Method for removing arsenic in aloe

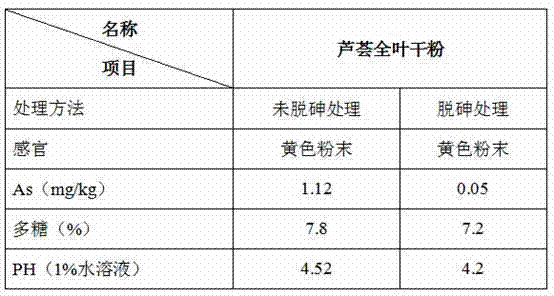

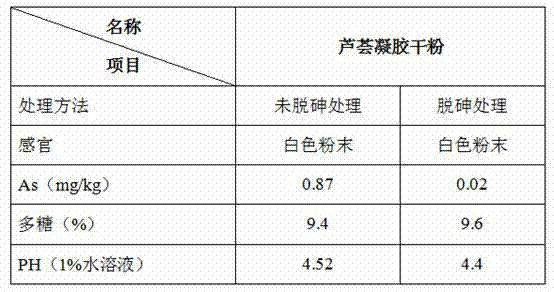

An aloe vera removal technology, which is applied in the direction of medical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of high arsenic content in aloe vera, exceeding the standard, etc., and achieve good economic and social benefits and removal effects Good, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A, the aloe leaves are washed, squeezed and sterilized to obtain aloe pulp;

[0024] B. According to the amount of 50ml / t aloe vera juice, add pectinase to the aloe vera juice obtained in step A, carry out enzymolysis at 50°C for 60 minutes, then add diatomaceous earth according to 0.15% of the mass of aloe vera pulp, stir and mix well Filtration, the filtrate is subjected to high temperature instantaneous sterilization (UHT), and then cooled to below 30°C to obtain aloe juice with a soluble solid content of 1.5%;

[0025] C, according to the volume ratio of aloe juice: macroporous anion exchange resin=25:1, the aloe juice obtained in step B is passed through the commercially available food industry macroporous anion exchange resin column, and the contact time is controlled for 20min to obtain the aloe juice for removing arsenic I;

[0026] D. According to the volume ratio of aloe juice I: strong acid cation exchange resin=35:1, pass the aloe juice I obtained in step C...

Embodiment 2

[0031] A, the aloe leaves are washed, peeled, squeezed, and sterilized to obtain aloe pulp;

[0032] B. According to the amount of 80ml / t aloe vera juice, add pectinase to the aloe vera juice obtained in step A, carry out enzymolysis at 53°C for 50 minutes, then add diatomaceous earth according to 0.2% of the mass of aloe vera pulp, stir and mix well Filtration, after the filtrate is subjected to high-temperature instantaneous sterilization (UHT), and then cooled to below 30 ° C, the aloe juice with a soluble solid content of 0.5% is obtained;

[0033] C, according to the volume ratio of aloe juice: macroporous anion exchange resin=20:1, the aloe juice obtained in step B is passed through the commercially available macroporous anion exchange resin column for the food industry, and the contact time is controlled for 25min to obtain arsenic-removed aloe juice I;

[0034] D. According to the volume ratio of aloe juice I: strong acid cation exchange resin=30:1, pass the aloe juic...

Embodiment 3

[0039] A, the aloe leaves are washed, squeezed and sterilized to obtain aloe pulp;

[0040] B. According to the amount of 100ml / t aloe vera juice, add pectinase to the aloe vera juice obtained in step A, carry out enzymolysis at 55°C for 40 minutes, then add diatomaceous earth according to 0.1% of the mass of aloe vera pulp, stir and mix well Filtration, the filtrate is subjected to high-temperature instantaneous sterilization (UHT), and then cooled to below 30°C to obtain aloe juice with a soluble solid content of 2.0%;

[0041] C, according to the volume ratio of aloe juice: macroporous anion exchange resin=30: 1, the aloe juice obtained in step B is passed through the macroporous anion exchange resin column for food industry purchased in the market, and the contact time is controlled for 30min to obtain the aloe juice for removing arsenic I;

[0042] D. According to the volume ratio of aloe juice I: strong acid cation exchange resin=32:1, pass the aloe juice I obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com