A method for extracting tungsten from low-grade wolframite

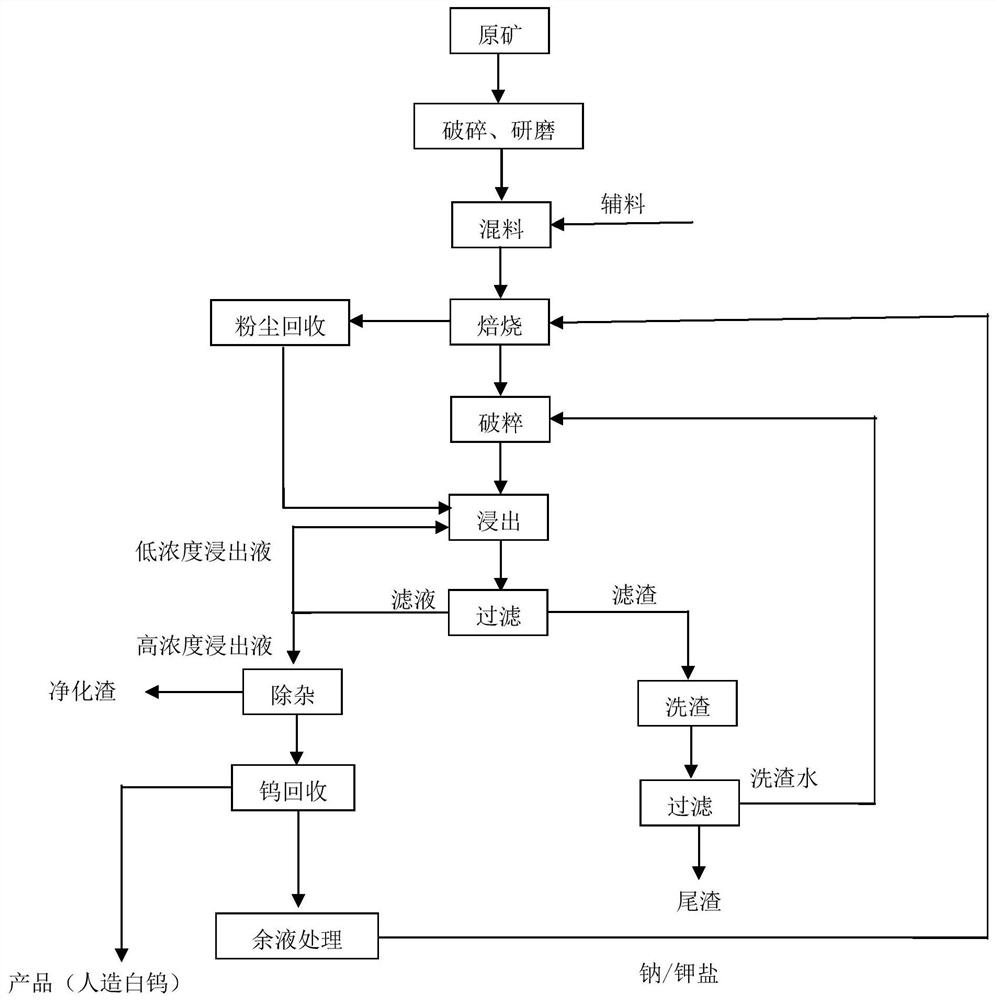

A low-grade tungsten iron ore technology, applied in the field of tungsten extraction, can solve the problems of difficult to realize industrialization, complex leaching conditions, easy sintering of materials, etc., and achieve the effect of simplifying the leaching process, good material flow, and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 100g of tungsten ore and pour it into an electromagnetic sample grinder. After processing, tungsten ore becomes powder with a particle size of about 100 μm. Add 0.20 times the amount of soda ash, 0.03 times the amount of magnesium chloride and 0.11 times the amount of sodium chloride , mix the auxiliary materials with the finely ground ore samples evenly, place them in a muffle furnace and heat them to 780°C, keep them warm for 60 minutes, and after cooling with the furnace, process them into a particle size of 100-150 μm with an electromagnetic sample preparation grinder. At 2 minutes and 45 seconds, ultrasonic water immersion, leaching in a water bath at 70°C for 45 minutes, the leaching liquid-solid ratio is 3:1 (mL / g), filtering and analyzing the silicon and phosphorus impurities in the filtrate, the result is Si: 8.21mg / L, P: 6.28 mg / L. The filter cake was stirred and washed once with 1.5 times of water, and the filter residue was weighed after drying, and th...

Embodiment 2

[0047] Weigh 100g of tungsten ore and pour it into an electromagnetic sample grinder. After processing, tungsten ore becomes powder with a particle size of about 100 μm. Add 0.22 times the amount of soda ash, 0.10 times the sodium chlorate and 0.05 times the magnesium chloride of the ore sample. , mix the auxiliary materials with the finely ground ore samples evenly, place them in a muffle furnace, heat them to 800°C, and keep them warm for 30 minutes. After 2 minutes and 30 seconds, add the tungsten-containing leaching solution of Example 1 for ultrasonic circulation leaching, dilute hydrochloric acid to fine-tune the pH to 9-10, and leaching for 30 minutes in a water bath at 75°C. The ratio of leaching liquid to solid is 3:1 (mL / g). The cake was stirred and washed once with 1.5 times of water, and the filter residue was weighed after drying, and the WO 3 content, and calculate the extraction rate of tungsten. The analysis result of filter residue is 0.14%, and the calculati...

Embodiment 3

[0052] Weigh 100g of tungsten ore and pour it into an electromagnetic sample grinder, process the tungsten ore into powder with a particle size of about 100μm, add 0.18 times the amount of soda ash, 0.12 times the sodium sulfate and 0.05 times the magnesium sulfate of the ore sample , mix the auxiliary materials with the finely ground ore samples evenly, place them in a muffle furnace, heat them to 850°C, and keep them warm for 45 minutes. At 1 minute and 45 seconds, ultrasonic water immersion, leaching in a water bath at 70°C for 60 minutes, the liquid-solid ratio of the leaching is 3:1 (mL / g), after filtration, the filter cake is stirred and washed once with 1.5 times of water, and the filter residue is dried and weighed. Sampling and analyzing the WO 3 content, and calculate the extraction rate of tungsten. The analysis result of filter residue is 0.15%, and the calculation method of tungsten extraction rate is =(1-m 2 ×ω 2 / m 1 ×ω 1 )×100%

[0053] where m 1 、m 2 R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com