Permanent magnet synchronous motor torque control method based on sliding mode flux linkage observer

A permanent magnet synchronous motor, flux linkage observer technology, applied in observer control, single motor speed/torque control, torque ripple control, etc., can solve the problem of stator flux linkage estimation accuracy drop, torque and flux linkage ripple It can eliminate the problems of large motor power factor and reduce the power factor of the motor, so as to achieve the effect of eliminating the position sensor, reducing the torque and flux pulsation, and reducing the motor loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

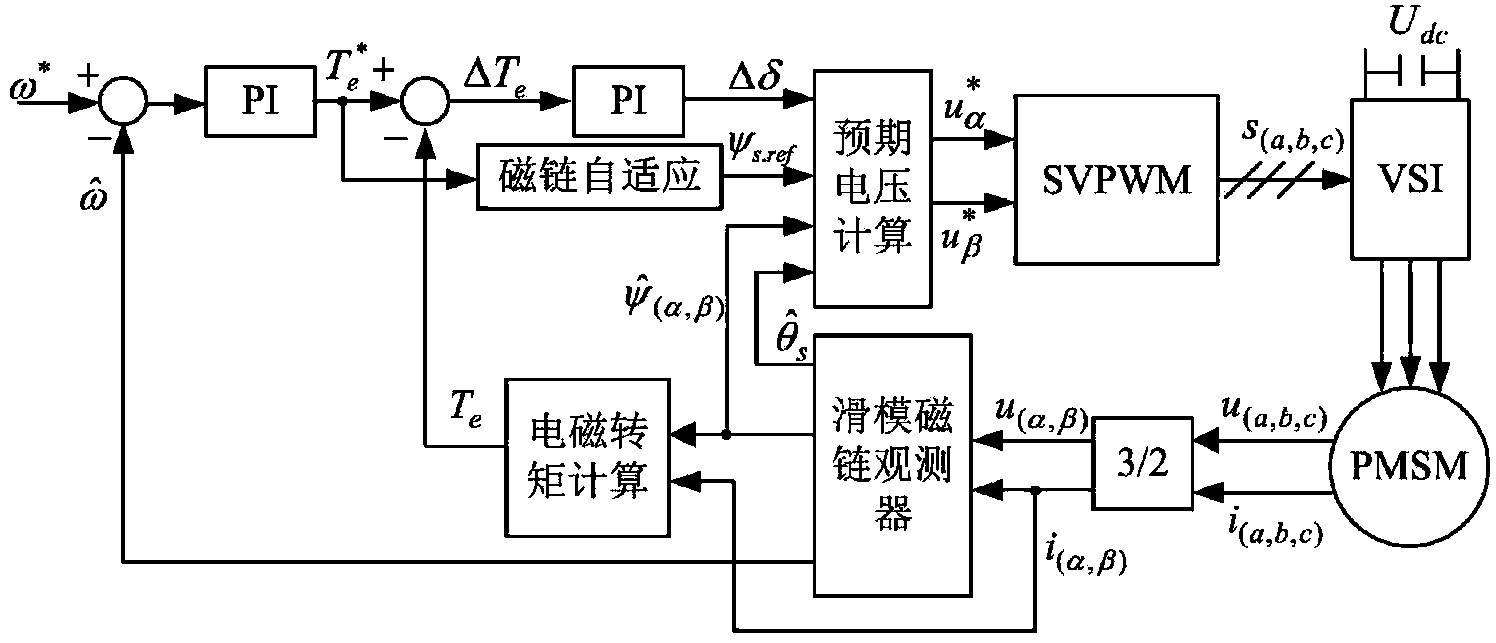

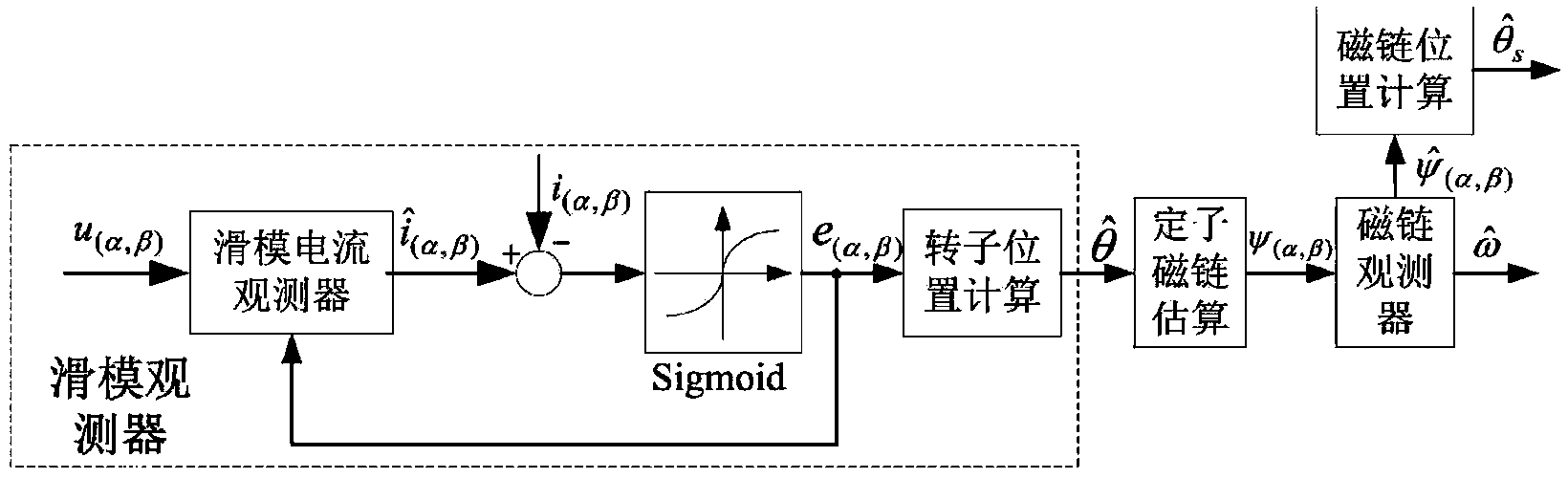

[0027] Combine below figure 1 , figure 2 The technical scheme of the present invention is described in further detail.

[0028] Such as figure 1 As shown, the permanent magnet synchronous motor torque control system based on the sliding mode flux observer in the present invention includes a permanent magnet synchronous motor, 3 / 2 coordinate transformation, sliding mode flux observer, electromagnetic torque calculation, speed PI regulator, Torque PI regulator, flux linkage adaptation, expected voltage calculation, SVPWM module and inverter.

[0029] The specific implementation steps of the permanent magnet synchronous motor torque control method based on the sliding mode flux observer in the present invention are as follows:

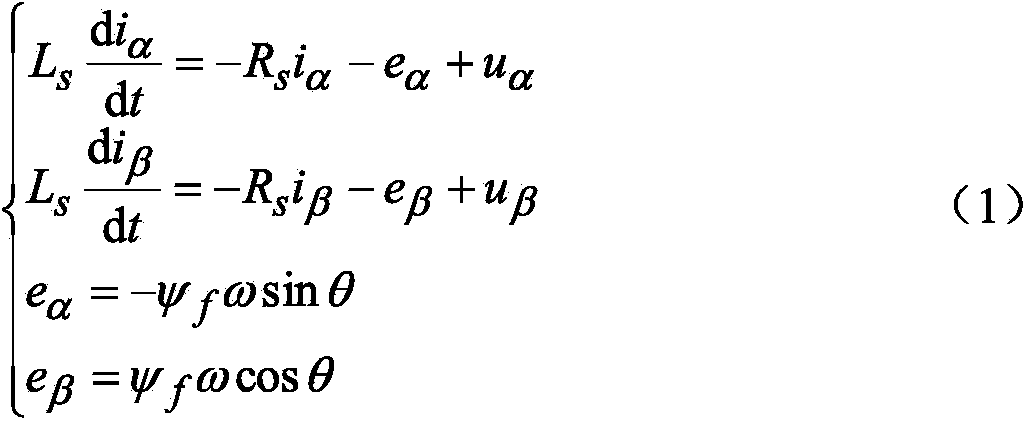

[0030] Step 1), detect the three-phase current i of the permanent magnet synchronous motor a i b i c and three-phase voltage u a , u b , u c , after the 3 / 2 coordinate transformation, the current component i in the two-phase static AC coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com