Self-walking type corn combine harvester

A combine harvester and self-propelled technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as difficulty in exerting high-horsepower engines, blockage of engine cooling water tanks, and engine overheating, so as to improve heat dissipation and ventilation effect, put an end to bracts that cannot be crushed, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

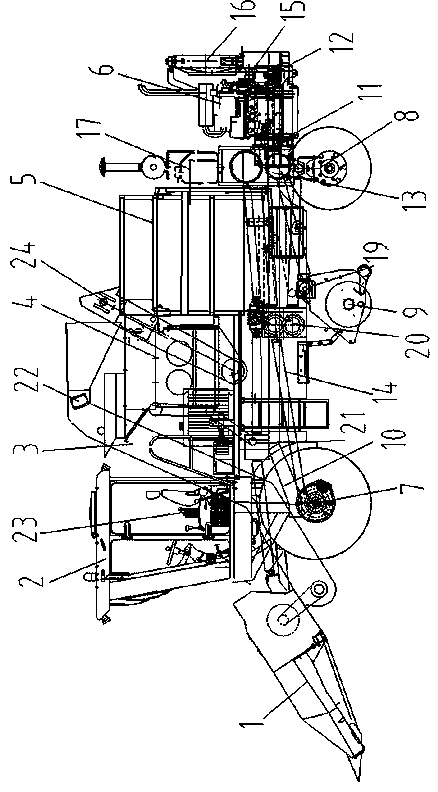

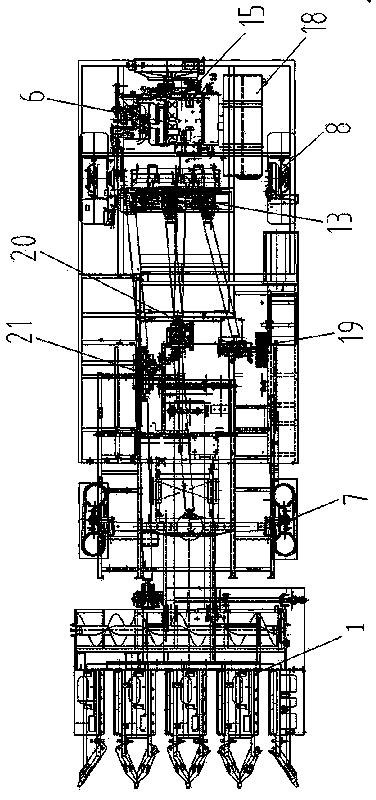

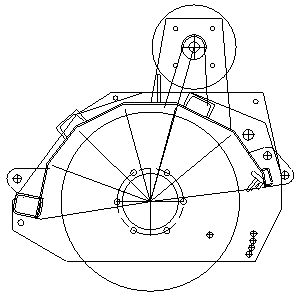

[0013] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The self-propelled corn combine harvester takes the frame 10 as the carrier, and the upper part of the frame 10 is respectively a corn cutting platform 1, a cab 2, an ear lifter 3, an ear peeler 4, an ear bin 5, engine6. A front axle assembly 7 and a rear axle assembly 8 are respectively arranged at the front and rear ends of the lower part of the frame 10, and a straw crushing and returning machine 9 is arranged between the front axle assembly 7 and the rear axle assembly 8.

[0014] The engine 6 is located at the tail of the self-propelled corn combine harvester. The engine 6 has changed the traditional horizontal layout and adopted a vertical installation layout. The gear box 13 is connected, and the power is divided into three ways to transmit the power to the walking system 14, the straw crushing and returning machine 9, the corn cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com