A kind of liquid injection activation method of power battery

A power battery and liquid injection technology, which is applied in the direction of secondary batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve problems such as deterioration of battery performance, decomposition, and rise in battery internal pressure, and achieve an improved working environment and consistent improvement Sexuality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

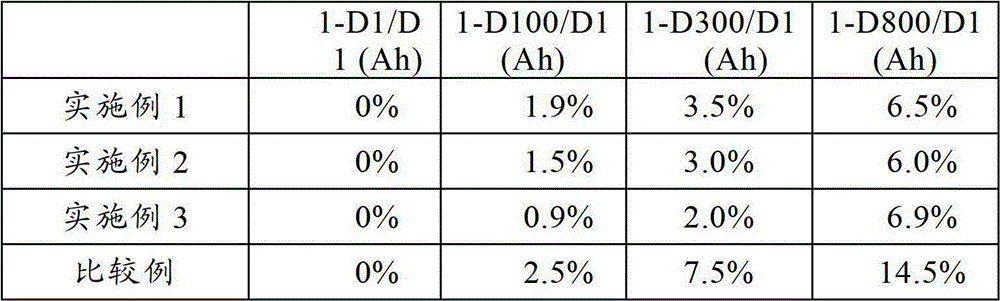

Embodiment 1

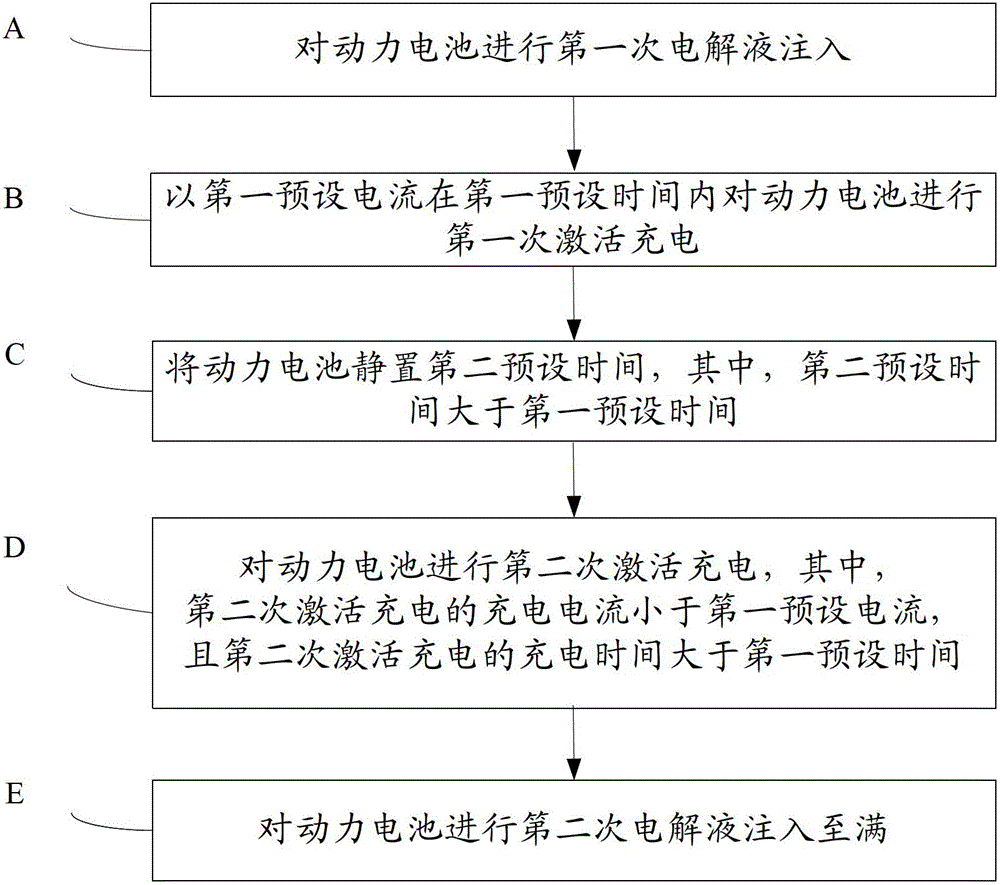

[0045] In this embodiment, the power battery injection activation is performed according to the following steps.

[0046] S1: The assembled lithium iron phosphate power battery is injected into the opening for the first time, and the amount of liquid injected is 65% of the total amount of liquid injected.

[0047] S2: Carry out the first high-current charging immediately after liquid injection, the charging current is 0.4C, and the charging time is 30S.

[0048] S3: Let the high-current rechargeable battery stand for 3-4 hours.

[0049] S4: When the standing time is up, the battery will be activated for the second time. The second activation charge is pulse constant voltage charging, which is divided into 3 stages:

[0050] In the first stage, charge the battery with a charging current of 0.03C so that the battery voltage reaches 1.5V, and then maintain a constant voltage of 1.5V to continue charging for a period of time. Generally, during constant voltage charging, as the b...

Embodiment 2

[0057] In this embodiment, the power battery injection activation is performed according to the following steps.

[0058] S1: The assembled lithium iron phosphate power battery is injected into the opening for the first time, and the amount of liquid injected is 75% of the total amount of liquid injected.

[0059] S2: Immediately after liquid injection, carry out the first high-current charging, the charging current is 0.45C, and the charging time is 30S.

[0060] S3: Let the high-current rechargeable battery stand for 3-4 hours.

[0061] S4: After the rest time is completed, the battery is charged for secondary activation. The second activation charge is a pulse constant voltage charge, which is carried out in 3 stages:

[0062] In the first stage, charge the battery with a charging current of 0.04C so that the battery voltage reaches 1.5V, and then maintain a constant voltage of 1.5V to continue charging for a period of time. Generally, during constant voltage charging, a...

Embodiment 3

[0069] In this embodiment, the power battery injection activation is performed according to the following steps.

[0070] S1: The assembled lithium iron phosphate power battery is injected into the opening for the first time, and the amount of liquid injected is 80% of the total amount of liquid injected.

[0071] S2: Immediately after liquid injection, carry out the first high-current charging, the charging current is 0.5C, and the charging time is 30S.

[0072] S3: Let the high-current rechargeable battery stand for 3-4 hours.

[0073] S4: After the rest time is completed, the battery is charged for secondary activation. The second activation charge is a pulse constant voltage charge, which is carried out in 3 stages:

[0074] In the first stage, charge the battery with a charging current of 0.05C so that the battery voltage reaches 1.5V, and then maintain a constant voltage of 1.5V to continue charging for a period of time. Generally, during constant voltage charging, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com