Method for producing wettable powder through compound of validamycin A and propiconazole

A technology of wettable powder and Jinggangmycin, which is applied in the field of pesticides, can solve the problems of poor product quality and achieve the effects of convenient operation, high suspension rate and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

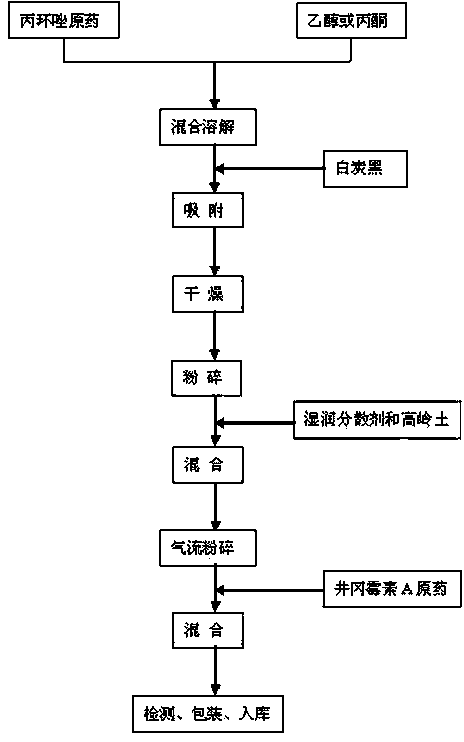

Method used

Image

Examples

Embodiment 1

[0020] Weigh 22.4 kg of the original drug containing 95% of propiconazole, dissolve it by heating with 50 liters of industrial absolute ethanol; stir and adsorb with 20 kg of white carbon black for half an hour, and then vacuum dry the white carbon black adsorbent for 3 hours. The temperature is controlled at 65℃; the dried material is pulverized initially, and then 8 kg of wetting and dispersing agent DT-801 additives, 5 kg of DT-882-2 additives and 35.9 kg of kaolin are added for mixing for 2 to 3 hours; Air jet pulverization, adding 6.7 kg of Jinggangmycin A original drug with a content of 60%, and mixing for 2 to 3 hours. After multi-point sampling and testing, ①The content of Jinggangmycin A and propiconazole were 4.1% and 20.2%, respectively, and the suspension rate was 90.2%; ②The content of Jinggangmycin A and propiconazole were 4.2% and 20.1%, respectively, and the suspension rate It was 90.1%; ③The content of Jinggangmycin A and propiconazole were 4.0% and 20.2%, resp...

Embodiment 2

[0022] Weigh 33.6 kg of the original drug containing 95% of propiconazole and heat it with 75 liters of industrial absolute ethanol to dissolve it; stir and adsorb with 30 kg of white carbon black for half an hour, and then vacuum dry the white carbon black adsorbent for 3 hours. The temperature is controlled at 65℃; the dried material is pulverized initially, and 12 kg of wetting and dispersing agent DT-801 additives, 7.5 kg of DT-882-2 additives and 53.85 kg of kaolin are added for mixing for 2 to 3 hours; Air jet pulverization, add 10.05 kg of Jinggangmycin A original drug with a content of 60%, and mix for 2 to 3 hours. After multi-point sampling and testing, ①The content of Jinggangmycin A and propiconazole were 4.2% and 20.1%, respectively, and the suspension rate was 90.3%; ②The content of Jinggangmycin A and propiconazole were 4.3% and 20.2%, respectively, and the suspension rate 90.2%; ③The content of Jinggangmycin A and propiconazole were 4.1% and 20.2%, respectively,...

Embodiment 3

[0024] Weigh 40.32 kg of the original drug containing 95% of propiconazole and dissolve it by heating with 90 liters of industrial acetone; stir and adsorb with 36 kg of silica for half an hour, and then vacuum dry the silica adsorbate for 3 hours, with temperature control At 65°C; the dried material is pulverized initially, and then 14.4 kg of wetting and dispersing agent DT-801 additive, 9 kg of DT-882-2 additive and 64.62 kg of kaolin are added for mixing for 2 to 3 hours; then airflow crushing , Add 12.06 kg of Jinggangmycin A original drug with a content of 60%, and mix for 2 to 3 hours. After multi-point sampling and testing, ①The content of Jinggangmycin A and propiconazole were 4.3% and 20.1%, respectively, and the suspension rate was 90.4%; ②The content of Jinggangmycin A and propiconazole were 4.2% and 20.2%, respectively, and the suspension rate It was 90.3%; ③The content of Jinggangmycin A and propiconazole were 4.4% and 20.3%, respectively, and the suspension rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com