Method of reversely electroforming bionic replica surface directly by thin and brittle type biological surface

A biological surface, thin and brittle technology, applied in the direction of electroforming, electrolysis, etc., can solve the problems of biological prototypes that are light and thin, difficult to handle, difficult, and difficult to directly obtain a hard bionic replica surface at one time, so as to avoid negative templates The effect of the mold turning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

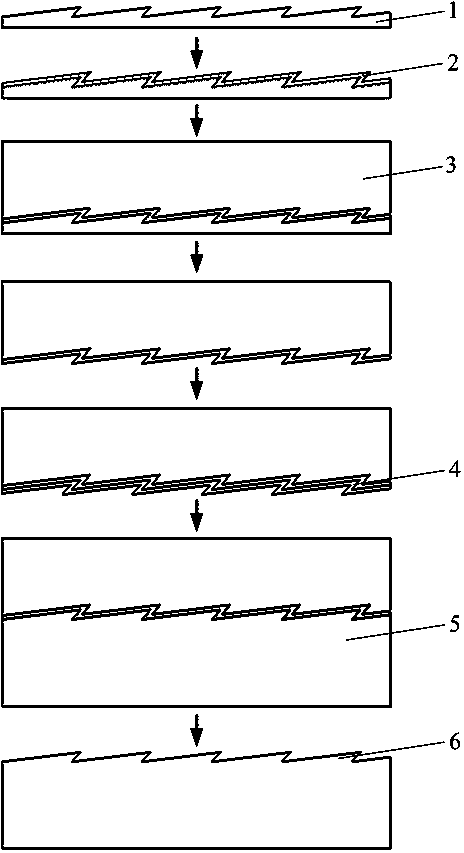

[0040] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings, taking the reverse electroforming directly from the butterfly wing surface as a specific example to further illustrate the present invention.

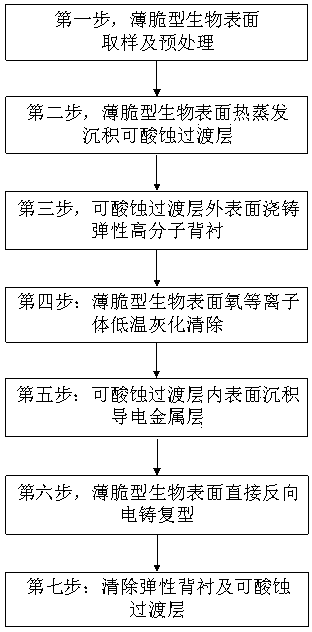

[0041] see figure 1 , figure 2 As shown, the present invention directly produces the method for imitating the butterfly wing surface by the reverse electroforming of the butterfly wing surface, comprising the following steps:

[0042] Step 1: Surface sampling and pretreatment of butterfly wings

[0043] (A) The surface of butterfly wings was sampled, washed four times with deionized water, and then chemically fixed in a glutaraldehyde solution with a concentration of 2.5% by mass at 4°C for 4 hours to obtain a fixed surface sample;

[0044](B) Wash the fixed surface samples prepared in step (A) three times w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com