Novel circulating mixing device

A circular mixing and new technology, applied in the direction of enzyme production/bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve problems affecting product quality and material yield, slow material reaction speed, low catalytic hydrolysis rate, etc. Achieve the effects of light specific gravity, complete material reaction and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

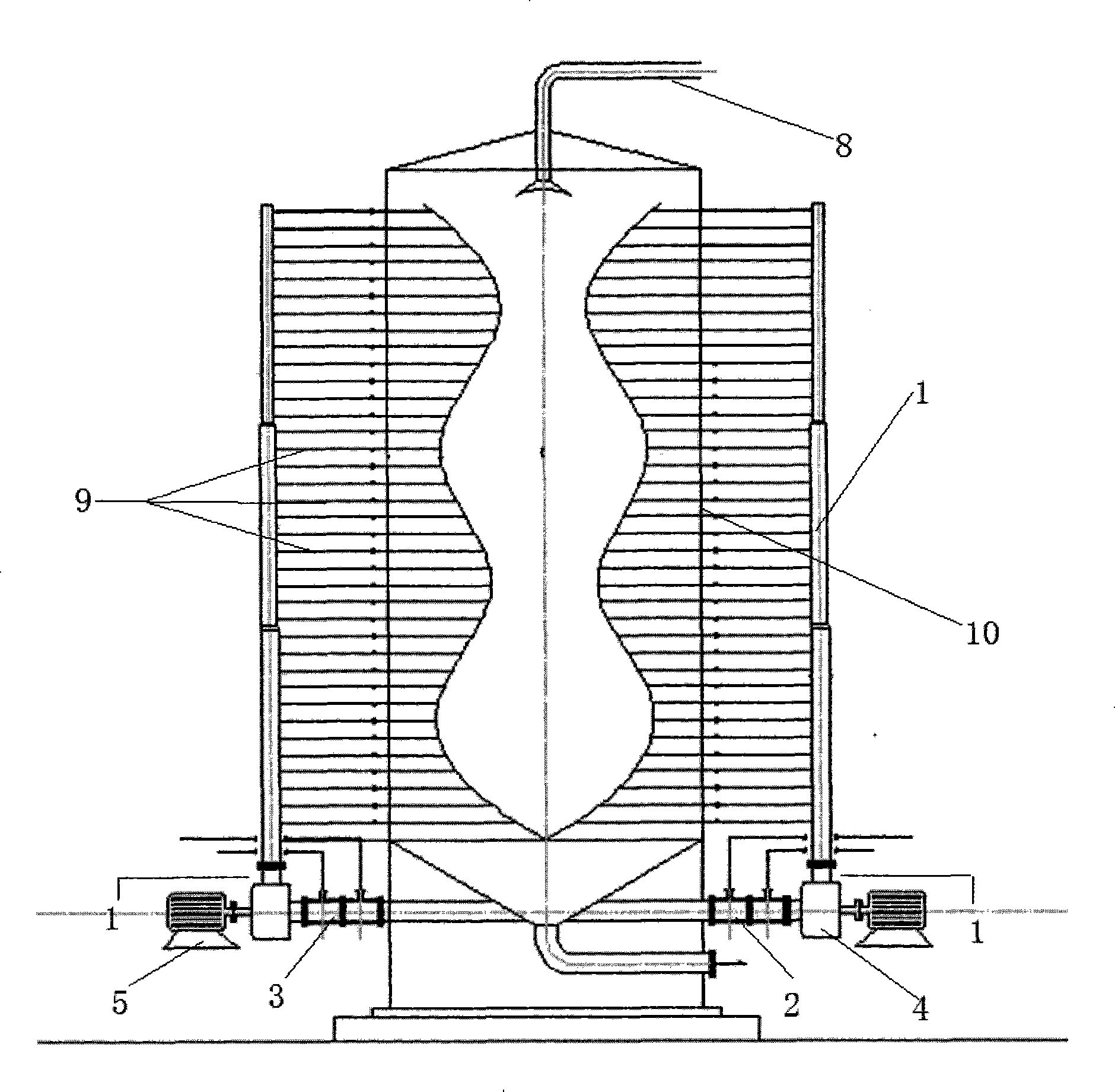

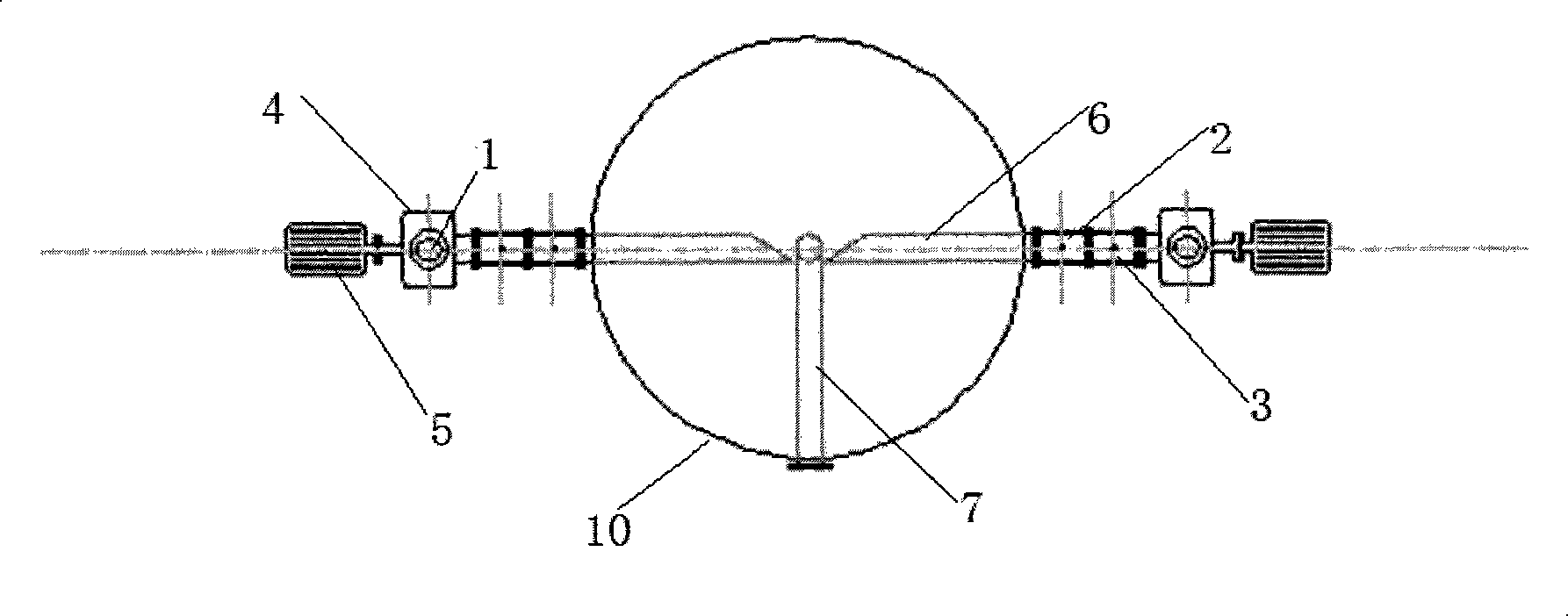

[0031] In order to better understand the present invention, preferred embodiments of the circulating mixing device according to the present invention will be described below with reference to the accompanying drawings.

[0032] See attached Figure 1-2 , a new circulation mixing device, including feeding pipe 1, enzyme adding device 2, alkali adding device 3, centrifugal pump 4, centrifugal pump motor 5, inlet pipe 6, discharge pipe 7, feeding pipe 8, branch pipe 9 and mixing Tank 10, feeding pipe 8 is arranged on the top of mixing tank 10, and two feeding pipes 1 are vertically arranged on both sides of mixing tank 10 respectively; The diameter increases sequentially from top to bottom, and the material flow rate and flow velocity in the feed pipe 1 increase as the diameter decreases; a plurality of branch pipes 9 are arranged horizontally and parallel to each other in the vertical direction, and one end of the pipe is connected to the feed pipe. 1 connected, the number of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com