Monitoring method for grouting compaction of pre-stressed pipe based on piezoelectric ceramic

A technology of prestressed pipes and piezoelectric ceramics, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of low monitoring efficiency, difficulty in judging test results, and influence of test results by shock echo method, and achieve Rapid detection, sensitive response, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

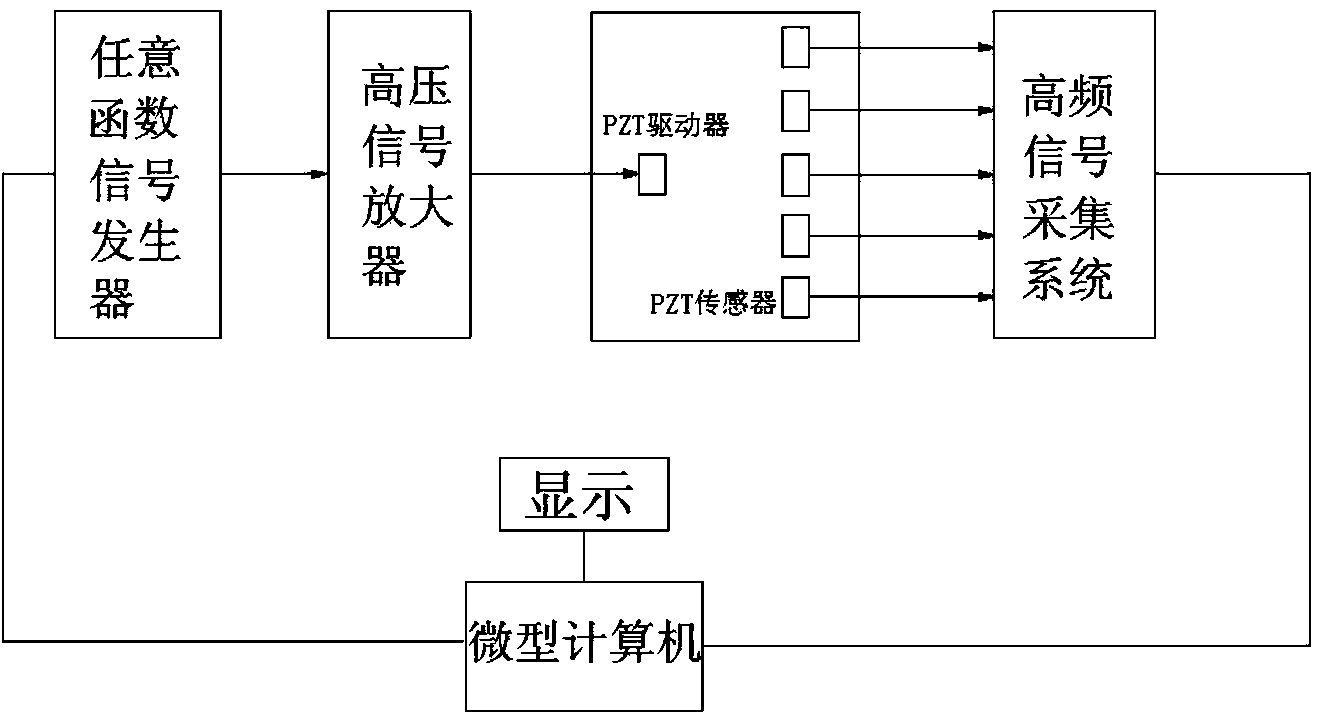

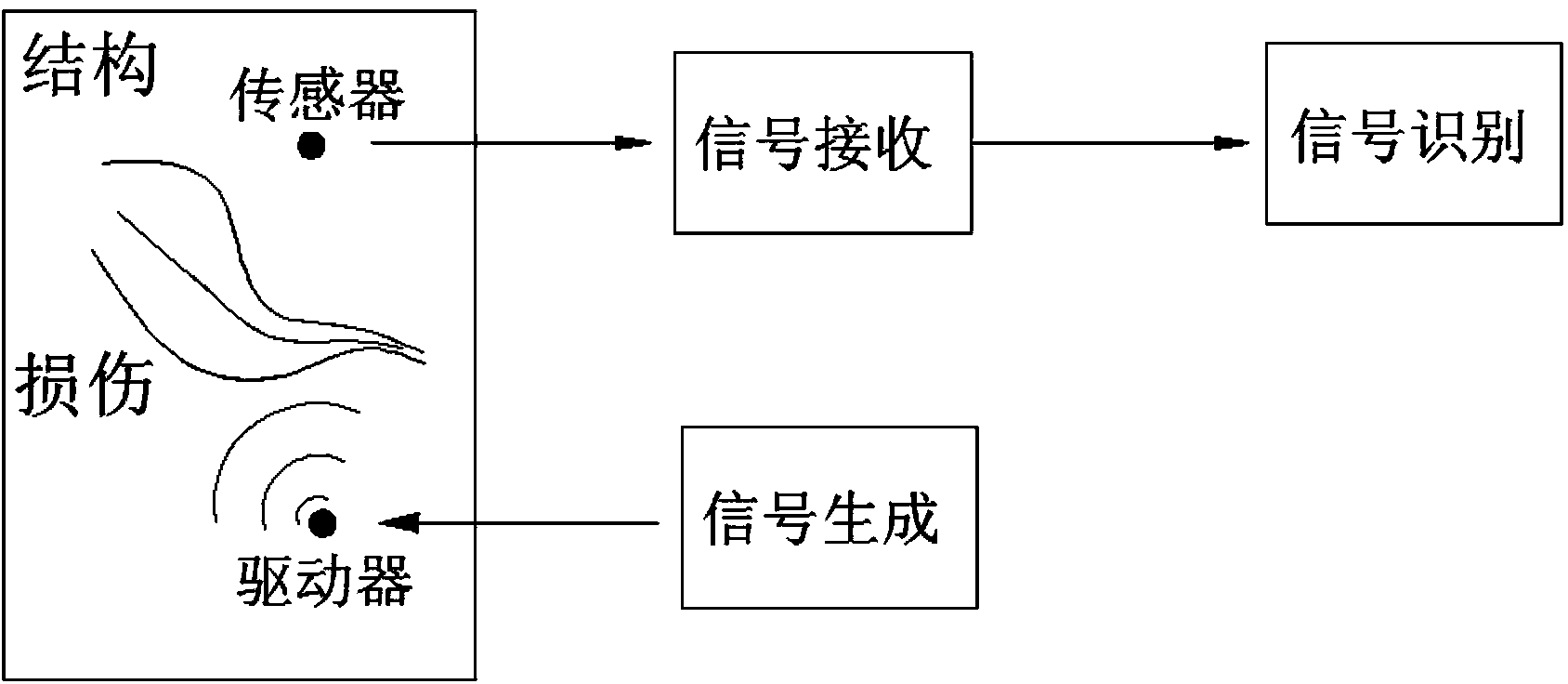

Method used

Image

Examples

Embodiment

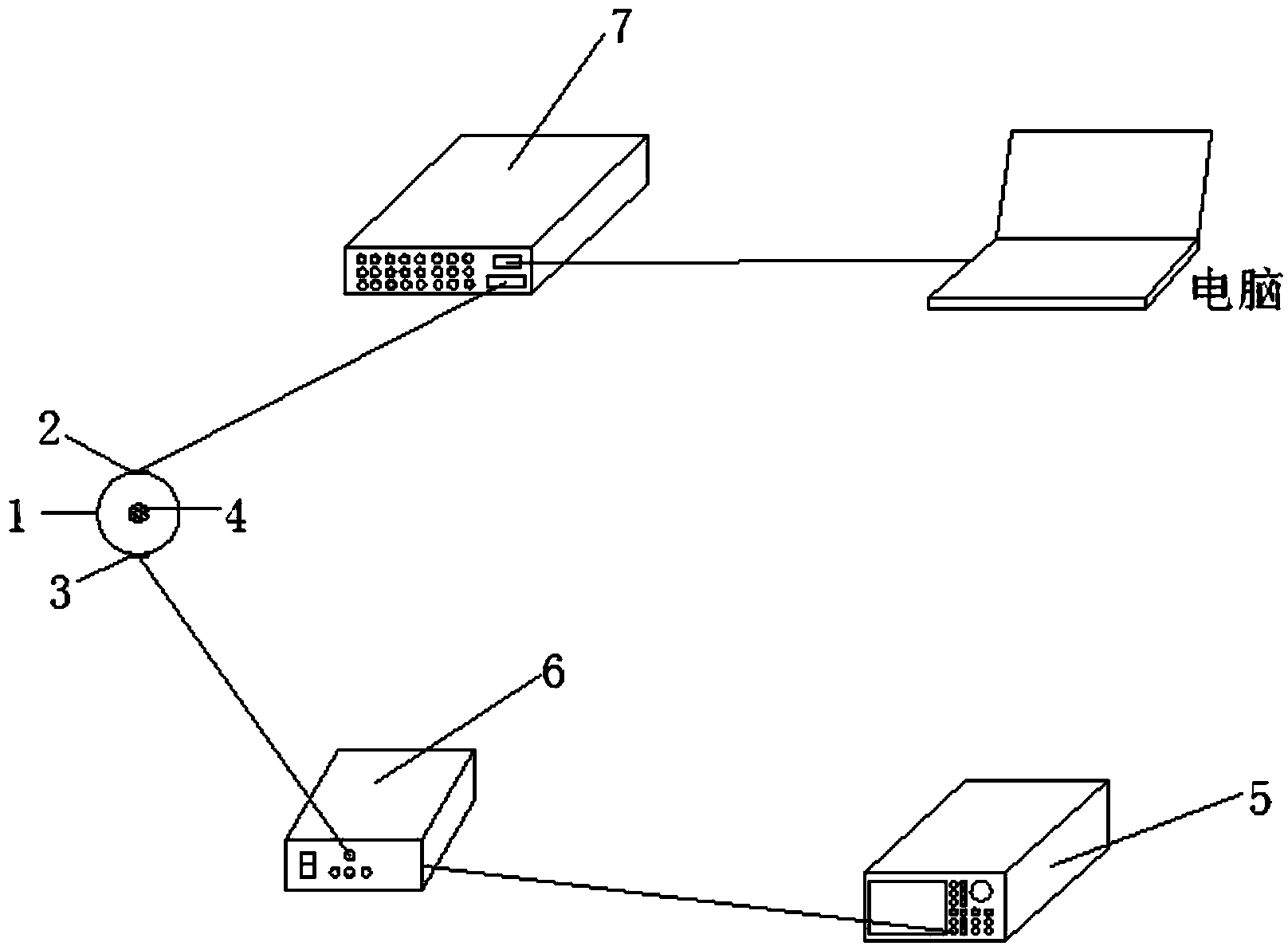

[0043] Such as Figure 4 As shown, a piezoelectric ceramic sheet is pasted on the top and bottom of a prestressed corrugated pipe as a sensor and a driver respectively, and a layer of bisphenol A epoxy resin waterproof layer is coated on the piezoelectric ceramic sheet.

[0044] The sticking position of the piezoelectric ceramic sheet is pre-coated with an insulating layer, and the insulating layer is a uniform epoxy resin insulating layer.

[0045] The specific operation steps of the monitoring method in this example are:

[0046] a. If Figure 4 As shown, seven prestressed steel strands with a nominal diameter of 15.2mm are stretched in a circular prestressed bellows with an inner diameter d of 60mm, an outer diameter D of 73mm, and a nominal wall thickness of 2.5mm, grouting, and natural curing. , Pour C40 concrete after sealing the anchor. Concrete with a length and width of 300×300mm is made as a beam body specimen. The length of the specimen shall be determined accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com