Multi-block copolymer

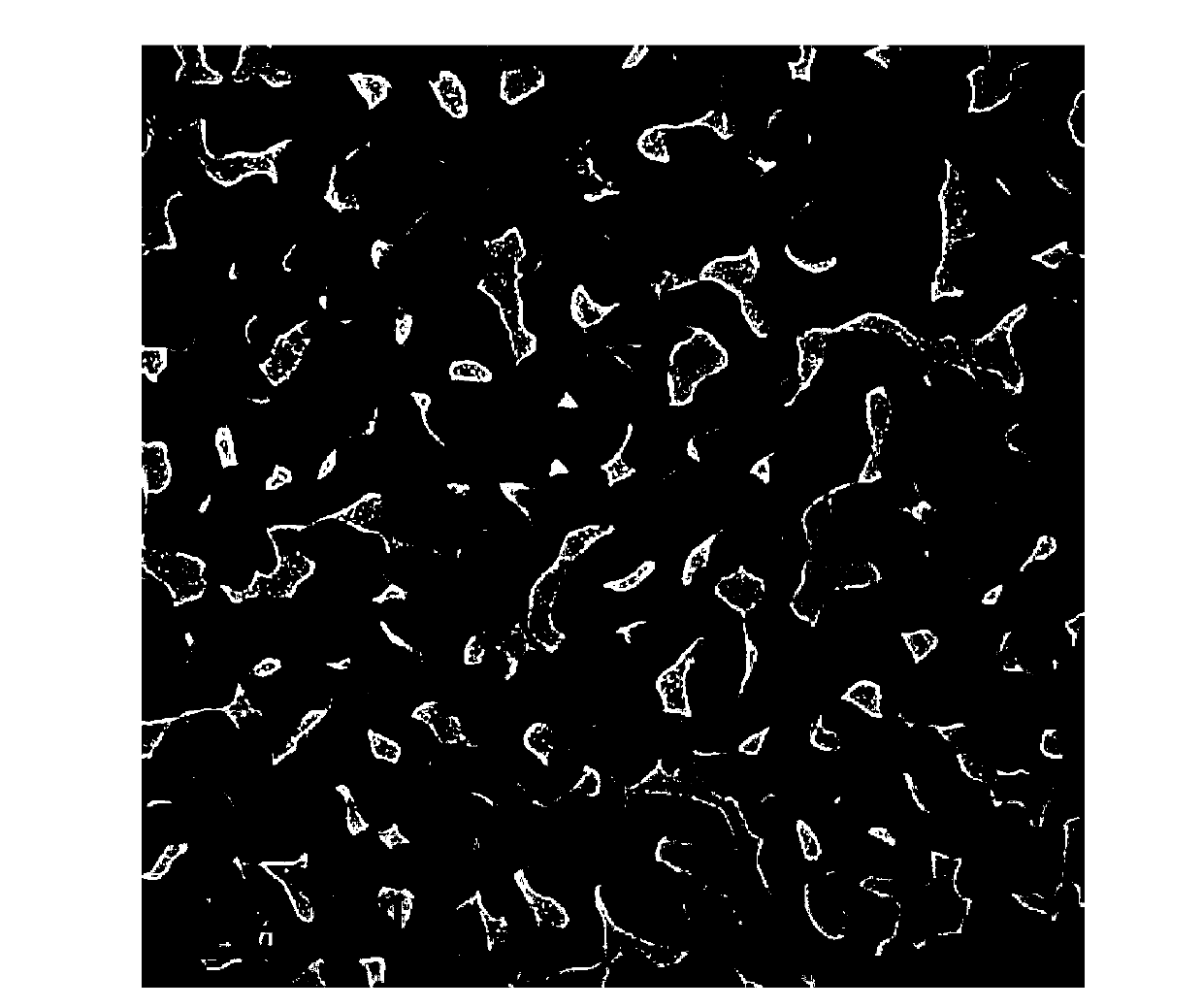

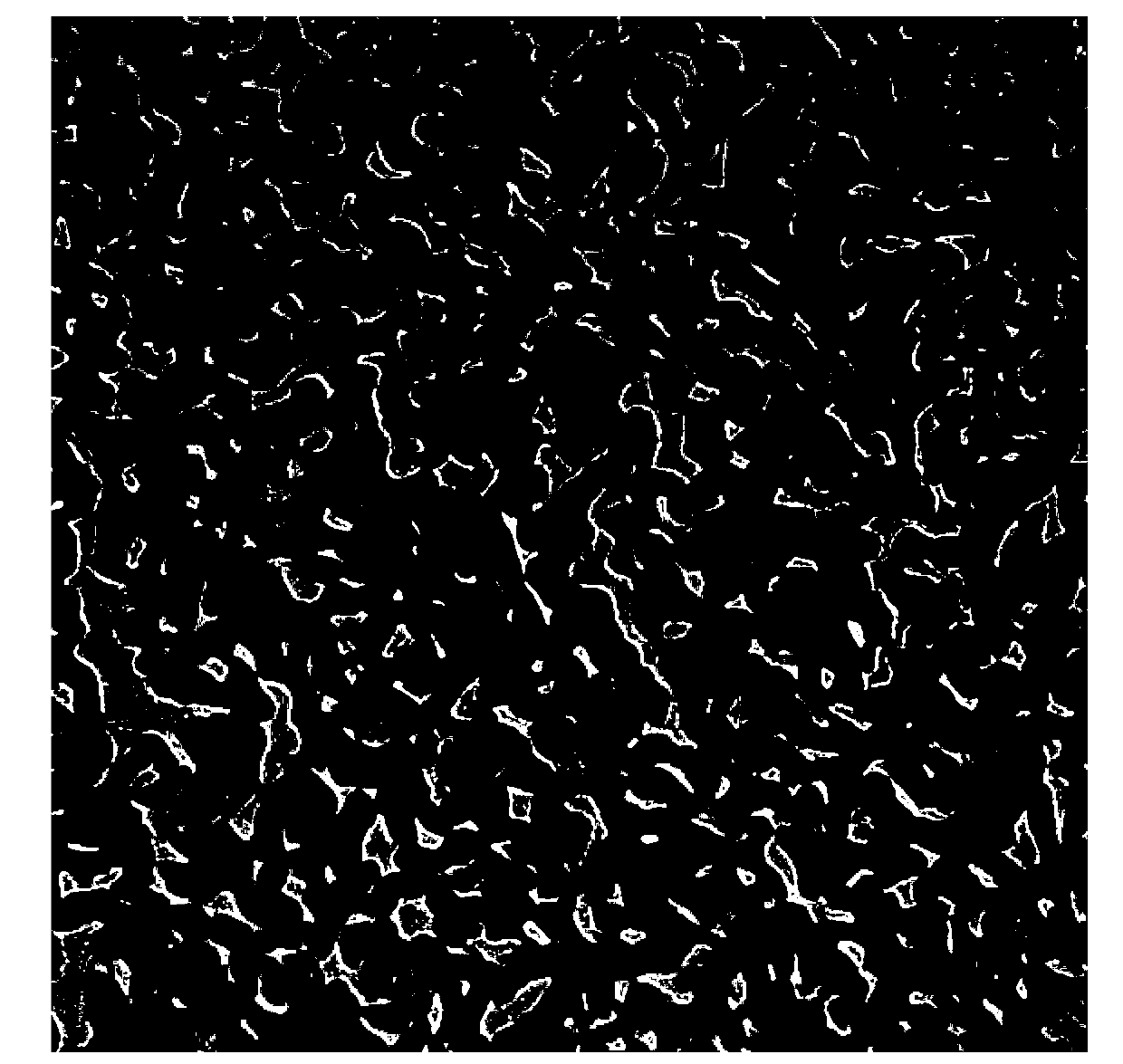

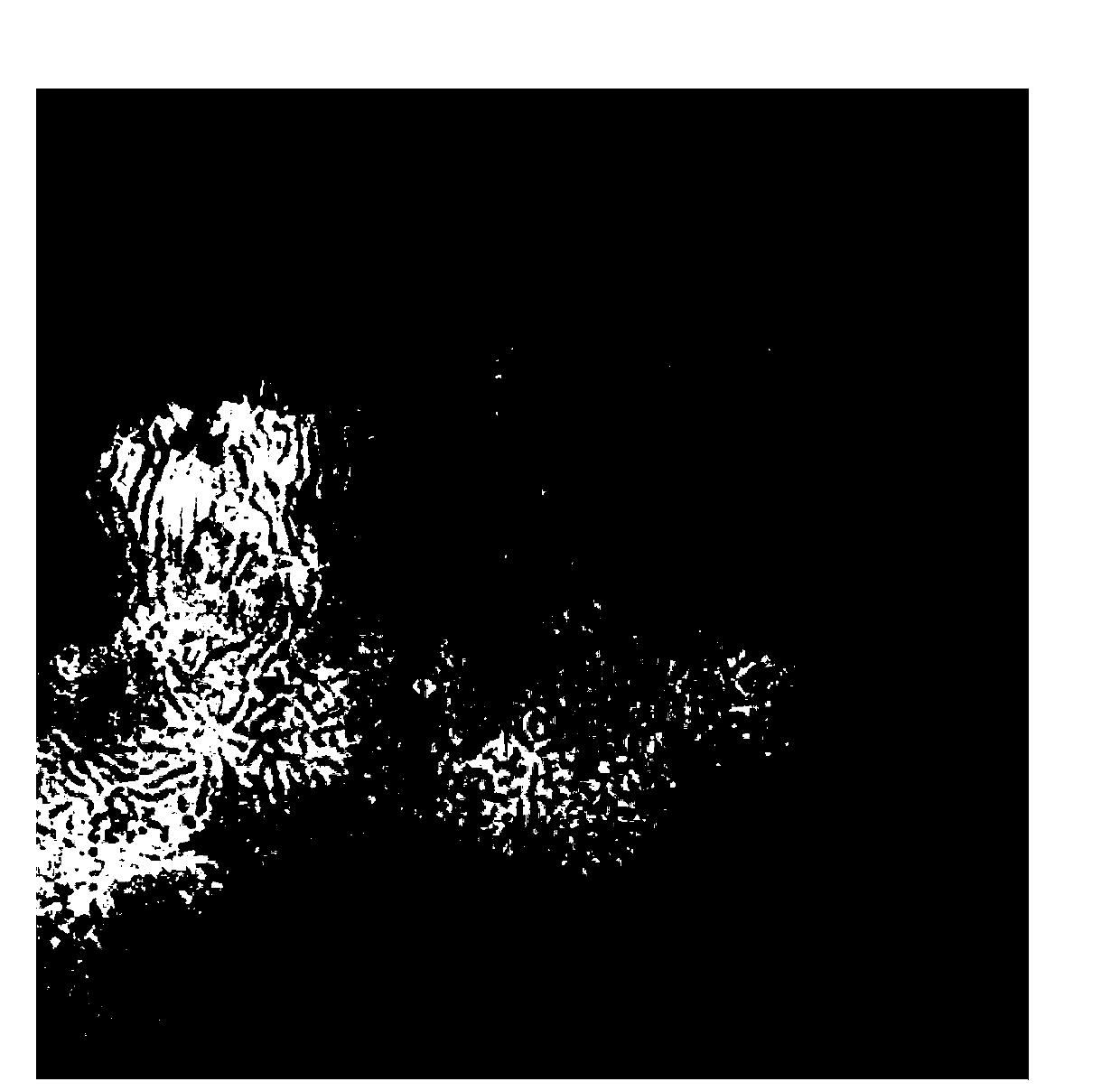

A multi-block copolymer and segment technology, applied in the field of polymer materials, can solve the problems of no obvious improvement in performance, incomplete elimination of polyoxyethylene crystallinity, and incomplete elimination of triblock copolymer crystallinity. , to achieve the effect of broadening the hydrophilicity and mechanical properties and achieving the best comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064]

[0065] (1) Synthesis of block chain A

[0066] Under a nitrogen atmosphere, 15.5 g (15.8 mmol) of methoxypolyoxyethylene monomethacrylate monomer (PEGMA-1, M n =980, m=20) was dissolved in 15ml of toluene, and 45.3mg (0.316mmol) of cuprous bromide and 98.65mg (0.732mmol) of 4,4'-bipyridine were added to the solution. After stirring well for 10 minutes, 57.2 mg (0.316 mmol) of ethyl α-bromopropionate was added, and the temperature was raised to 90°C to start polymerization. After 30 hours of polymerization, the reaction system was placed in ice water to stop the polymerization reaction. Add tetrahydrofuran for dilution, remove the catalyst / ligand complex with a neutral alumina column, spin dry, and then wash away unreacted monomers with anhydrous ether to obtain refined polymethoxyethylene glycol monomethacrylic acid Esters (referred to as P(PEGMA)-1). The number average molecular weight of P(PEGMA)-1 is 42000, the GPC curve shows a single peak distribution, and t...

Embodiment 2

[0079]

[0080] With embodiment 1 gained polymethoxypolyoxyethylene monomethyl polyacrylate-b-polystyrene-b-polymethoxypolyoxyethylene monomethyl polyacrylate-b-polystyrene (A-B-A-B type) The tetrablock copolymer is used as the macroinitiator to prepare the pentablock copolymer.

[0081] (1) Synthesis of A-B-A-B-A Pentablock Copolymer

[0082] Under an argon atmosphere, add 10.92 mg (0.075 mmol) of cuprous bromide, 23.77 mg (0.15 mmol) of 4,4'-bipyridine and 5.2 ml of toluene, stir for 10 minutes to form a catalyst / ligand complex and then add 3.13 g (3.0 mmol) methoxypolyoxyethylene monomethacrylate monomer (PEGMA-1, M n =1042, m=20), continue stirring for 15 minutes and then add 2.4g (0.015mmol) of macroinitiator (tetrablock copolymer). Seal the reaction system and stir it magnetically. After the macromolecular initiator is dissolved, the temperature of the reaction system is raised to 90° C. at a rate of 1.5° C. / min to start polymerization. After 100 hours of polymeriza...

Embodiment 3

[0089]

[0090] (1) Synthesis of block chain A

[0091] Under a nitrogen atmosphere, 18.0 g (40.0 mmol) of methoxypolyoxyethylene monomethacrylate monomer (PEGMA-2, M n =450, m=8) was dissolved in 25ml of toluene, and 57.34mg (0.40mmol) of cuprous bromide and 107.82mg (0.80mmol) of 4,4'-bipyridine were added to the solution. After fully stirring for 10 minutes, 75.57 mg (0.40 mmol) of dichloroacetophenone was added, and the temperature was raised to 90°C to start polymerization. After 25 hours of polymerization, the reaction system was placed in ice water to stop the polymerization reaction. Add tetrahydrofuran for dilution, remove the catalyst / ligand complex with a neutral alumina column, spin dry, and then wash away unreacted monomers with anhydrous ether to obtain refined polymethoxyethylene glycol monomethacrylic acid Esters (referred to as P(PEGMA)-2). The number average molecular weight of P(PEGMA)-2 is 6000, the GPC curve shows a single peak distribution, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com