Rubber dipping type insulation gloves and manufacture method thereof

An insulating glove and impregnated technology, applied in protective clothing, etc., can solve problems such as unstable insulation performance, poor softness, and unsightly appearance, and achieve the effects of overcoming electrical breakdown, good water repellency, and good cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Take the insulating gloves for live work of level 00 as an example to illustrate

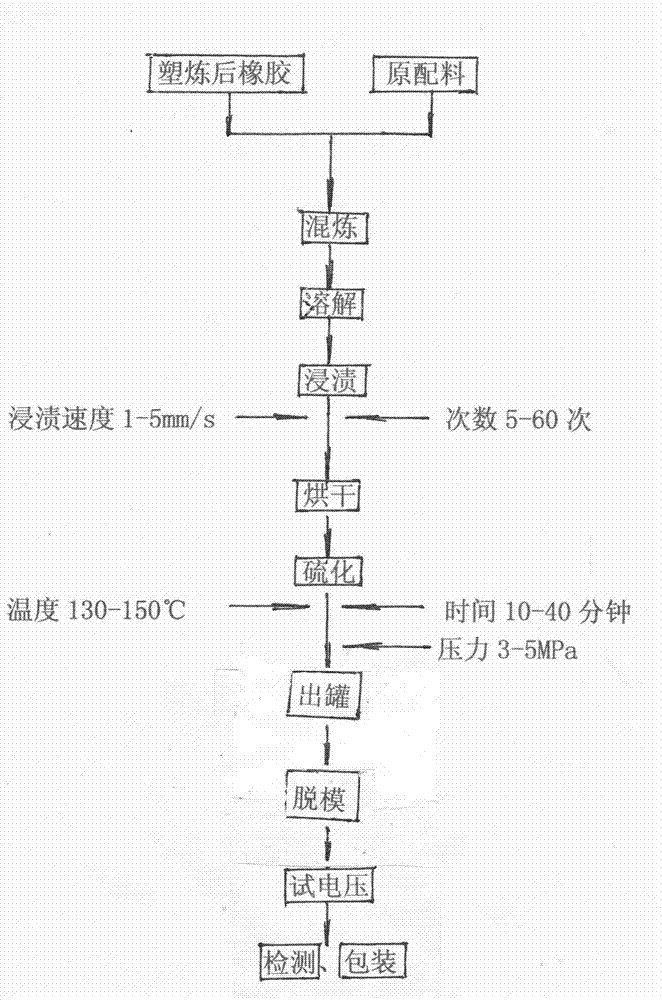

[0037] Such as figure 1 Shown: the rubber-impregnated insulating gloves, characterized in that: the composition of the impregnating solution includes the following raw ingredients proportioned by parts:

[0038] 100 parts of natural rubber, 3.0 parts of zinc oxide,

[0039] 2.0 parts of sulfur, 1.0 parts of accelerator,

[0040] 1.0 parts of anti-aging agent, 1.5 parts of stearic acid,

[0041] 20.0 parts of light calcium carbonate;

[0042] The steps of the manufacturing method of its rubber-impregnated insulating gloves are as follows:

[0043] ①. Dissolve the masticated rubber and the above-mentioned raw ingredients together into a liquid with a rubber solvent after conventional mixing;

[0044] ②. Immerse the glove model in the above liquid 10 times through the impregnation equipment, and the impregnation speed is 1.0mm / s and need to be dried...

Embodiment 2

[0049] Example 2 Take rubber-impregnated insulating gloves for Class 4 live work as an example to illustrate

[0050] Such as figure 1 Shown: the rubber-impregnated insulating gloves, characterized in that: the composition of the impregnating solution includes the following raw ingredients proportioned by parts:

[0051] 100 parts of natural rubber, 3.0 parts of zinc oxide,

[0052] 3.0 parts of sulfur, 2.0 parts of accelerator,

[0053] 2.0 parts of anti-aging agent, 1.5 parts of stearic acid,

[0054] Light calcium carbonate 18.0 parts.

[0055] The steps of the manufacturing method of its rubber-impregnated insulating gloves are as follows:

[0056] ①. Dissolve the masticated rubber and the above-mentioned raw ingredients together into a liquid with a rubber solvent after conventional mixing;

[0057] ②. Immerse the glove model in the above liquid 60 times through the impregnation equipment, and the impregnation speed is 1.0mm / s and need to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com