Peanut-containing chocolate used for external coating of cold drink, and its preparation method

A chocolate and peanut technology, applied in the field of chocolate, can solve problems such as the influence of chocolate coating performance, and achieve the effect of rich taste and unique taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

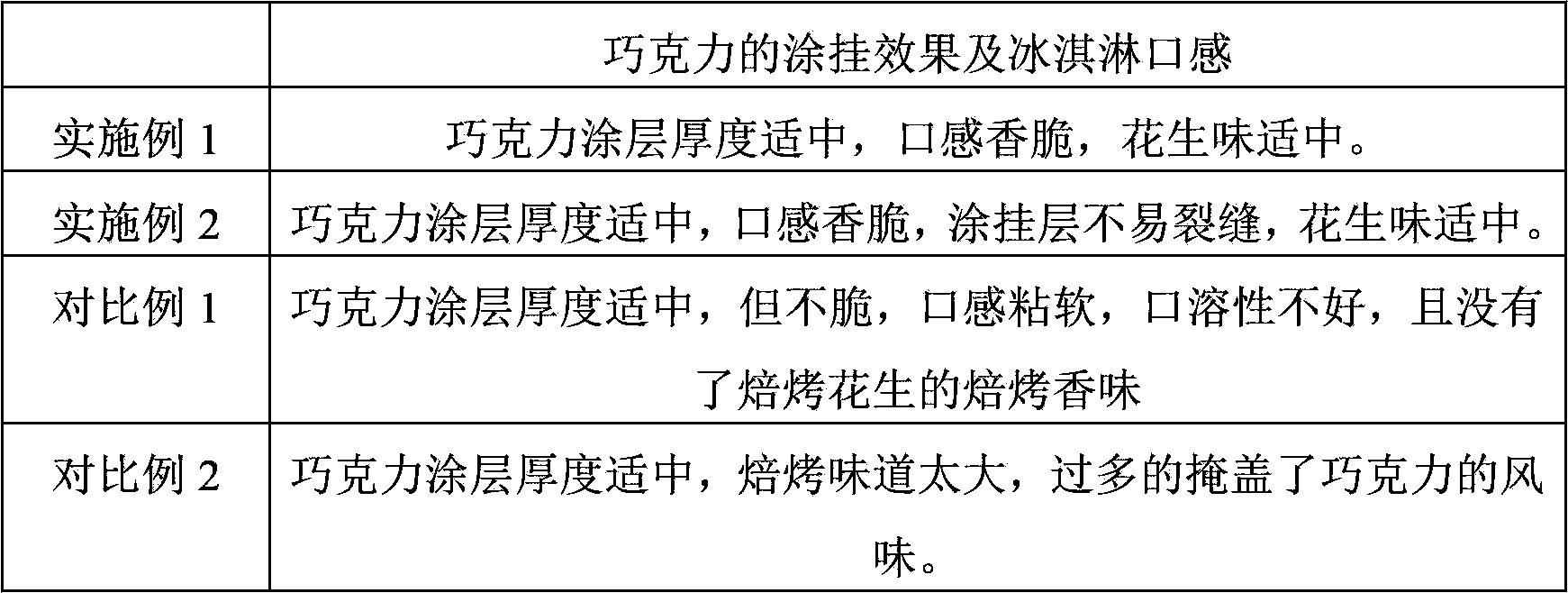

Examples

Embodiment 1

[0035] Prepare peanut flavor chocolate (100g) for cold drink coating of the present invention

[0036] Raw materials include: white sugar 22g, milk powder 12g, maltodextrin 13g, oil 45g (coconut oil 32g, palm oil 10g, cocoa mass 3g), emulsifier 0.5g (polyglyceryl castoryl PGPR900.3g, lecithin 0.2 g), roasted peanut powder 3.5g, peanut butter 4g.

[0037] Preparation of roasted peanut powder The roasted peanut powder is made from ground roasted peanuts, and the moisture content is ≤2%.

[0038] The preparation method comprises the following steps:

[0039] 1) Grind white granulated sugar into powdered sugar for later use;

[0040] 2) Heat and melt the cocoa mass;

[0041] 3) Put the melted cocoa mass together with coconut oil and palm oil into the fine grinding tank, then add the powdered sugar and other powdery materials mentioned in step 1), and stir evenly;

[0042] 4) Use a scraper-type fine grinder, first preheat the fine grinder to make the temperature reach 45-48°C, ...

Embodiment 2

[0044] Peanut-flavored chocolate (100g) for cold drink coating of the present invention.

[0045] Raw materials include: white sugar 19g, milk powder 8g, maltodextrin 9g, oil 52.5g (palm oil 46g, cocoa butter 6.5g), emulsifier 1.0g (polyglyceryl ricinoleate PGPR900.48g, lecithin 0.52g), Roasted peanut powder 4g, peanut butter 6g.

[0046] The preparation method comprises the following steps:

[0047] 1) Grind white granulated sugar into powdered sugar for later use;

[0048] 2) Heat the cocoa butter and melt it;

[0049] 3) Put the melted cocoa butter and palm oil into the fine grinding tank, then add the powdered sugar and other powdery materials in step 1), and stir evenly;

[0050] 4) Use a ball mill to raise the temperature to 65-68°C, keep it warm for 30-40 minutes, then cool down to the fine grinding temperature, keep the fine grinding temperature at 50-60°C, and finish the fine grinding for 3 hours to make chocolate; Add lecithin when grinding for 10 minutes, add pe...

Embodiment 3

[0052] Peanut-flavored chocolate (100g) for cold drink coating of the present invention.

[0053]Raw materials include: 20.4g of white sugar, 10.2g of milk powder, 11.4g of maltodextrin, 49.14g of oil (16.3g of palm oil, 30.8g of coconut oil, 2.04g of cocoa butter), 0.86g of emulsifier (polyglyceryl ricinoleate PGPR900 .4g, lecithin 0.46g), roasted peanut powder 3g, peanut butter 5g.

[0054] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com