Nickel-metal hydride battery pack for pure electric bus

A bus, pure electric technology, applied in the direction of electric vehicles, nickel storage batteries, battery pack components, etc., to achieve the effect of increasing heat dissipation area, shunting less heat generation, and faster speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described.

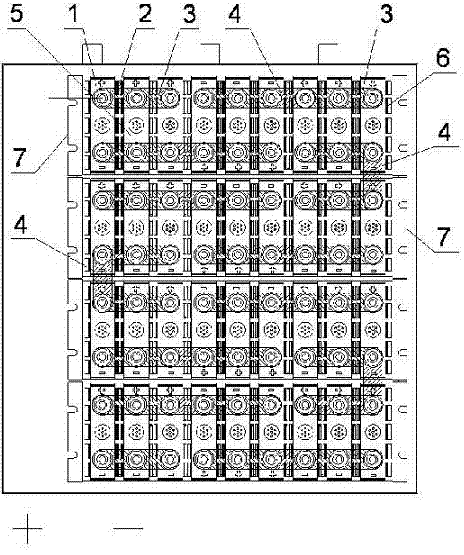

[0011] see figure 1 , a pure electric bus nickel metal hydride battery pack, including a single battery 1, a separator 2 and a battery connecting plate 3, and also includes a unit connecting plate 4, the single battery 1 is connected in parallel by the battery connecting plate 3 to form a battery unit 5; the battery unit 5 The unit connection plates 4 are connected in series to form battery modules 7 , and the battery modules 7 are connected in series to form a battery box by the unit connection plates 4 .

[0012] The internal resistance of each single battery 1 in the battery unit 5 is the same. The capacity of each battery unit 5 in the battery module 7 is the same. There are three single cells 1 in the battery unit 5 . A clamp 6 is provided on the battery module 7 . The partition plate 2 is a through-hole fixed plate formed by injection molding of flame-retardant PP material.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com