Low-energy-consumption purification device

A purification device and low-energy-consumption technology, applied in separation devices, chemical instruments and methods, and the use of liquid separation agents, can solve problems such as condensation and separation of volatile organic compounds, and achieve the goal of expanding the range of treatable temperatures and improving the efficiency of adsorption treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

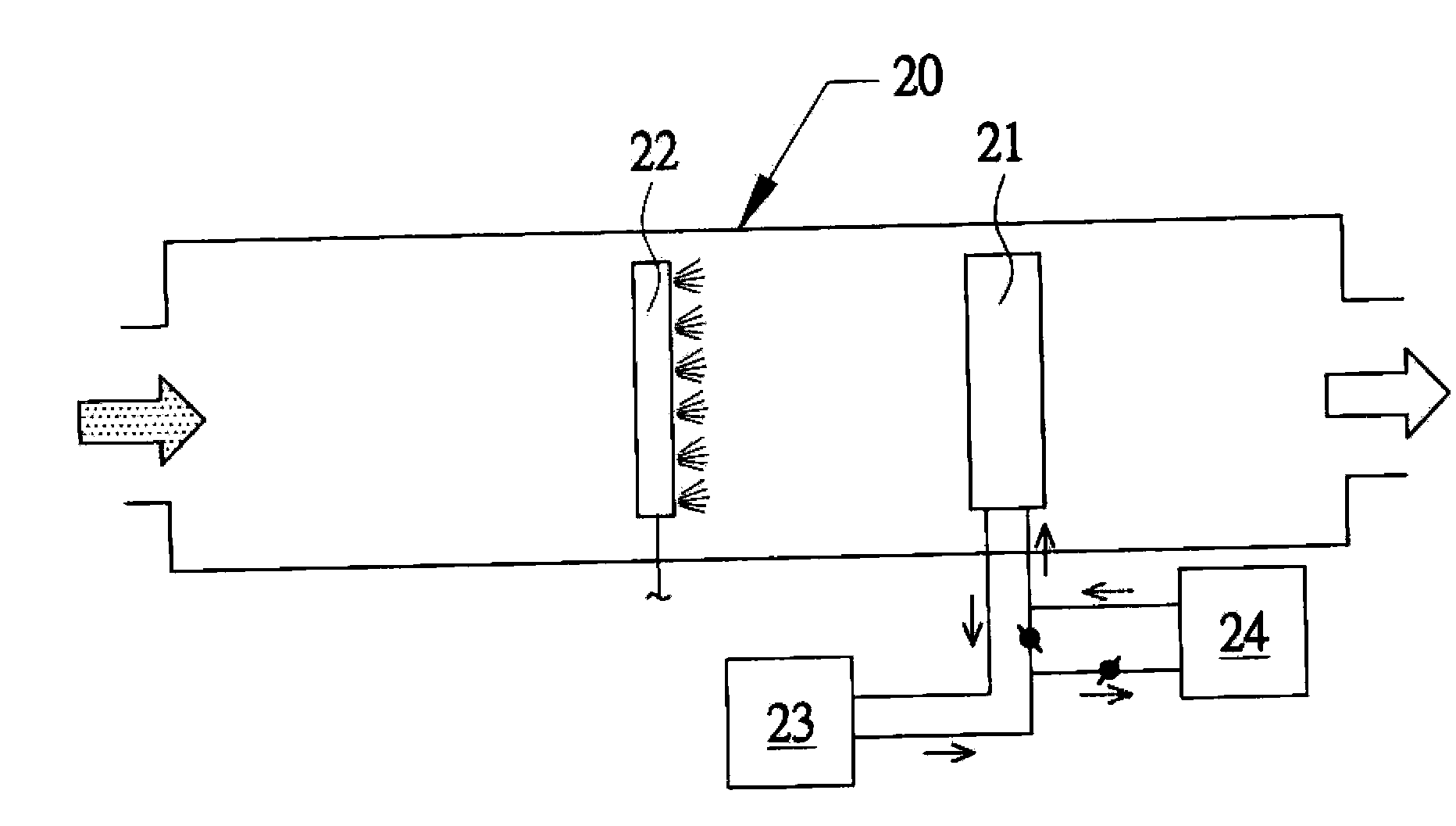

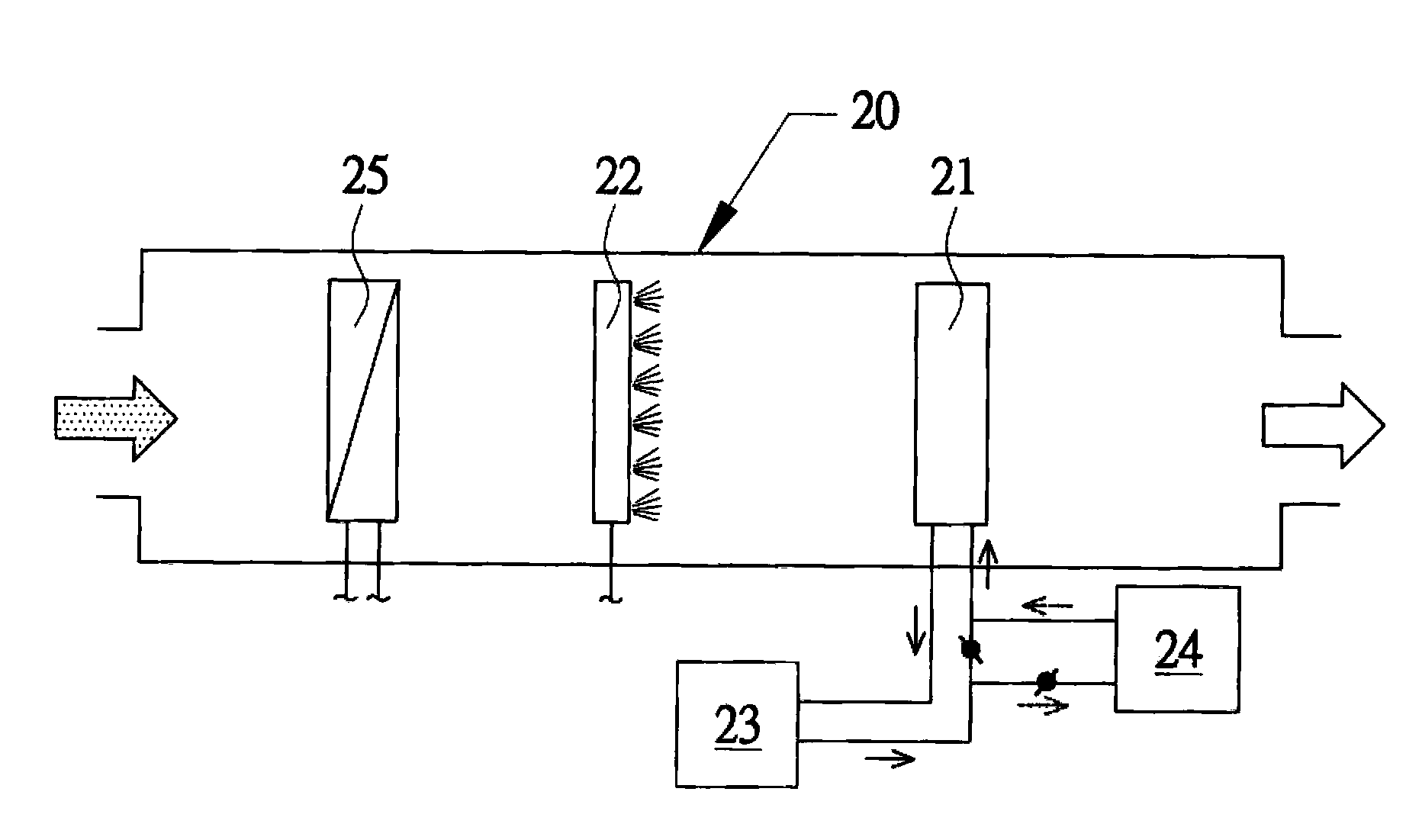

[0028] First, see the " figure 2 As shown in ", the first embodiment of the low-energy purification device of the present invention includes: a humidifier 22, which is arranged inside a to-be-purified airflow channel 20, and is used to increase the humidity by spraying water mist on the passing airflow to be purified. In addition to increasing the dew point temperature, it can also be cooled and used to remove substances to be purified (volatile organic compounds or suspended particles); a condenser 21 is arranged inside the airflow channel 20 to be purified and is located at the downstream end of the humidifier 22 for Condensing the humidified gas stream to be purified to produce a condensate containing substances to be purified (volatile organic compounds or suspended particles); and a heat exchanger 23 connected to the condenser 21 to allow the condenser 21 to achieve the expected condensation temperature, and the heat exchanger 23 is a cooling water tower, and even furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com