Method for processing high-polymer raw material cork particles

A technology of cork particles and processing methods, which is applied to wood processing equipment and manufacturing tools, etc., can solve the problems of large labor investment, low processing efficiency, low utilization rate of raw materials, etc., and achieve the effect of eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

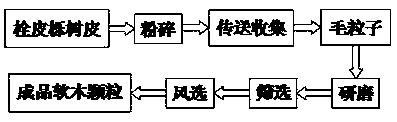

[0027] Such as figure 1 Shown, the processing method of polymer raw material cork particle of the present invention may further comprise the steps:

[0028] S010, crushing

[0029] After the bark is collected from the cork oak, it is generally a roll of 0.5m x 2.5m, and then it is crushed into "hair particles" by a cork crushing device, with a particle size of about 10-15 mm;

[0030] Wherein, the crushing in the above-mentioned step S010 is specifically to first put the cork into the crushing box of the cork crushing device, and rotate the crushing gear of the crushing box to break the cork; Press the cork through the pipeline of the crushing box into the shaker trolley of the cork crushing device, so that the cork passes through the screening of the four-layer screen of the shaker trolley; finally, collect the crushed four kinds of The cork of different specifications enters the distribution bag respectively; since there is a collection port under each layer of screen, fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com