Device and method for detecting defects on surface of solar cell

A solar cell and defect detection technology, applied in the energy field, can solve problems affecting the correctness of results, unstable work, short working life, etc., and achieve the effects of improved detection efficiency and accuracy, simple operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

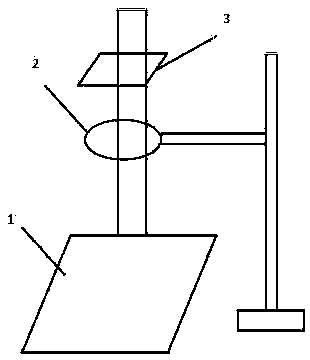

[0035] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

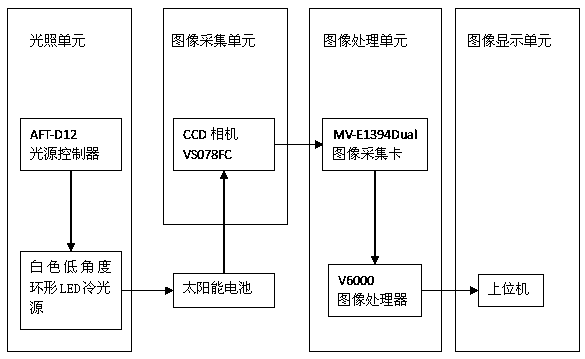

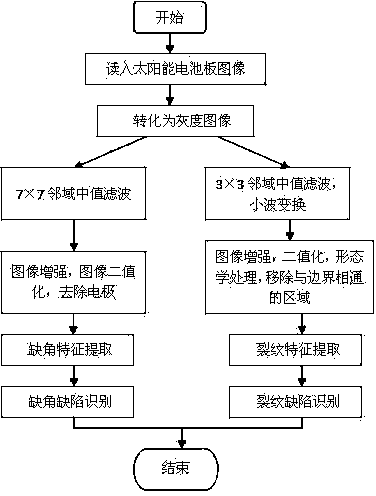

[0036] Solar cell surface defect detection equipment, the circuit includes a lighting unit, an image acquisition unit, an image processing unit, and a display unit. The lighting unit is composed of an AFT-D12 light source controller (DC 12V power adapter) and a white low-angle ring LED cold light source. (Light source controller is 12V DC power supply)

[0037] The image acquisition unit consists of MV-VS078FC CCD camera (maximum resolution 1024X768, 8-bit data output, frame rate 30fps, progressive scanning color CCD), M0814MP lens (image size 2 / 3", minimum object distance 0.1m, Focal length 8mm), MV-E1394Dual image acquisition card (using professional TSB43AB22A dual control chip, high-speed serial real-time data stream transmission, data transmission rate per channel up to 400Mb / s, 6-core interface provides 12V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com