A scale inhibitor for inhibiting scaling of flue gas turbine blades

A technology of flue gas turbine and scale inhibitor, which can be used in the fields of processing equipment corrosion/fouling inhibition, hydrocarbon oil processing, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

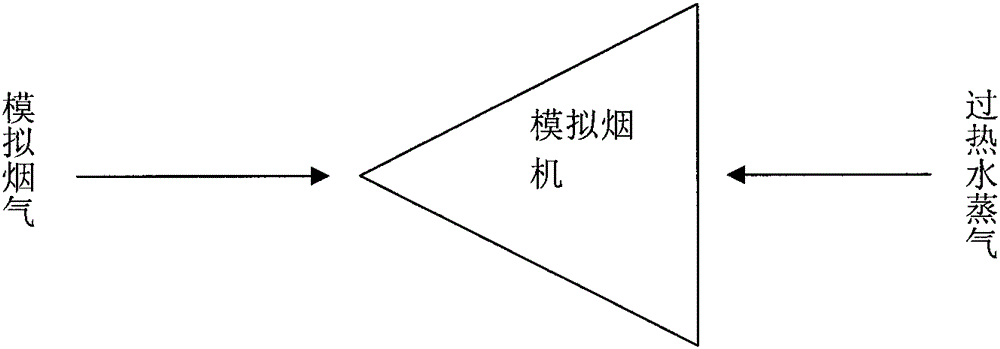

Image

Examples

Embodiment 1

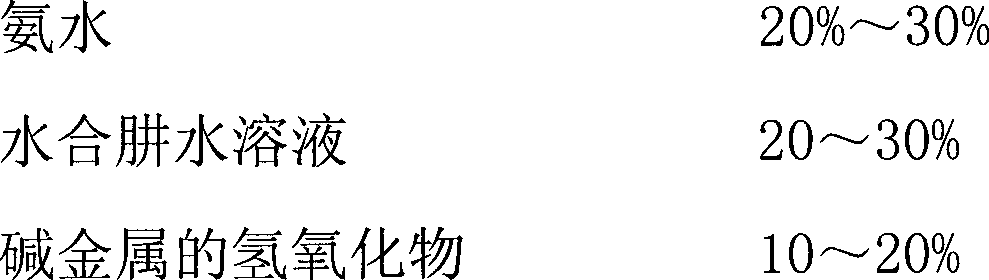

[0018] Antiscalant of the present invention is made up of following component and content:

[0019]

[0020] At normal temperature and pressure, dissolve the above-mentioned sodium hydroxide in the above-mentioned deionized water. After the dissolution is complete, add the above-mentioned ammonia water and hydrazine hydrate aqueous solution in proportion, and stir evenly to obtain the scale inhibitor of the present invention.

Embodiment 2

[0022] Antiscalant of the present invention is made up of following component and content:

[0023]

[0024] At normal temperature and pressure, dissolve the above-mentioned sodium hydroxide in the above-mentioned deionized water. After the dissolution is complete, add the above-mentioned ammonia water and hydrazine hydrate aqueous solution in proportion, and stir evenly to obtain the scale inhibitor of the present invention.

Embodiment 3

[0026] Antiscalant of the present invention is made up of following component and content:

[0027]

[0028] At normal temperature and pressure, dissolve the above-mentioned sodium hydroxide in the above-mentioned deionized water. After the dissolution is complete, add the above-mentioned ammonia water and hydrazine hydrate aqueous solution in proportion, and stir evenly to obtain the scale inhibitor of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com