Structure for monitoring etching back depth and monitoring method

A deep, wafer technology, used in electrical components, circuits, semiconductor/solid-state device testing/measurement, etc., can solve the problems of increasing the initial cost of testing, expensive stepper, large maintenance cost, etc., to achieve cost reduction, better Practical, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] As mentioned in the background, the existing monitoring methods for polysilicon etch-back depth of trench DMOS devices are either to perform destructive testing on wafer chips, or to use expensive instruments for testing, both of which are costly , The monitoring method is too complicated and other defects, so it cannot meet the requirements of assembly line production.

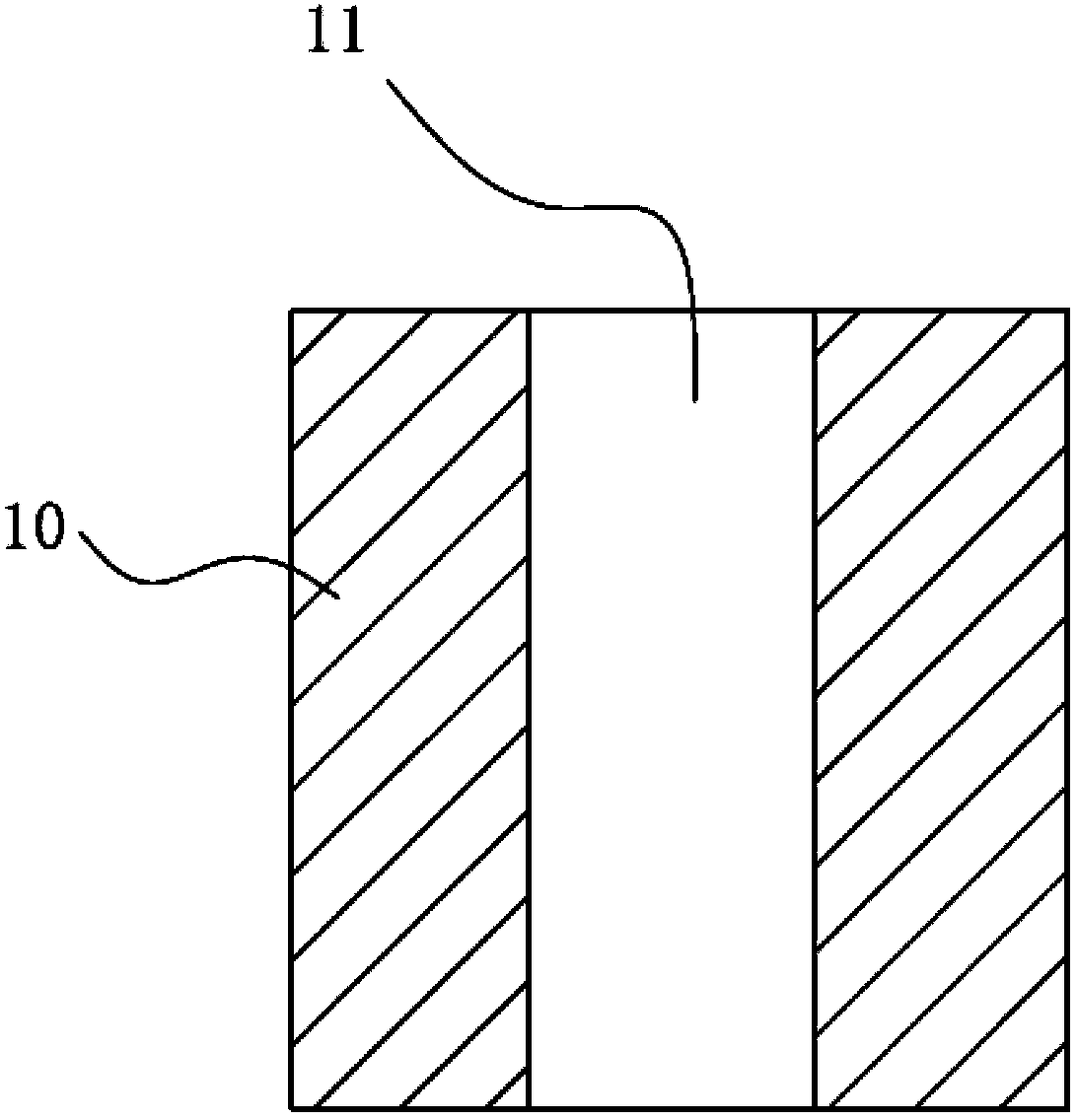

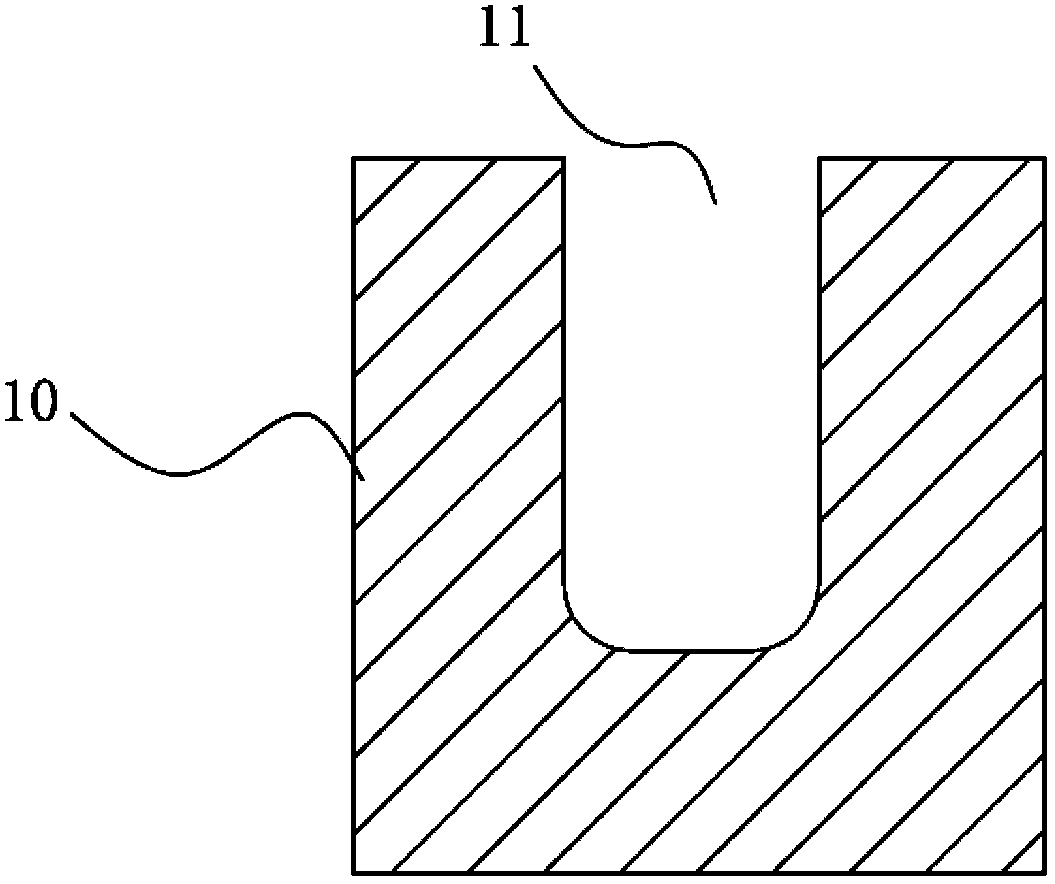

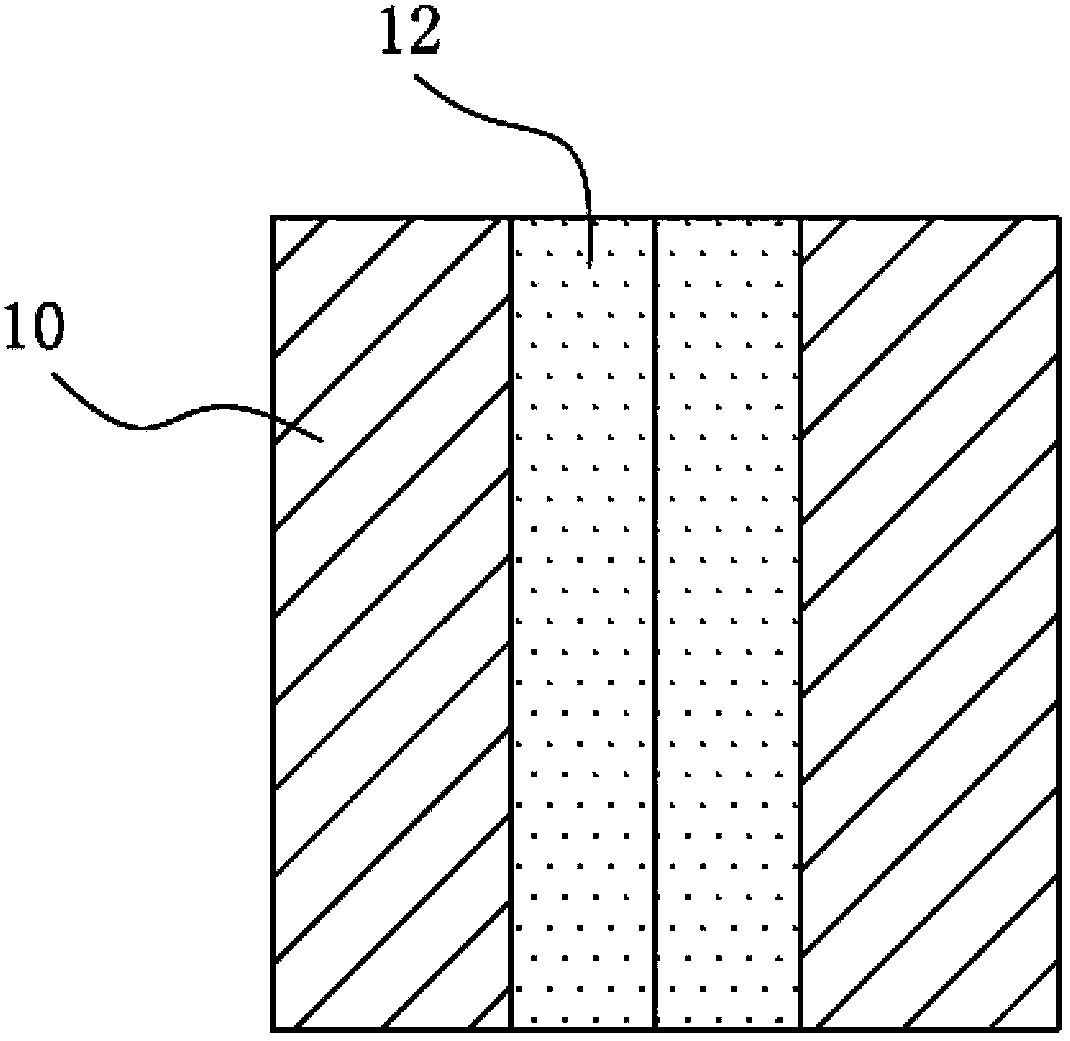

[0038] Therefore, aiming at the defects in the prior art, the present invention proposes a monitoring structure and method for engraving back depth. The monitoring structure is made in the non-element area of the wafer substrate, and is a groove with a special structure. After the groove undergoes a polysilicon etching process, the polysilicon can be divided into a blank area and a filling area in the groove. And at the junction of the two regions, an obvious polysilicon inflection point appears. Using the position where the inflection point appears in the monitoring structure, the corresponding etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com