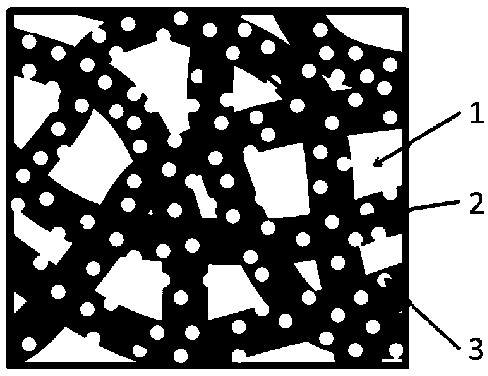

Composite filter membrane with multidimensional pore structure and preparation method thereof

A pore structure, composite filtration technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unsuitability for large-scale production and promotion, low mechanical strength, and high production costs, and achieve low production costs. , The production process is simple, and the filtering effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

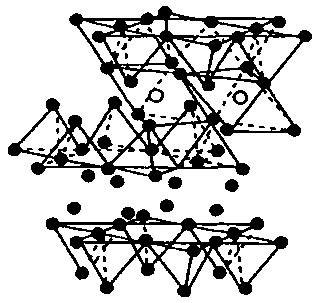

Method used

Image

Examples

Embodiment 1

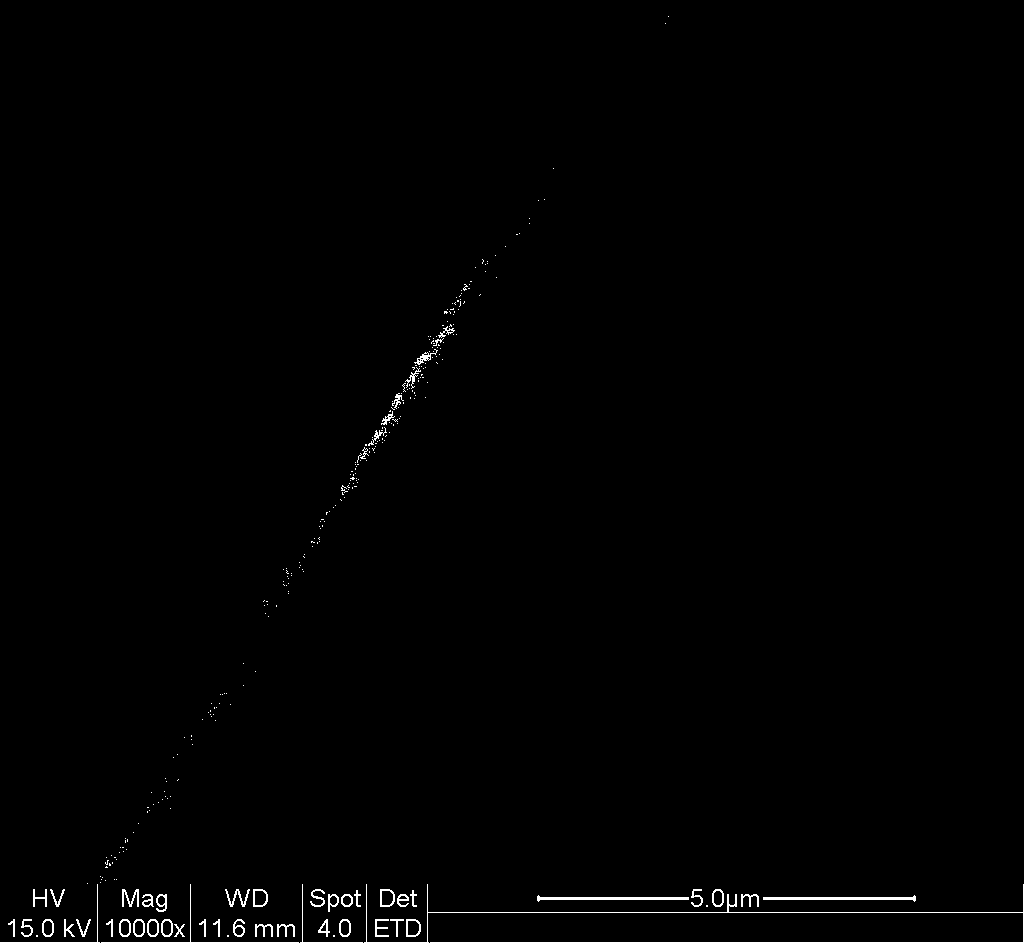

[0027] Weigh 0.1 g of montmorillonite, ultrasonically disperse in 26.9 mL of chloroform until uniformly dispersed, then add 2 g of PMMA, and stir at room temperature until a clear and transparent solution is obtained. Electrospinning is carried out through a multi-nozzle electrospinning device. The spinning voltage is 15kV, the spinning distance is 15cm, and the advancing speed is 0.5ml / h. The receiving device is a winding and unwinding device, and the surface is covered with PET spunbonded nonwoven base fabric. , the obtained porous composite nanofibers (transmission electron microscope picture as Figure 5 shown) is deposited on the surface of PET spunbonded nonwoven base fabric, and compounded by subsequent hot rolling device.

Embodiment 2

[0029] Weigh 0.2 g of montmorillonite, ultrasonically disperse it in 26.9 mL of chloroform until it is evenly dispersed, then add 2 g of PMMA, and stir at room temperature until it becomes a clear and transparent solution. Electrospinning is carried out through a multi-nozzle electrospinning device. The spinning voltage is 20kV, the spinning distance is 15cm, and the advancing speed is 0.8ml / h. The receiving device is a winding and unwinding device, and the surface is covered with PET spunbonded nonwoven base fabric. , the obtained porous composite nanofibers are deposited on the surface of the PET spunbonded nonwoven base fabric, and are composited by a subsequent hot rolling device.

Embodiment 3

[0031] Weigh 0.3 g of montmorillonite, ultrasonically disperse in 26.9 mL of chloroform until uniformly dispersed, then add 2 g of PMMA, and stir at room temperature until a clear and transparent solution is obtained. Electrospinning is carried out through a multi-nozzle electrospinning device. The spinning voltage is 15kV, the spinning distance is 15cm, and the advancing speed is 1.0ml / h. The receiving device is a winding and unwinding device, and the surface is covered with PET spunbonded nonwoven base fabric , the obtained porous composite nanofibers are deposited on the surface of the PET spunbonded nonwoven base fabric, and are composited by a subsequent hot rolling device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com