Nozzle heating device and temperature control system and method for amorphous strip preparation

A technology of a temperature control system and a control method, which is applied in the field of amorphous thin strip manufacturing, can solve problems such as nozzle blockage and constant nozzle temperature, and achieve the effects of avoiding heating, uniform temperature and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

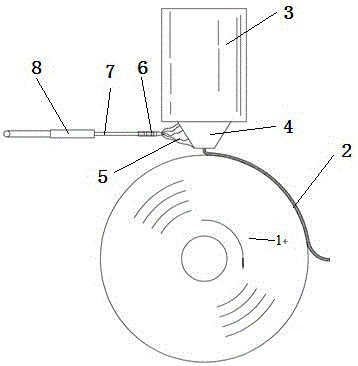

[0045] The nozzle heating device for the preparation of amorphous strip according to the present invention, such as figure 1 As shown, the flame heating device 7 is included. In this embodiment, on the actual equipment, the nozzle 4 is installed under the nozzle package 3, and the flame heating device 7 is arranged on one side of the nozzle 4, which can be around the nozzle 4. On any side, and the flame heating device 7 can be set horizontally with the nozzle 4, or at a certain angle, depending on the needs of the industry. In this embodiment, the flame heating device 7 is provided with one, horizontal It is arranged on one side of the nozzle 4, so that the flame 5 can be sprayed on the side wall of the nozzle 4, and the nozzle 4 is heated, so that the temperature of the nozzle 4 will not decrease with the rotation of the cooling roller 1, and the nozzle 4 is prevented from falling with the rotation of the cooling roller 1. When the cooling roll 1 is rotated and the temperatur...

Embodiment 2

[0053] On the basis of the nozzle heating device described in Embodiment 1, two flame heating devices 7 are arranged on opposite sides of the nozzle respectively, and the flame heating device 7 is a flame spray gun in this embodiment, Such as Figure 4 As shown, the flame spray gun is provided with at least one gun head 6, and when the nozzle width is 142mm, the gun head 6 is provided with 6-8 in the present embodiment, and the position of the gun head 6 is usually far from the flame There is a certain distance on the edge of the spray gun, and at the same time, there is a distance of at least 20mm between each of the gun heads 6. In order to ensure that the flame 5 ejected by the flame spray gun during the left and right translation process can always cover the entire length range of the nozzle 4, And excluding the influence of edge effects, the width of the flame spray gun is at least twice the length of the nozzle 4 . The shape of the gun head 6 is flat and long in this em...

Embodiment 3

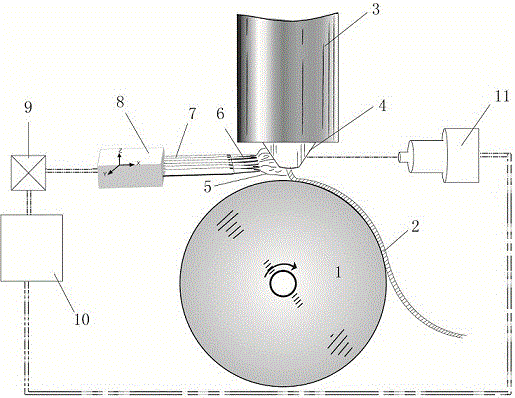

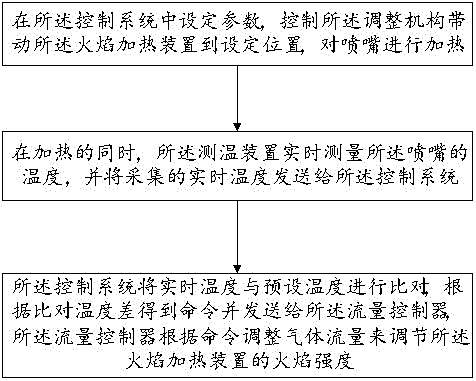

[0057] A temperature control system using the nozzle heating device described in the above embodiments, such as figure 2 As shown, it includes a temperature measuring device 11, a control unit 10 and the nozzle heating device. The temperature measuring device 11 is preferably an infrared thermometer, and the infrared thermometer can be used to realize remote non-contact temperature measurement. In the prior art, the problem of using the thermistor to measure at a high temperature position is high consumption and equipment loss is fast, and the infrared thermometer is a relatively advanced temperature remote measurement technology at present, and its measurement is accurate and fast, and can quickly and accurately reflect The change of temperature, described infrared thermometer is arranged on the side of nozzle 4, and its position is with the distance of the farthest accurate measurement nozzle 4 temperature, is horizontally arranged on nozzle 4 side in the present embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com