Process for producing codope titanium dioxide thin film of nitrogen and bismuth

A titanium dioxide, co-doping technology, applied in chemical instruments and methods, chemical/physical processes, devices for coating liquids on surfaces, etc. and other problems, to achieve the effect of easy adjustment, unique process, and easy control of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

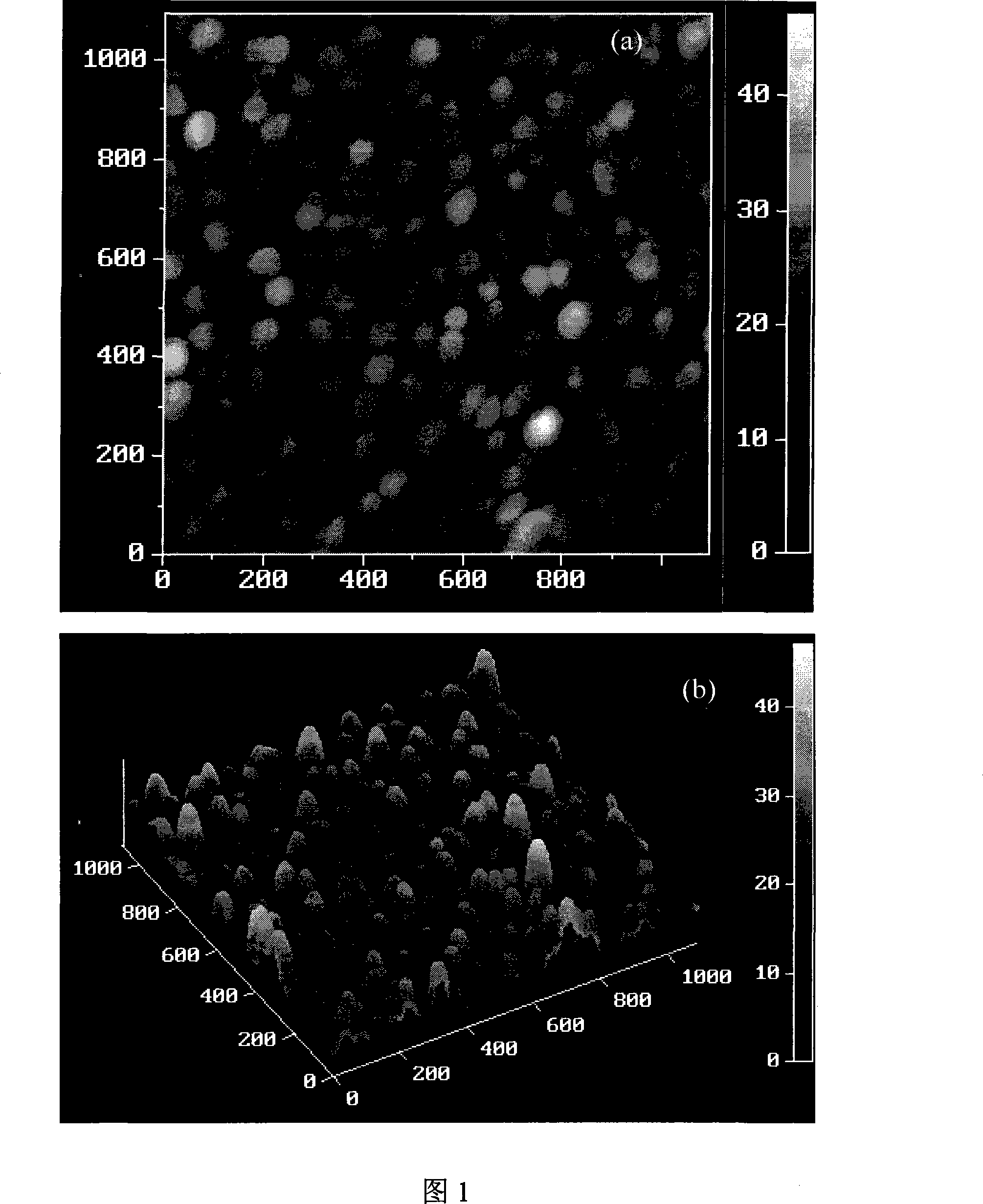

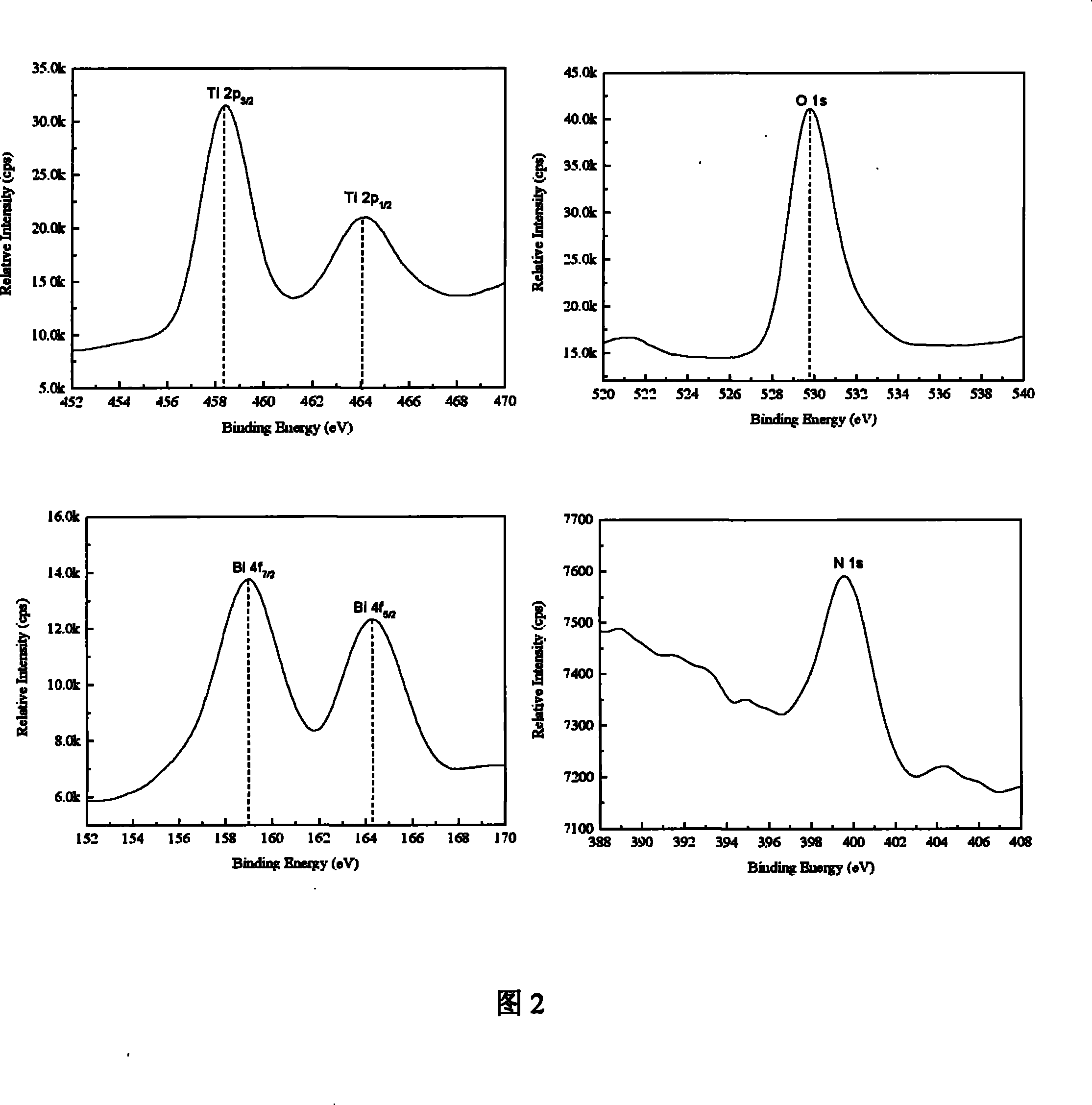

[0027] 0.5%N-0.5%Bi / TiO 2 Film preparation. The specific preparation process is as follows: dissolve 17ml of butyl titanate in 68ml of absolute ethanol, then add 4.8ml of diethanolamine, and stir on a constant temperature magnetic stirrer at room temperature for 30min to obtain solution A; take 0.009g of fluorinated Dissolve ammonium in 10ml of absolute ethanol, add solution A, and stir magnetically for 60 minutes to obtain solution B; take 0.122g of bismuth nitrate and 20ml of absolute ethanol, and add an appropriate amount of dilute nitric acid at the same time to promote the dissolution of bismuth nitrate in absolute ethanol and drop Add to solution B, stir magnetically for 60min to obtain solution C, then add a mixed solution of 0.9ml deionized water and 9ml absolute ethanol, stir magnetically for 60min to obtain nitrogen and bismuth co-doped TiO 2 Sol. In order to obtain a clean substrate, soak the substrate in potassium dichromate lotion for 10 hours, then ultrasonical...

Embodiment 2

[0029] 5%N-5%Bi / TiO 2 Film preparation. The specific preparation process is as follows: dissolve 17ml of butyl titanate in 68ml of absolute ethanol, then add 4.8ml of diethanolamine, and stir on a constant temperature magnetic stirrer at room temperature for 30min to obtain solution A; take 0.2ml of ammonia water to dissolve Add solution A to 10ml of absolute ethanol, stir magnetically for 60min to obtain solution B; take 1.126g of bismuth nitrate and 20ml of absolute ethanol, and add an appropriate amount of dilute nitric acid at the same time to promote the dissolution of bismuth nitrate in absolute ethanol and add dropwise to In solution B, stir magnetically for 60 minutes to obtain solution C, then add a mixed solution of 0.9ml of deionized water and 9ml of absolute ethanol, and stir magnetically for 60min to obtain nitrogen and bismuth co-doped TiO 2 Sol. In order to obtain a clean substrate, soak the substrate in potassium dichromate lotion for 10 hours, then ultrasoni...

Embodiment 3

[0031] 2%N-8%Bi / TiO 2 Film preparation. The specific preparation process is as follows: dissolve 17ml of butyl titanate in 68ml of absolute ethanol, then add 4.8ml of diethanolamine, and stir on a constant temperature magnetic stirrer at room temperature for 30min to obtain solution A; take 0.08ml of ammonia water to dissolve Add solution A to 10ml of absolute ethanol, stir magnetically for 60 minutes to obtain solution B; take 1.26g of bismuth chloride and 20ml of absolute ethanol, and add an appropriate amount of dilute hydrochloric acid at the same time to promote the dissolution of bismuth chloride in absolute ethanol and drop Add to solution B, stir magnetically for 60min to obtain solution C, then add a mixed solution of 0.9ml of deionized water and 9ml of absolute ethanol, stir magnetically for 60min to obtain nitrogen and bismuth co-doped TiO 2 Sol. In order to obtain a clean substrate, soak the substrate in potassium dichromate lotion for 10 hours, then ultrasonical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com