Hollow carbon nanosphere material and preparation method thereof

A technology of nanomaterials and hollow carbon spheres, which is applied in the field of inorganic materials, can solve many time steps and various problems, and achieve the effect of simple and easy preparation method and economical rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

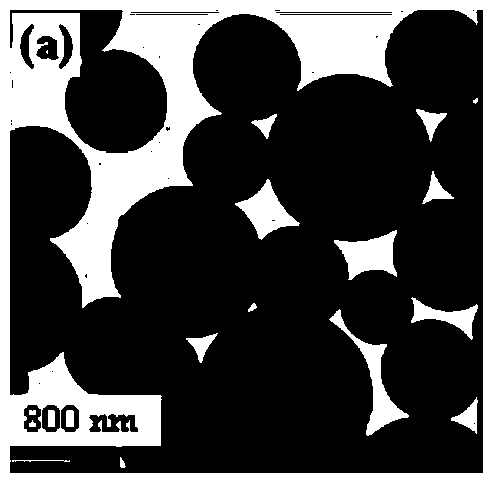

Image

Examples

Embodiment 1

[0036] (1) Synthesis of nano-polystyrene particles

[0037] 2g of poly(N-vinylpyrrolidone) was dissolved in a flask containing 10g of absolute ethanol to obtain solution A, and the flask was placed in a water bath at 70°C and mechanically stirred at a speed of 120rpm; 0.5g of 2,2 '-Azo(isobutyronitrile) was dissolved in 12.5 g of styrene to obtain solution B. After mechanical stirring for 30 minutes, solution B was added dropwise into the flask; 0.25 g of ethylene glycol dimethacrylate was dissolved in a mixed solution of 12.5 g of styrene and 37.5 g of absolute ethanol to obtain solution C. After solution B was added dropwise for 1 hour, solution C was added dropwise to the flask; In the above-mentioned flask; the homogeneous solution of ethylene glycol methacrylate and absolute ethanol was added dropwise and collected after 24 hours to obtain nano-polystyrene particles; in this step, the reaction was kept under mechanical stirring at 70° C. in a water bath.

[0038] (2) Sy...

Embodiment 2

[0044] (1) Synthesis of nano-polystyrene particles

[0045] 1g of poly(N-vinylpyrrolidone) was dissolved in a flask containing 80g of absolute ethanol to obtain solution A, and the flask was placed in a water bath at 40°C and mechanically stirred at a speed of 120rpm; 0.5g of 2,2 '-Azo(isobutyronitrile) was dissolved in 50 g of styrene to obtain solution B. After mechanical stirring for 30 minutes, solution B was added dropwise into the flask; 0.25 g of ethylene glycol dimethacrylate was dissolved in a mixed solution of 50 g of styrene and 50 g of absolute ethanol to obtain solution C. After solution B was added dropwise for 1 hour, solution C was added dropwise to the flask; after solution C was added dropwise for 6 hours, a uniform solution of 1 g ethylene glycol methacrylate and 1 g absolute ethanol was added dropwise to the flask. In the flask; 12 hours after the homogeneous solution of ethylene glycol methacrylate and absolute ethanol was added dropwise, the nano-polysty...

Embodiment 3

[0052] (1) Synthesis of nano-polystyrene particles

[0053] 10g of poly(N-vinylpyrrolidone) was dissolved in a flask containing 5g of absolute ethanol to obtain solution A, and the flask was placed in a water bath at 50°C and mechanically stirred at a speed of 120rpm; 5g of 2,2' - Azo (isobutyronitrile) was dissolved in 50 g of styrene to obtain solution B. After mechanical stirring for 30 minutes, solution B was added dropwise into the flask; 5 g of ethylene glycol dimethacrylate was dissolved in a mixed solution of 10 g of styrene and 10 g of absolute ethanol to obtain solution C. After solution B was added dropwise for 1 hour, solution C was added dropwise to the flask; after solution C was added dropwise for 6 hours, a uniform solution of 10 g ethylene glycol methacrylate and 10 g absolute ethanol was added dropwise to the In the flask; 24 hours after the homogeneous solution of ethylene glycol methacrylate and absolute ethanol was added dropwise, the nano-polystyrene par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com