Optical parameter detecting method for Si-based buffer layer coated glass

A technology for coating glass and optical parameters, which is applied in the direction of using optical devices, testing optical properties, measuring devices, etc., can solve detection deviation, difficult to design and optimize the optical characteristics of the overall film system, and difficult to accurately obtain the fine structure of the layer film and its optical properties. parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

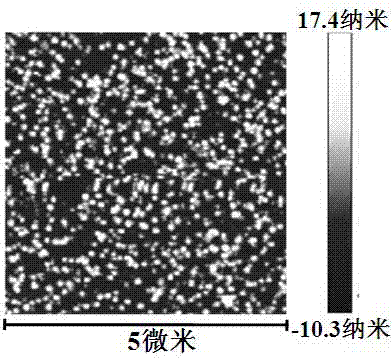

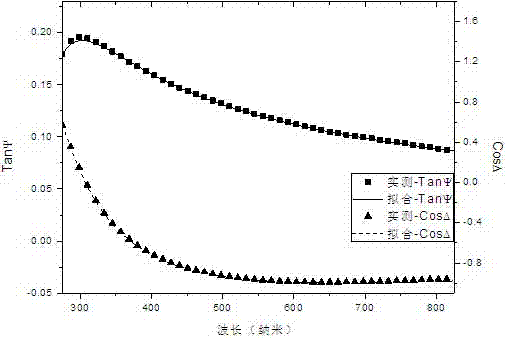

[0027] Choose a SiC x o y Buffer layer coated glass sample, 0figure 1 Shown is the particle surface. Simply clean the surface of the sample film, and measure its ellipsometric parameter cosΔ with a spectroscopic ellipsometer M and tanΨ M , the spectral range is from 275nm to 825nm, and the incident angle is set to 56°. Generated by ellipsometric parameters and established models and The specific model is as follows:

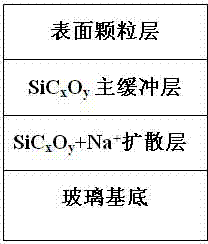

[0028] Establish a three-layer film structure model: the three-layer film structure is recorded as SiC from bottom to top on the glass substrate x o y +Na + Diffusion layer, SiC x o y The primary buffer layer as well as the surface granular layer, such as figure 2 As shown, the initial film thickness of each layer is recorded as d from the substrate up 10 =15nm, d 20 =50nm and d 30 =5nm;

[0029] Build the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com