Air filter material containing active carbon and production method thereof

A technology for air filter materials and production methods, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, and can solve the problems of inability to absorb harmful gases, inability to remove acidic or alkaline or compound volatile harmful gases, and ineffective Remove acidic or alkaline or complex volatile harmful gases, etc., to achieve high removal rate and good removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

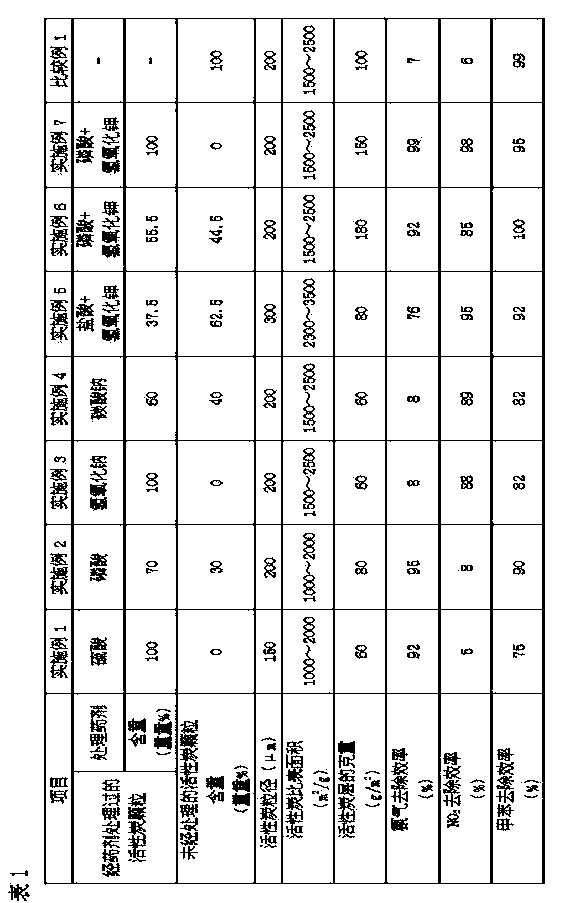

Embodiment 1

[0028] (1) Sulfuric acid was sprayed onto activated carbon particles by spraying, and then dried at a temperature of 80-90°C to obtain activated carbon particles treated with sulfuric acid. The average particle size of the activated carbon particles was 150μm and the ratio The surface area is 1000~2000m 2 / g;

[0029] (2) The activated carbon particles treated with sulfuric acid are directly mixed with hot melt adhesive powder and sprinkled on a layer of non-woven fabric, and then combined with another layer of non-woven fabric by heat treatment at a temperature of 130°C for 2 minutes , The final formation contains 60g / m 2 Activated carbon air filter material, the removal efficiency of the air filter material to ammonia gas is 92%, NO 2 The removal efficiency of toluene is 5%, and the removal efficiency of toluene is 75%.

Embodiment 2

[0031] (1) The activated carbon particles are immersed in phosphoric acid, and then dried at a temperature of 80-90°C to prepare activated carbon particles treated with phosphoric acid. The average particle size of the activated carbon particles is 200μm and the specific surface area is 1000-2000m. 2 / g;

[0032] (2) The activated carbon particles treated with phosphoric acid and the activated carbon particles not treated with acid-base treatment are blended at a weight ratio of 70:30, and then mixed with hot melt adhesive powder and sprinkled on a layer of non-woven fabric. Then through the heat treatment at a temperature of 120°C and a time of 3 minutes, it is combined with another layer of non-woven fabric to form a final weight of 80g / m 2 Activated carbon air filter material, the removal efficiency of the air filter material to ammonia gas is 95%, NO 2 The removal efficiency of toluene is 8%, and the removal efficiency of toluene is 90%.

Embodiment 3

[0034] (1) Sodium hydroxide is sprayed onto the activated carbon particles by spraying, and then dried at a temperature of 80-100 ℃ to obtain activated carbon particles treated with sodium hydroxide. The average particle size of the activated carbon particles 200μm, specific surface area is 1500~2500m 2 / g;

[0035] (2) The activated carbon particles treated with sodium hydroxide are directly mixed with hot melt adhesive powder and then sprinkled on a layer of non-woven fabric, and then heat-treated with another layer of non-woven fabric at a temperature of 130°C for 2 minutes Compound processing, the final formation is 60g / m 2 Activated carbon air filter material, the removal efficiency of the air filter material to ammonia gas is 8%, NO 2 The removal efficiency of toluene is 88%, and the removal efficiency of toluene is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com