An economical and clean method for leaching cobalt from high-valent cobalt oxides

A cobalt oxide and clean technology, applied in the field of cobalt metallurgy, can solve the problems of difficult operation, increased burden of cobalt smelting cost, complicated and easy corrosion of equipment, etc., to simplify the leaching process, improve economic and environmental benefits, and reduce production energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

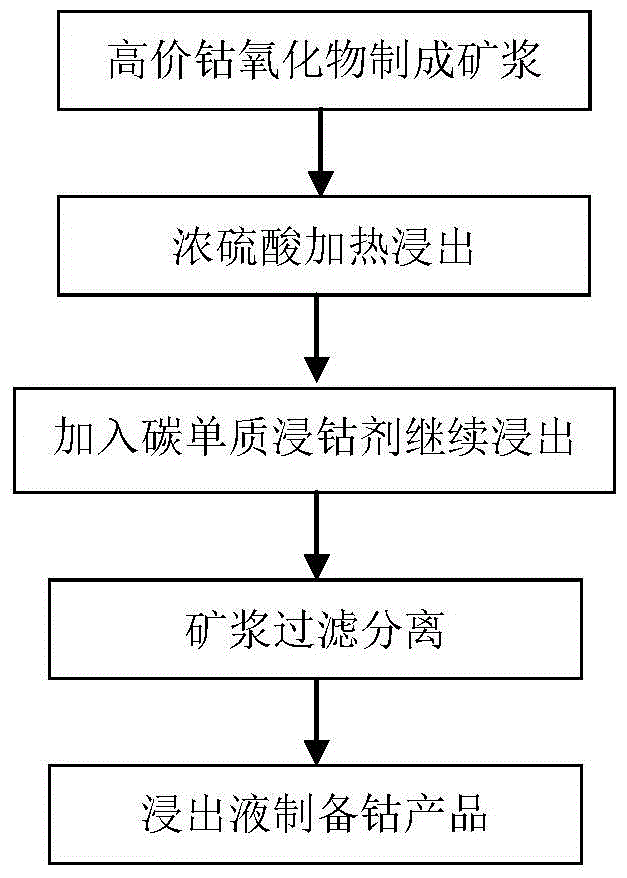

Method used

Image

Examples

Embodiment 1

[0023] The raw material is cobalt ore, which is prepared into slurry with a concentration of 30%, and the amount of sulfuric acid added is 100kg / t dry base ore, heated to 90°C, leaching time is 5h, and the copper leaching rate reaches 80%. Data are as follows:

[0024] co Fe Mg mn Al Ni Ca Cu A factory cobalt mine 4.45 5.9 3.54 3.34 4.27 0.082 0.28 11.67 Sulfuric acid leaching residue 4.25 7.16 4.49 3.07 5.41 0.063 0.08 1.31

[0025] No carbonaceous cobalt leaching agent was added in this example, and the cobalt was hardly leached.

Embodiment 2

[0027] The raw material is cobalt ore, which is prepared into pulp with a concentration of 50%. The amount of sulfuric acid added is 200kg / t dry base ore, heated to 70°C, and activated carbon powder is added after leaching for 1 hour. The amount of activated carbon powder added is 200kg / t dry base ore. The leaching continued for 8 hours unchanged, and the cobalt leaching rate reached 88%.

Embodiment 3

[0029] The raw material is cobalt ore, which is prepared into a slurry with a concentration of 20%. The amount of sulfuric acid added is 300kg / t dry base ore, heated to 95°C, and coke powder is added after leaching for 0.5h. The amount of coke powder added is 300kg / t dry base ore. The leaching was continued for 3 hours without changing the temperature, and the leaching rate of cobalt reached 99%. The specific data are as follows:

[0030] co Fe Mg mn Al Ni Ca Cu A factory cobalt mine 4.45 5.9 3.54 3.34 4.27 0.082 0.28 11.67 carbon leaching agent slag 0.017 5.33 2.98 0.088 4.12 0.063 <0.05

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com