Polysulfone engineering plastic production method and equipment

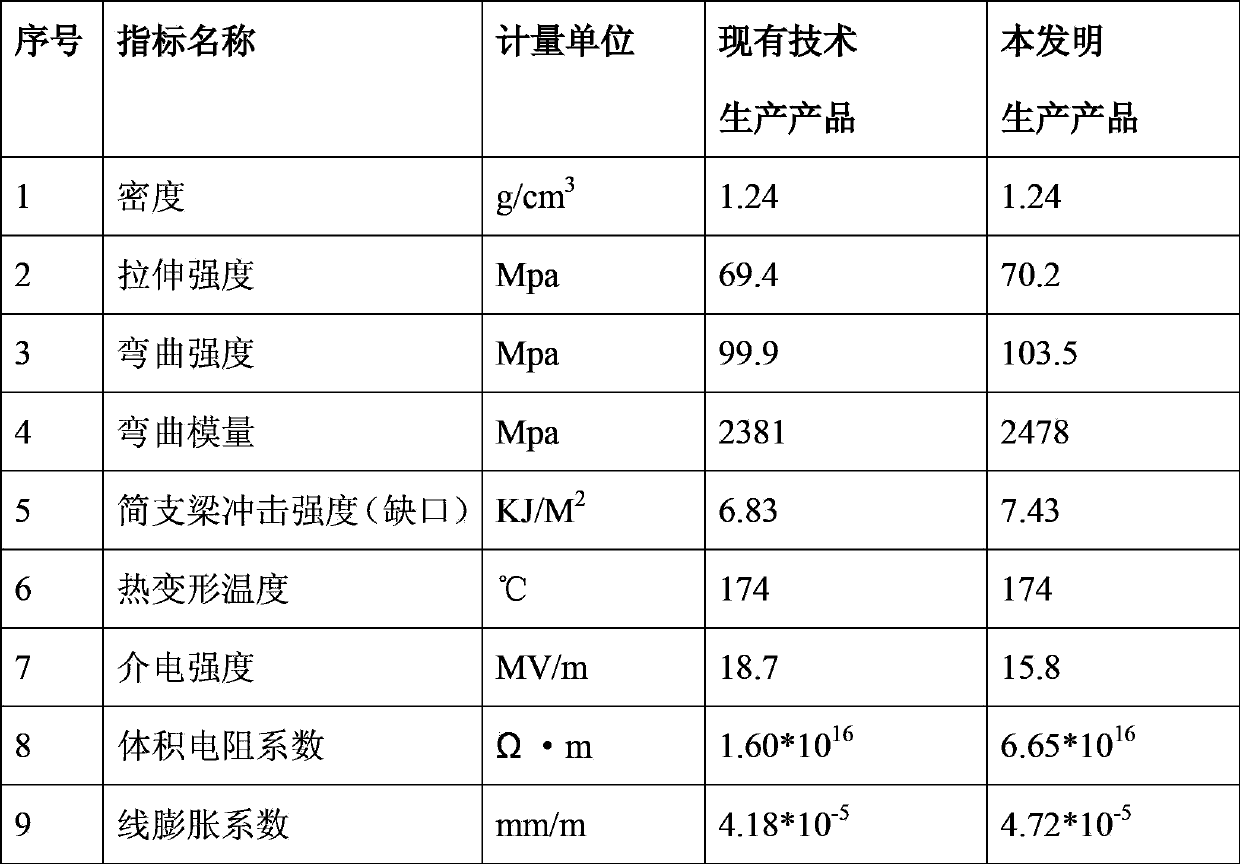

A technology for engineering plastics and production methods, which is applied in the field of preparation and processing of organic polymer compounds, can solve the problems of high humidity of materials, prolonged drying time, easy overflow of fine powder, etc., and achieves overall cost reduction, high drying efficiency, and health threats. and the effects of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes in detail a method and equipment for producing polysulfone engineering plastics according to a specific embodiment of the present invention with reference to the accompanying drawings. However, it should be understood that the present invention is not limited to such an embodiment described below, and the technical idea of the present invention may be implemented in combination with other known technologies or other technologies having the same functions as those known technologies.

[0021] In the following description, in order to clearly show the structure and working mode of the present invention, many directional words will be used for description, but "front", "rear", "left", "right", "outer", "inner" should be "," "outward", "inward", "up", "down" and other words are to be understood as convenient terms, and should not be understood as limiting words.

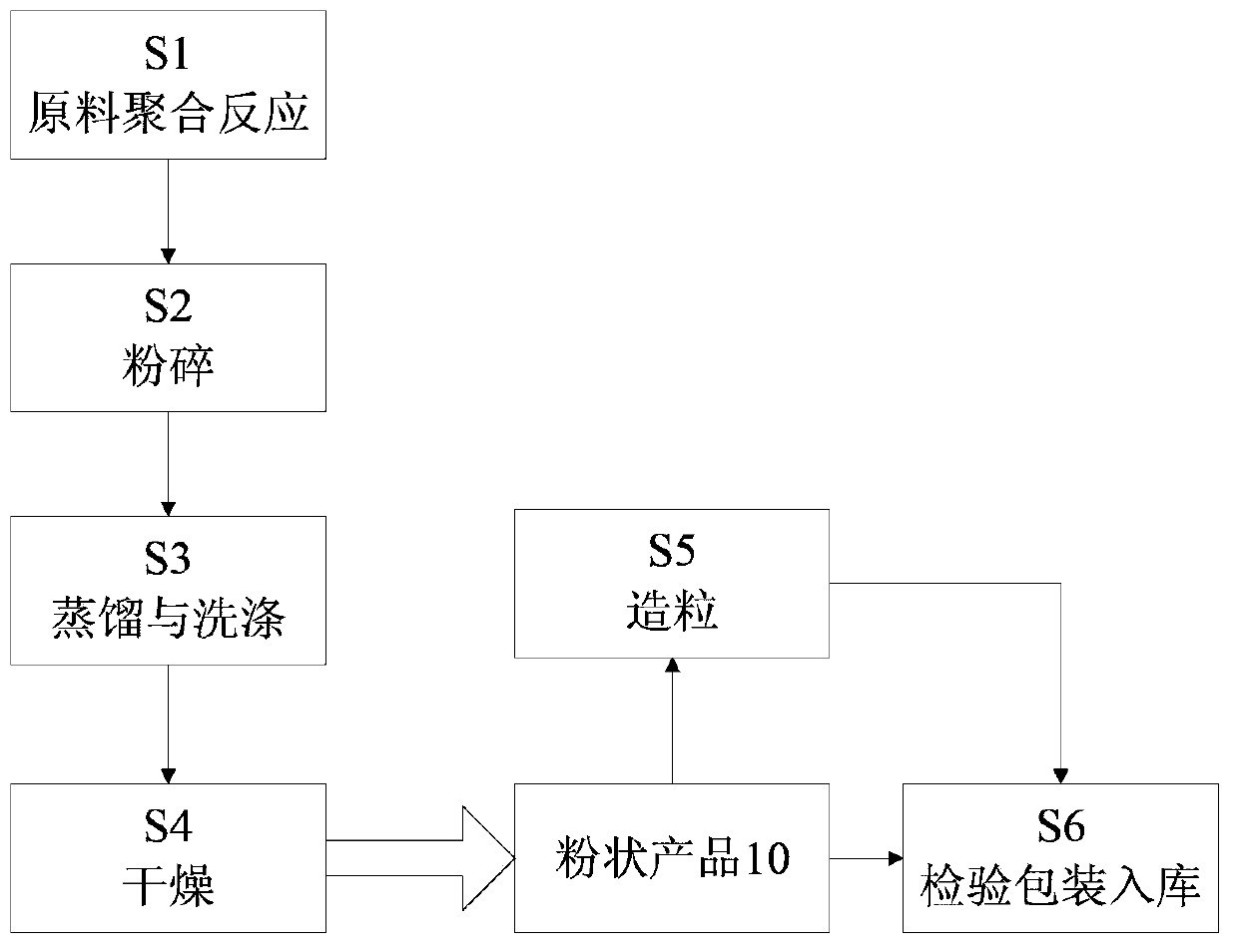

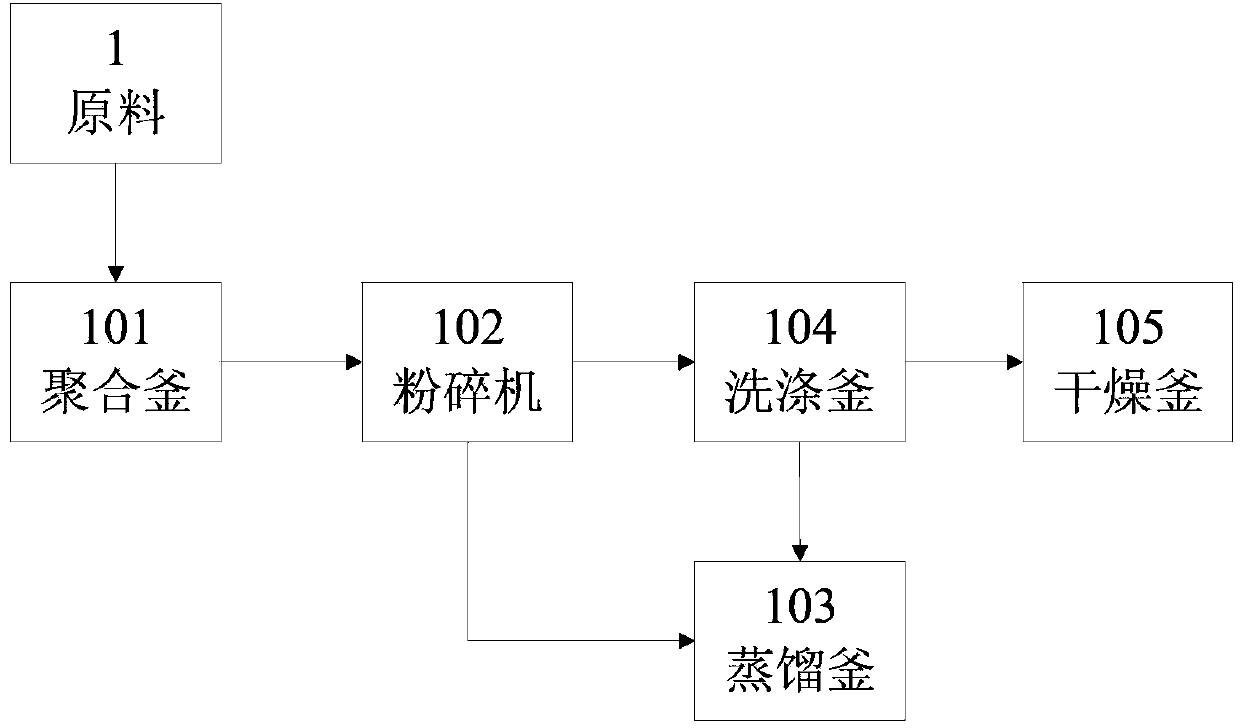

[0022] like figure 1 As shown in, the technical solution provided by the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com