Preparation of cupric oxide doped with titanium dioxide gradient film

A technology of titanium dioxide and copper oxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of harsh preparation process requirements, lower photoelectric conversion efficiency, and limit solar energy utilization, so as to achieve unique technology, improve photoelectrochemical stability, Realize the effect of photoelectric characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

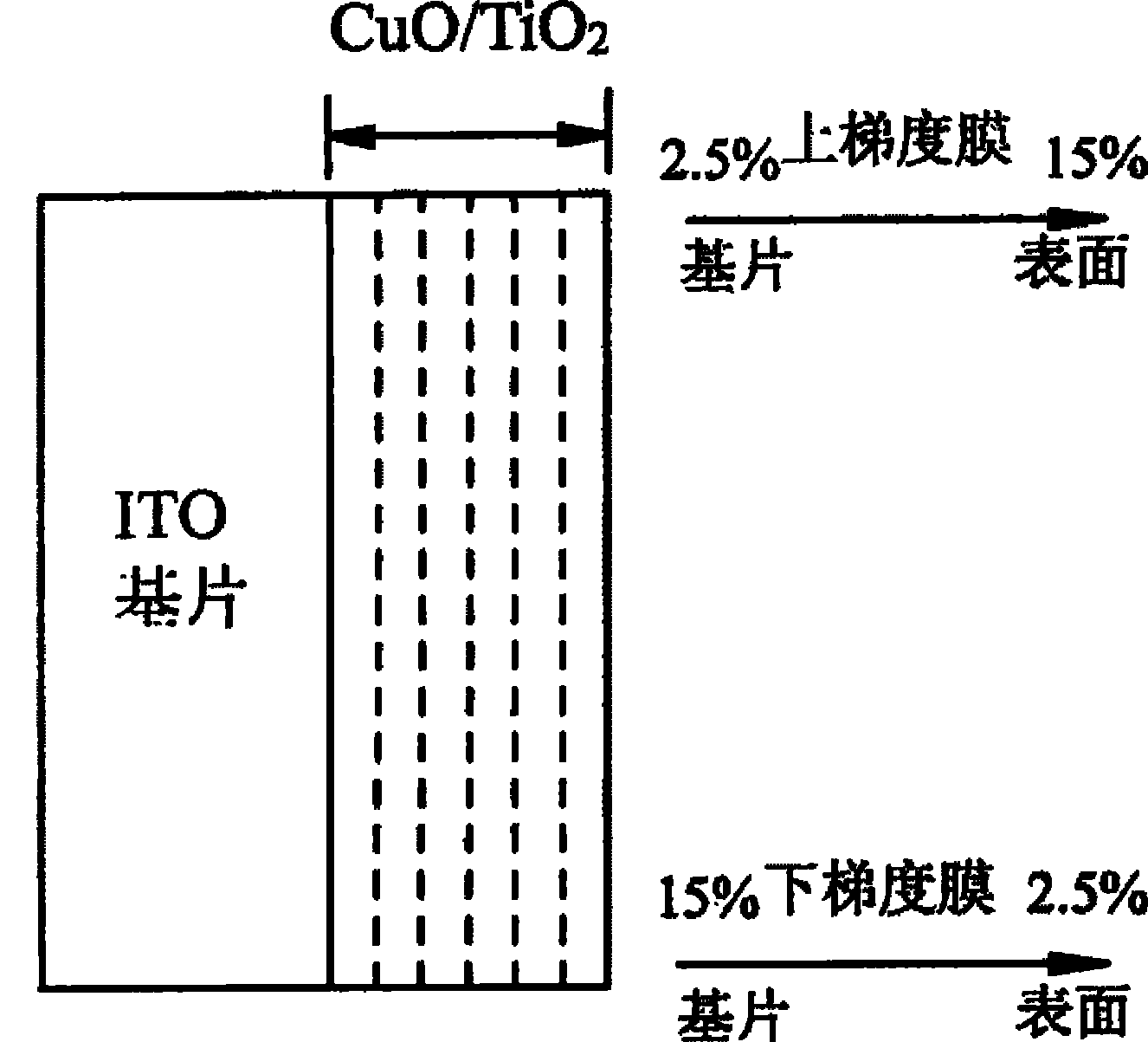

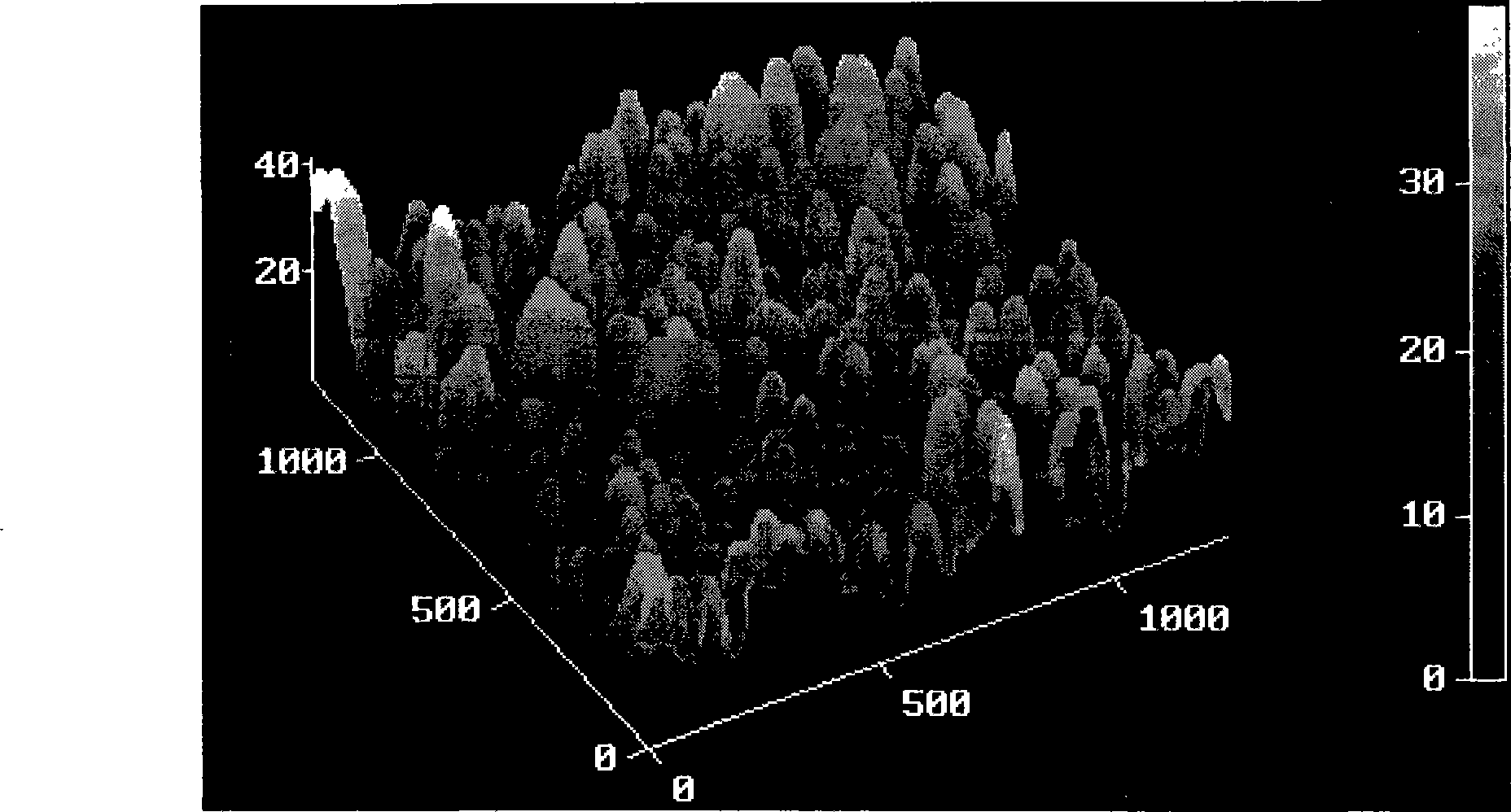

[0020] Preparation of gradient thin films on copper oxide doped titania. The specific preparation process is as follows: dissolve 17ml of butyl titanate in 68ml of absolute ethanol, then add 4.8ml of diethanolamine, and stir on a constant temperature magnetic stirrer at room temperature for 30min to obtain solution A; take 0.213g of chlorinated Dissolve copper in 20ml of absolute ethanol, add solution A, stir magnetically for 60min to obtain solution B; then add solution B mixed solution of deionized water 0.9ml and absolute ethanol 9ml, stir magnetically for 60min to obtain a Cu / Ti molar ratio of 2.5% of Sol. According to the same experimental conditions, sols with Cu / Ti molar ratios of 5%, 7.5%, 10%, 12.5% and 15% were synthesized respectively. In order to obtain a clean substrate, the substrate was soaked in potassium dichromate lotion for 10 hours, then ultrasonically washed with absolute ethanol for 15 minutes and rinsed with deionized water, and dried at 80°C for late...

Embodiment 2

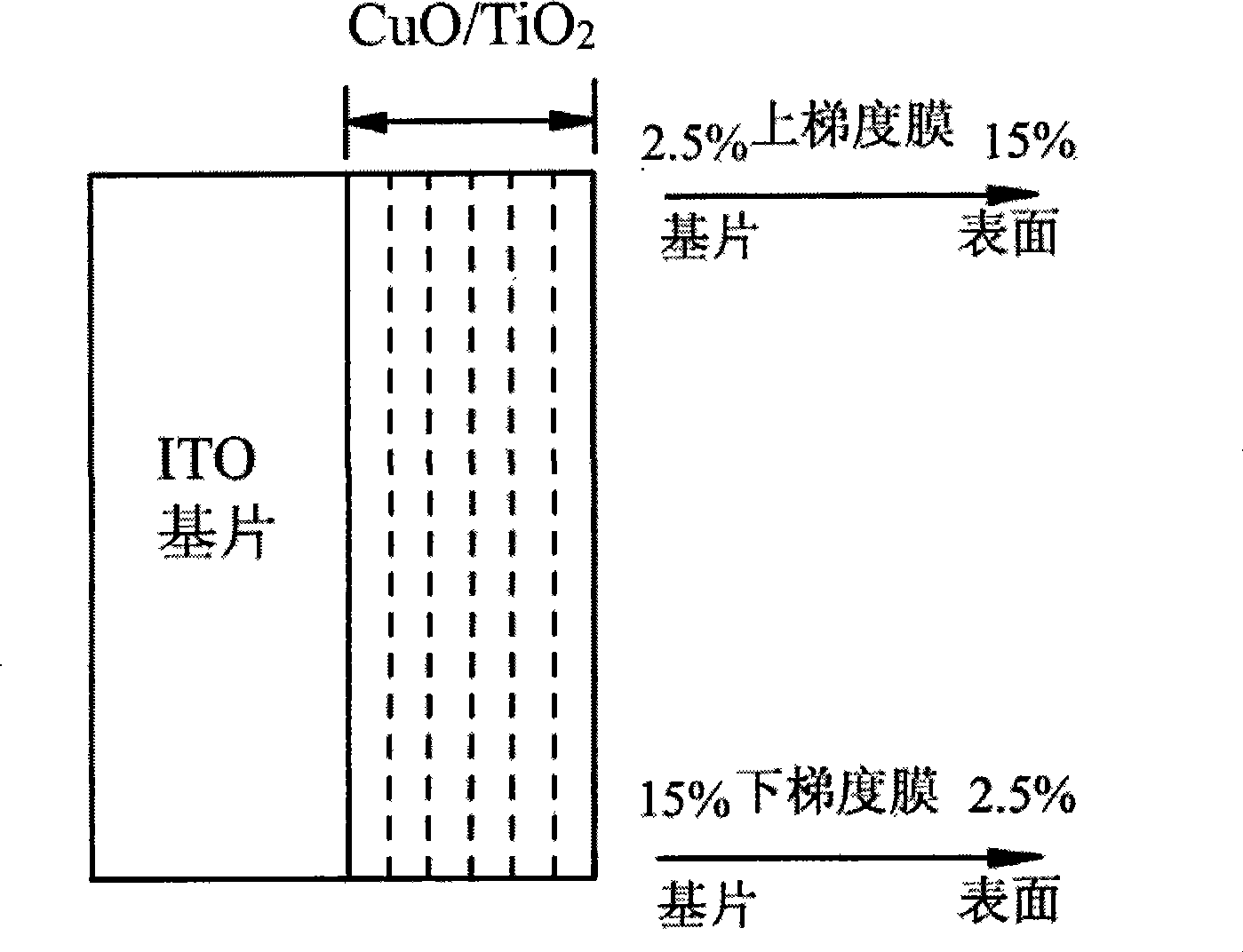

[0022]Preparation of gradient thin films on copper oxide doped titania. The specific preparation process is as follows: dissolve 17ml of butyl titanate in 68ml of absolute ethanol, then add 4.8ml of diethanolamine, and stir on a constant temperature magnetic stirrer at room temperature for 30min to obtain solution A; take 0.425g of chlorinated Dissolve copper in 20ml of absolute ethanol, add solution A, stir magnetically for 60min to obtain solution B; then add solution B mixed solution of deionized water 0.9ml and absolute ethanol 9ml, stir magnetically for 60min to obtain 5% Cu / Ti molar ratio of Sol. According to the same experimental conditions, sols with Cu / Ti molar ratios of 0, 1%, 2%, 3% and 4% were synthesized respectively. In order to obtain a clean substrate, the substrate was soaked in potassium dichromate lotion for 10 hours, then ultrasonically washed with absolute ethanol for 15 minutes and rinsed with deionized water, and dried at 80°C for later use. Utilize ab...

Embodiment 3

[0024] Preparation of Gradient Thin Films Under Copper Oxide Doping TiO2. The specific preparation process is as follows: dissolve 17ml of butyl titanate in 68ml of absolute ethanol, then add 4.8ml of diethanolamine, and stir on a constant temperature magnetic stirrer at room temperature for 30min to obtain solution A; take 0.213g of chlorinated Dissolve copper in 20ml of absolute ethanol, add solution A, stir magnetically for 60min to obtain solution B; then add solution B mixed solution of deionized water 0.9ml and absolute ethanol 9ml, stir magnetically for 60min to obtain a Cu / Ti molar ratio of 2.5% of Sol. According to the same experimental conditions, sols with Cu / Ti molar ratios of 5%, 7.5%, 10%, 12.5% and 15% were synthesized respectively. In order to obtain a clean substrate, the substrate was soaked in potassium dichromate lotion for 10 hours, then ultrasonically washed with absolute ethanol for 15 minutes and rinsed with deionized water, and dried at 80°C for lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com