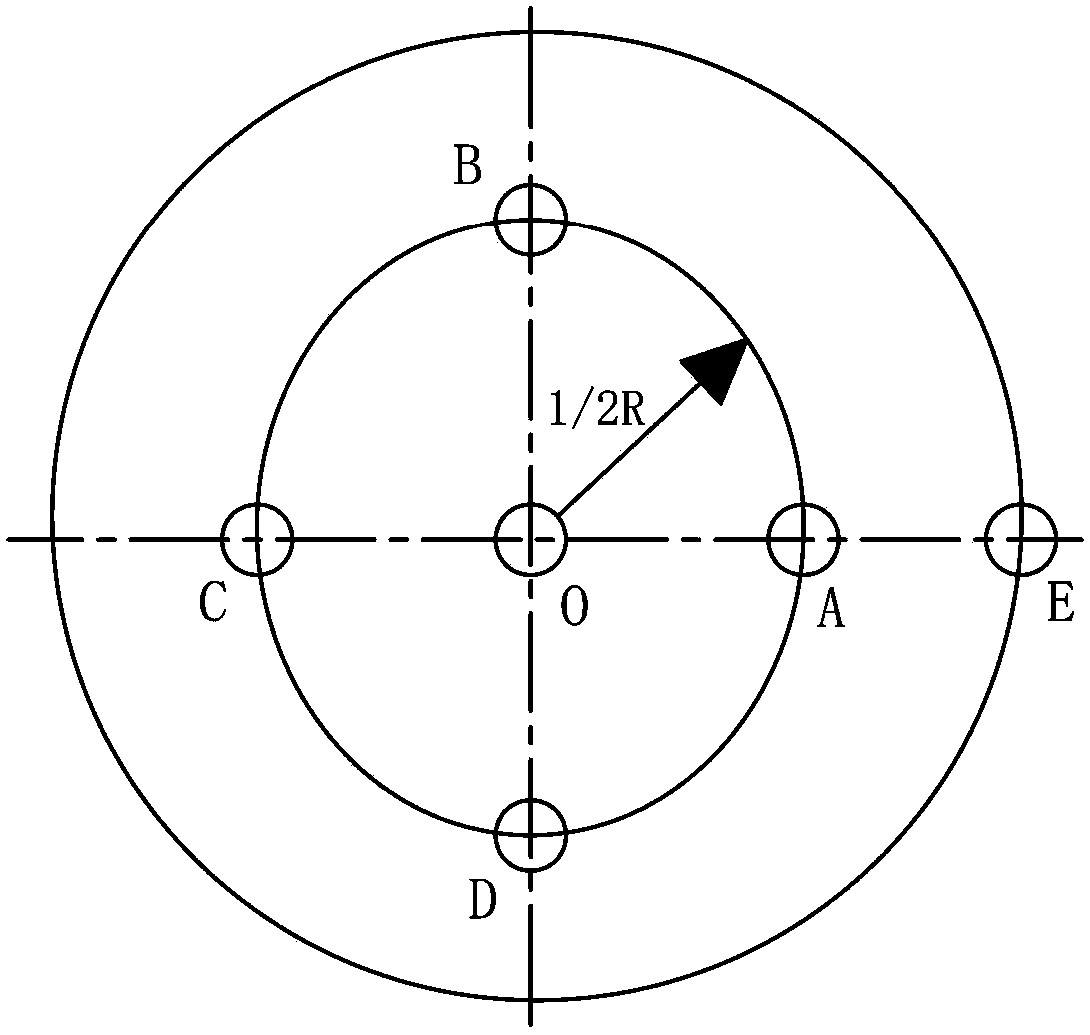

[0025] a. If figure 1 As shown, corundum fine powder 3 with a particle size of less than 5 mm is laid on the bottom of the smelting furnace, and a cylindrical plate 2 (such as a cylindrical steel ring) with a diameter smaller than the diameter of the smelting furnace is vertically placed in the smelting furnace and placed toward the cylindrical plate 2 The cavity formed between the furnace shell 1 and the inner wall of the smelting furnace is filled with corundum fine powder 3 to form a protective layer on the bottom and wall of the smelting furnace to prevent the molten metal in the furnace from directly contacting the furnace shell, and then take it out Cylindrical plate 2.

[0026] b. The aluminothermic method is used for smelting, and the vanadium pentoxide, metal aluminum and coolant are evenly mixed and loaded into ...

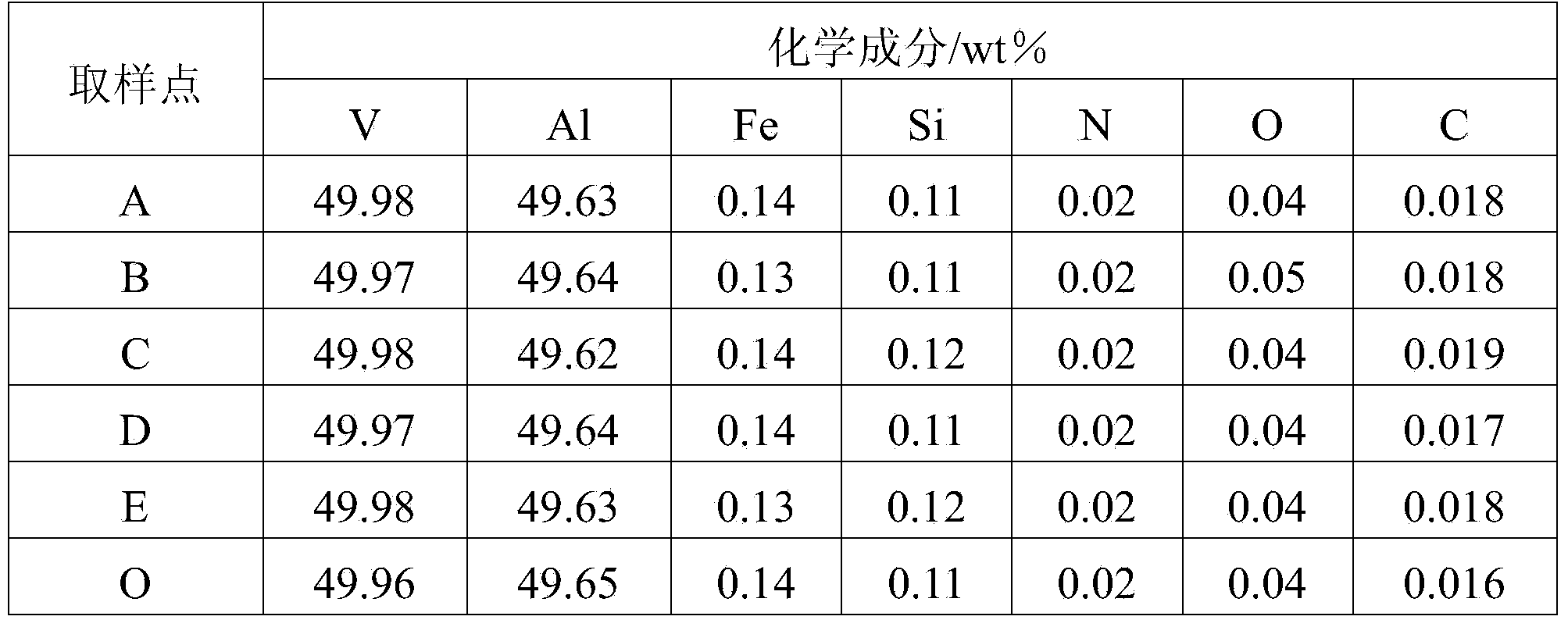

example 1

[0037] First, lay corundum fine powder with a particle size of less than 5mm on the bottom of the smelting furnace, put a cylindrical steel ring with a diameter smaller than the diameter of the smelting furnace into the smelting furnace, and fill the cavity formed between the steel ring and the inner wall of the smelting furnace with corundum fine powder to form a protective layer with a thickness of 280mm on the furnace bottom and furnace wall of the smelting furnace, wherein the corundum fine powder is the slag produced by the smelting of the vanadium-titanium alloy crude product in the previous furnace, and the particle size obtained by grinding and screening is less than 5mm powder.

[0038] Then, 150Kg high-purity powdered vanadium pentoxide (purity 99.5wt%, particle size 0.5-1mm), 100Kg aluminum powder (purity 99.7wt%, particle size 0.1-0.5mm) and 28Kg coolant powder were mixed evenly Then put it into the smelting furnace and ignite to obtain the crude vanadium-aluminum ...

example 2

[0045] First, lay corundum fine powder with a particle size of less than 5mm on the bottom of the smelting furnace, put a cylindrical plate with a diameter smaller than the diameter of the smelting furnace into the smelting furnace, and insert it into the cavity formed between the cylindrical plate and the inner wall of the smelting furnace Fill the corundum fine powder to form a protective layer with a thickness of 300mm on the furnace bottom and furnace wall of the smelting furnace, wherein the corundum fine powder is the slag produced by smelting the crude vanadium-titanium alloy in the previous furnace after grinding and screening obtained powder.

[0046] Then mix 160Kg powdered vanadium pentoxide (purity 99.5wt%, particle size 0.5-0.8mm), 100Kg aluminum powder (purity 99.7wt%, particle size 0.1-0.3mm) and 32Kg coolant powder evenly before loading into the smelting furnace and ignited to obtain crude vanadium-aluminum alloys, wherein the coolant is alloy fine powder with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com