Mixed type LED illumination circuit and control strategy thereof

A technology of LED lighting and LED circuit, applied in the field of LED light source, can solve problems such as heat dissipation difficulties, energy consumption of external current limiting resistors, damage of LED chips, etc., and achieve high efficiency, low cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

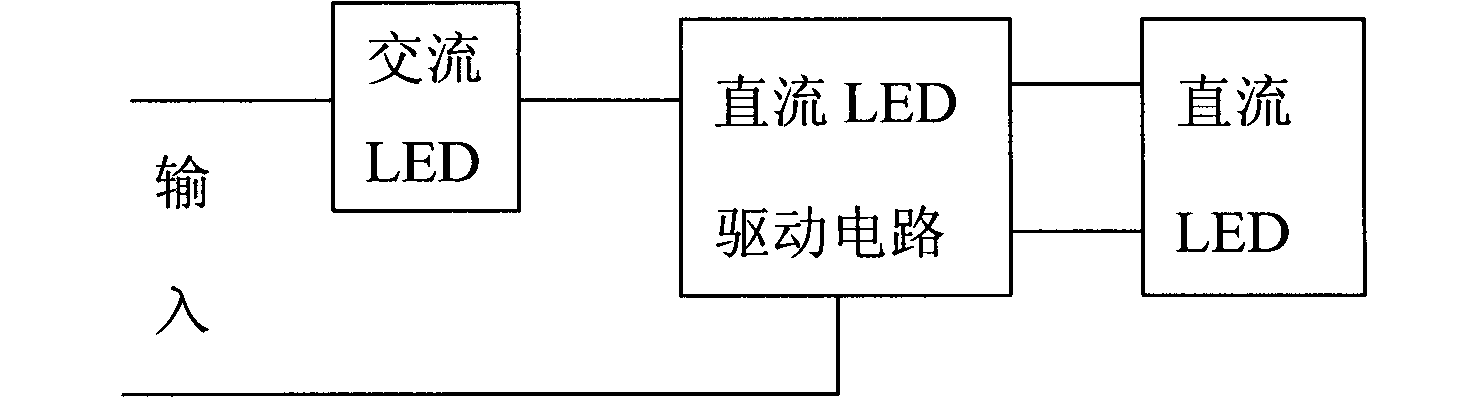

[0051] Embodiment 1 AC-DC Hybrid Circuit and Its Current Control and Power Control Strategy

[0052] figure 1 It is a schematic diagram of the principle of an AC-DC hybrid circuit, in which the AC LED is connected in series with the AC input end of the rectifier circuit of the DC LED drive circuit (the drive circuit includes a rectifier circuit), and the DC LED drive input side is called the DC side, and the DC LED drive output side is called the DC side. On the low-voltage side, the voltage on the DC side is u1, the voltage across the LEDs connected in series on the DC side is U2, and the voltage across the LEDs connected in series on the low-voltage side is U3. Due to the small internal resistance of the LED, U2 and U3 can take the LED threshold voltage for rough control Near fixed value, set the target current as i1r, and the current control strategy is:

[0053] Step 1: Obtain i2ref from given i1r, i2ref=i1r×u1÷U3;

[0054] Step 2: Limit i2ref, take the smaller of i2ref ...

Embodiment 2

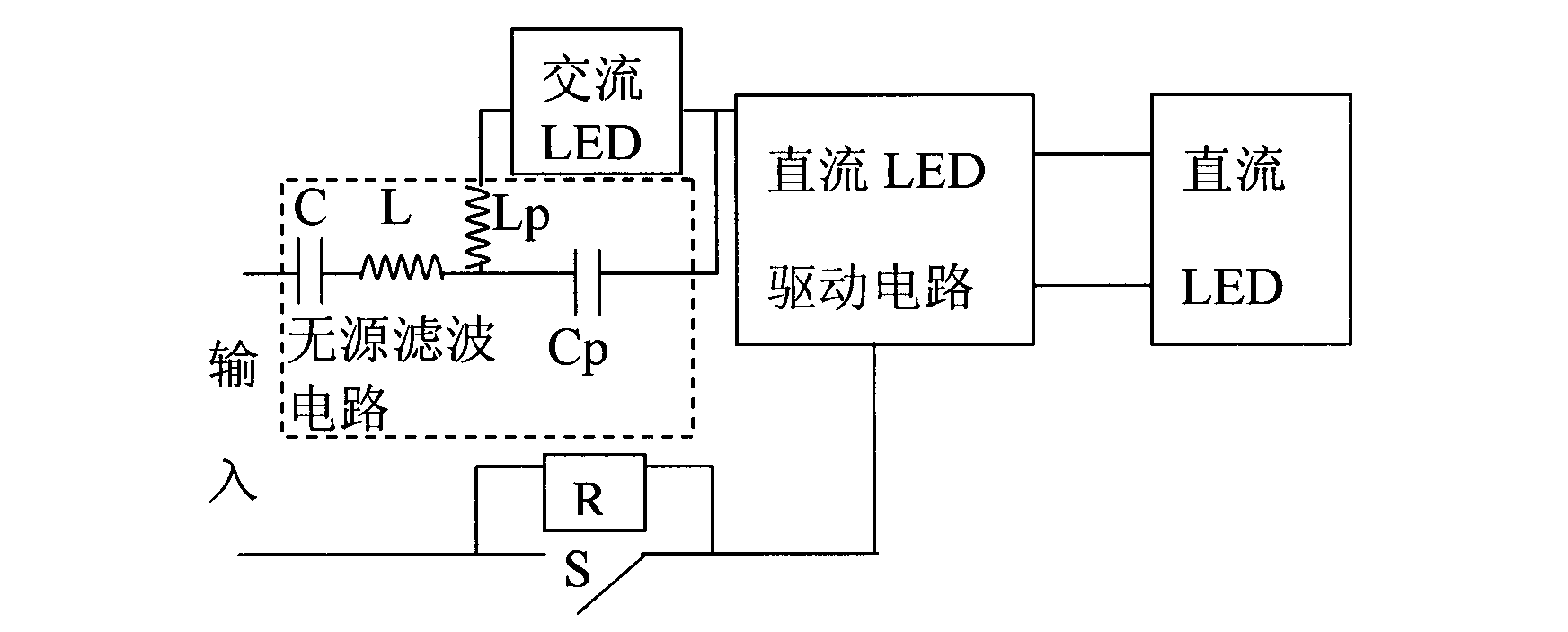

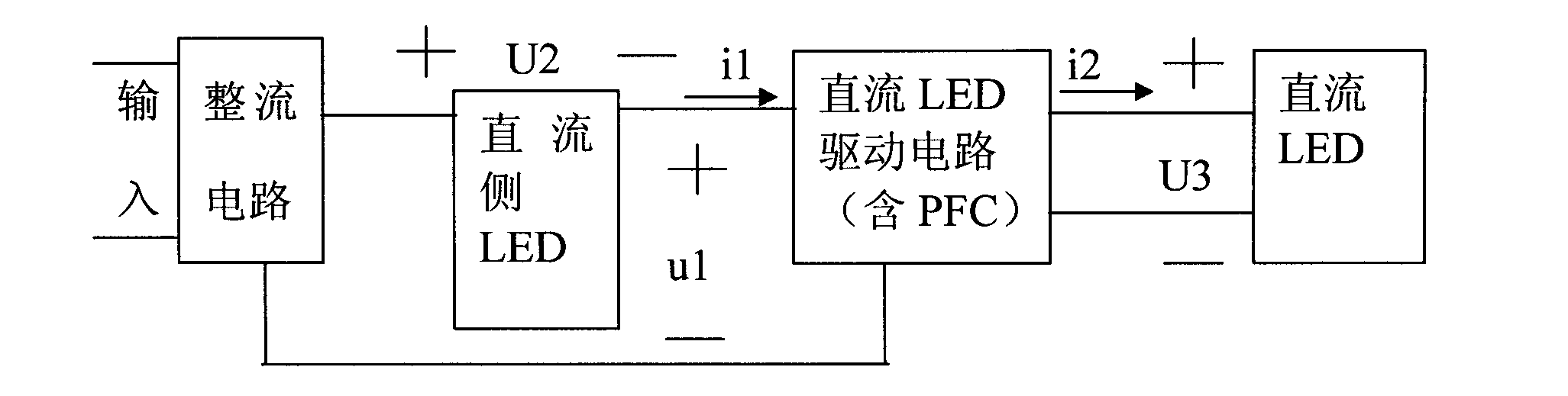

[0067] Embodiment 2 DC Hybrid Circuit and Current and Power Control Strategy

[0068] image 3 , Figure 4 It is a schematic diagram of the principle of the DC hybrid circuit. The DC side LED is connected to the DC side power supply circuit of the DC LED drive circuit through a passive filter circuit or a parallel reverse voltage regulator diode or directly connected in series. image 3 Medium DC LED drive circuit includes PFC circuit, Figure 4 The middle rectifier circuit includes a PFC circuit, and the DC LED driver circuit does not include a PFC circuit. The DC side LED shares the input voltage of the DC LED driver, reducing the working voltage and output power of the DC LED driver, resulting in lower cost and higher efficiency. Let the input side of the DC LED drive be called the DC side, and the output side of the DC LED drive be called the low-voltage side. image 3 and Figure 4 The LED box on the middle DC side represents that the DC LED is connected in parallel wit...

Embodiment 3

[0075] Embodiment 3 AC-DC Hybrid Circuit Working at Higher Frequency

[0076] Figure 5 It is a schematic diagram of an AC-DC hybrid circuit working at a higher frequency. Figure 5 In the AC LED, the DC LED reverse-parallel voltage regulator diode is connected across the output end of the passive filter circuit, the output end of the passive filter circuit is connected across the output end of the half-bridge rectifier circuit, and the AC side of the half-bridge rectifier circuit is connected to the band The secondary side of the center-tapped transformer and the primary side of the transformer are connected in series with the DC LED drive circuit and the current limiting resistor R protection circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com