Automatic pressure stabilizing control device for steam of methanol distillation system and control method of control device

A control device and control method technology, applied in the direction of distillation adjustment/control, chemical instruments and methods, and preparation of hydroxyl compounds, which can solve the problems of temperature changes in each tower, increased steam consumption, and insufficient calorific value of low-pressure steam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

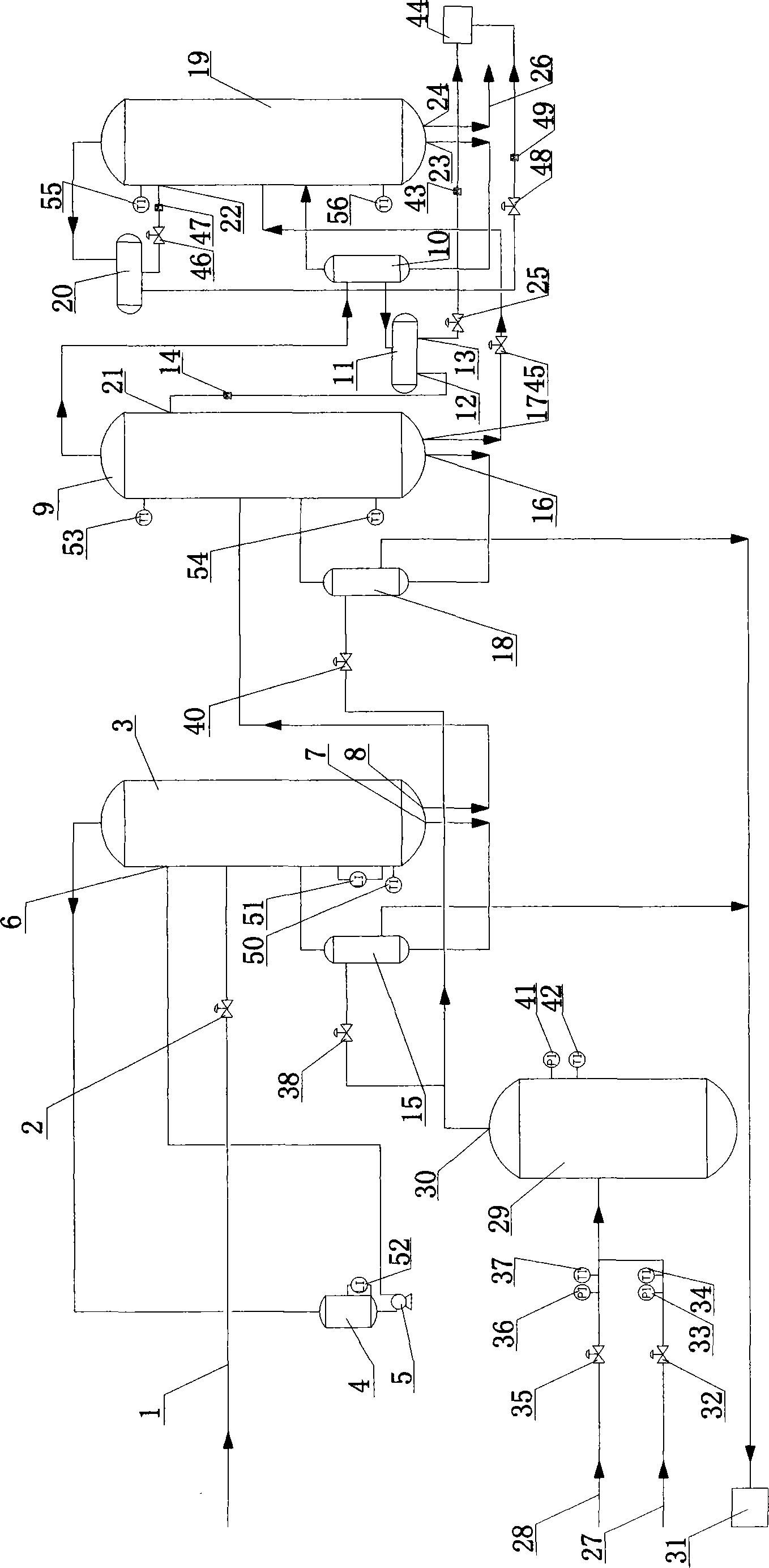

Image

Examples

Embodiment 1

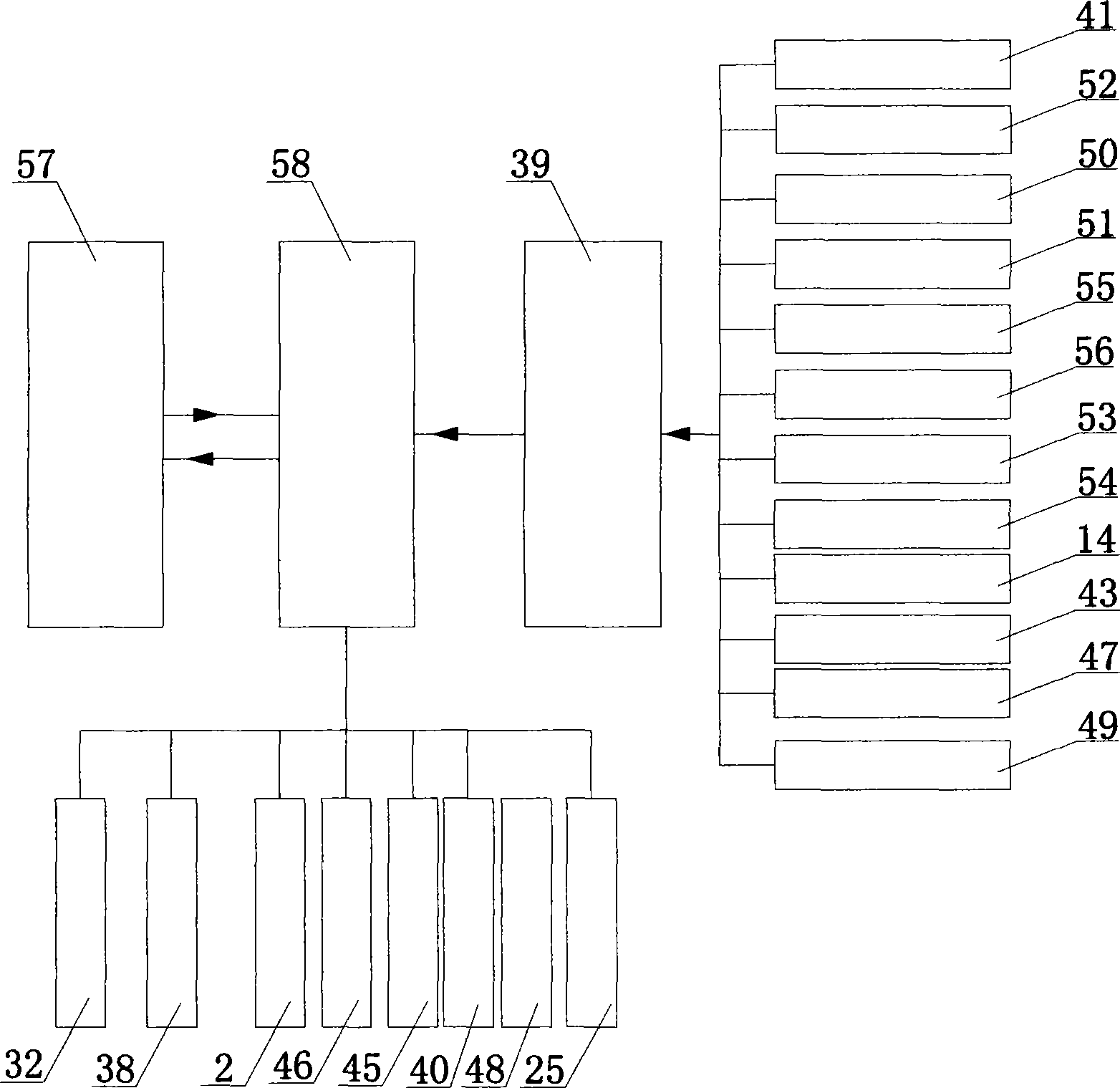

[0072] A control method for a steam automatic pressure stabilization control device in a methanol rectification system, the control method includes a method for controlling the pressure of a steam buffer tank, a method for controlling the liquid level of a reflux tank in a pre-rectification tower, and a method for controlling the bottom temperature of the pre-rectification tower , the control method of the liquid level at the bottom of the pre-rectification tower, the control method of the temperature at the top of the atmospheric column, the control method of the bottom temperature of the atmospheric column, the control method of the temperature at the top of the pressurized column and the temperature at the bottom of the pressurized column, usually The control method of the reflux ratio of the pressurized column and the control method of the reflux ratio of the pressurized column;

[0073] a. The steam buffer tank pressure control method comprises the following steps:

[007...

Embodiment 2

[0092] A control method for a steam automatic pressure stabilization control device in a methanol rectification system, the control method includes a method for controlling the pressure of a steam buffer tank, a method for controlling the liquid level of a reflux tank in a pre-rectification tower, and a method for controlling the bottom temperature of the pre-rectification tower , the control method of the liquid level at the bottom of the pre-rectification tower, the control method of the temperature at the top of the atmospheric column, the control method of the bottom temperature of the atmospheric column, the control method of the temperature at the top of the pressurized column and the temperature at the bottom of the pressurized column, usually The control method of the reflux ratio of the pressurized column and the control method of the reflux ratio of the pressurized column;

[0093] a. The steam buffer tank pressure control method comprises the following steps:

[009...

Embodiment 3

[0112] A control method for a steam automatic pressure stabilization control device in a methanol rectification system, the control method includes a method for controlling the pressure of a steam buffer tank, a method for controlling the liquid level of a reflux tank in a pre-rectification tower, and a method for controlling the bottom temperature of the pre-rectification tower , the control method of the liquid level at the bottom of the pre-rectification tower, the control method of the temperature at the top of the atmospheric column, the control method of the bottom temperature of the atmospheric column, the control method of the temperature at the top of the pressurized column and the temperature at the bottom of the pressurized column, usually The control method of the reflux ratio of the pressurized column and the control method of the reflux ratio of the pressurized column;

[0113] a. The steam buffer tank pressure control method comprises the following steps:

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com