A kind of method of preparing pyromellitic anhydride from methanol to gasoline synthetic oil

A technology for producing gasoline from pyromellitic anhydride and methanol, which is applied in organic chemistry and other fields, and can solve problems such as complicated process flow and difficult separation of durene and partial tetramethylbenzene, and achieve simplified purification process, simplified preparation and purification process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

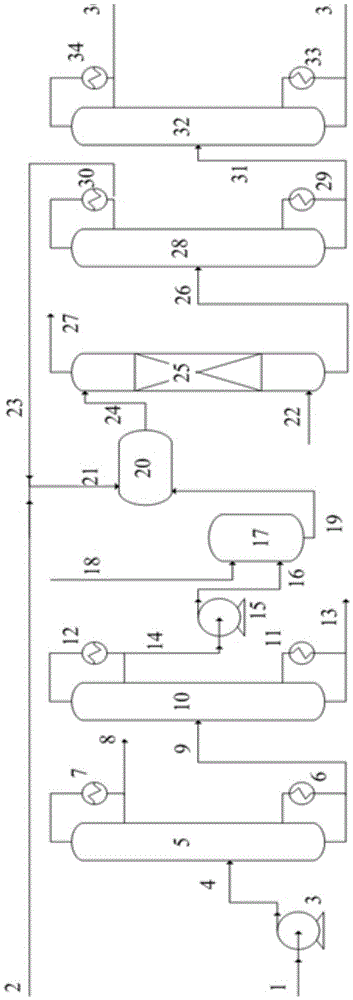

[0037] As attached figure 1 As shown, the material 1 with a flow rate of 1000kg / h has a mesitylene and tetramethylbenzene content of 45wt% and 7.5wt%, respectively. 10 + The heavy aromatics feed pump 3 enters the light removal tower 5 at the 50th theoretical plate. The tower has a total of 80 theoretical plates, the reflux ratio is 12, the top operating pressure is 10kPa, the top and bottom temperatures are 120.7℃ and 140.7℃, respectively, the flow rate of the material 8 extracted from the top is 370kg / h, the bottom The content of mesitylene in the extracted material 9 was 68.9 wt%.

[0038] The material 9 from the light removal tower enters the weight removal tower 10 at the 40th theoretical plate. The tower has a total of 60 theoretical plates, the reflux ratio is 20, the top operating pressure is 10kPa, and the top and bottom temperatures are 138 respectively ℃ and 149.6℃. The flow rate of the material 14 extracted at the top of the tower is 495 kg / h, in which the contents o...

Embodiment 2

[0043] As attached figure 1 As shown, the material 1 with a flow rate of 1000kg / h has a mesitylene and tetramethylbenzene content of 51wt% and 6wt%, respectively. 10 + The heavy aromatics feed pump 3 enters the light removal tower 5 at the 43rd theoretical plate. The tower has 67 theoretical plates, the reflux ratio is 10.5, the top operating pressure is 30kPa, and the top and bottom operating temperatures are 125.9°C and 145.6°C, respectively. The material 8 with a flow rate of 350 kg / h is extracted from the top of the tower, and the content of mesitylene in the material 9 extracted from the tower is 78.0 wt%.

[0044] The material 9 from the light-removing tower enters the weight-removing tower 10 at the 36th theoretical plate. The tower has 51 total theoretical plates, the reflux ratio is 17, the top operating pressure is 30kPa, and the top and bottom operating temperature They are 145.4°C and 156.6°C, respectively. The material 14 with a flow rate of 560 kg / h is extracted f...

Embodiment 3

[0049] As attached figure 1 As shown, the material 1 with a flow rate of 1000kg / h has a content of mesitylene and tetramethylbenzene of 55.5wt% and 5.6wt%, respectively. 10 + The heavy aromatics feed pump 3 enters the light removal tower 5 at the 40th theoretical plate. The tower has a total of 60 theoretical plates, the reflux ratio is 7, the operating pressure at the top of the tower is 50kPa, and the operating temperatures at the top and bottom of the tower are 130.7°C and 151.7°C. The flow rate of the material 8 extracted from the top of the tower is 330 kg / h, and the content of mesitylene in the material 9 extracted from the tower bottom is 79.5 wt%.

[0050] The material 9 from the light removal tower enters the weight removal tower 10 at the 34th theoretical plate. The tower has 45 theoretical plates, the reflux ratio is 15, the top operating pressure is 50kPa, and the top and bottom operating temperatures are respectively 150.4°C and 161.6°C. The flow rate of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com