Flexible cable for port

A flexible cable and port technology, applied in the direction of insulated cables, bendable cables, cables, etc., to achieve the effects of less smoke, low pH and conductivity, and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

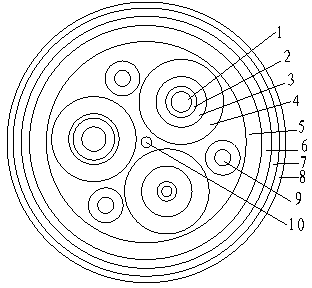

[0014] A flexible cable for ports, including a conductor 1, an insulating layer 2 and a sheath layer, the conductor 1 is twisted from several tinned copper guide wires, and the conductor 1 is wrapped with flame-retardant ethylene-propylene rubber Insulation layer 2, the insulation layer 2 is wrapped with nylon shielding layer 3 and tinned copper wire shielding 4 layers respectively to form a wire core, and the three wire cores are twisted and wrapped with low-smoke, halogen-free and oxygen-isolated tapes A tape layer 5, a flame-retardant glass fiber rope is provided between the core and the tape layer as a filling layer; the tape layer 5 is also provided with a nylon shielding layer II6 and a tinned copper wire shielding layer II7, the tinned copper wire shielding layer 7 is wrapped with a sheath layer 8 made of high flame-retardant, low-smoke, halogen-free, corrosion-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com