A kind of pulverized coal fiber separator

A fiber separation and pulverized coal technology, which is applied in the direction of solid separation, classification, and separation of solids from solids with airflow, can solve the problems of increasing the labor intensity of maintenance workers, affecting the normal operation of the system, and affecting the flux of pulverized coal. Achieve the effect of simple structure, prevent bridging, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

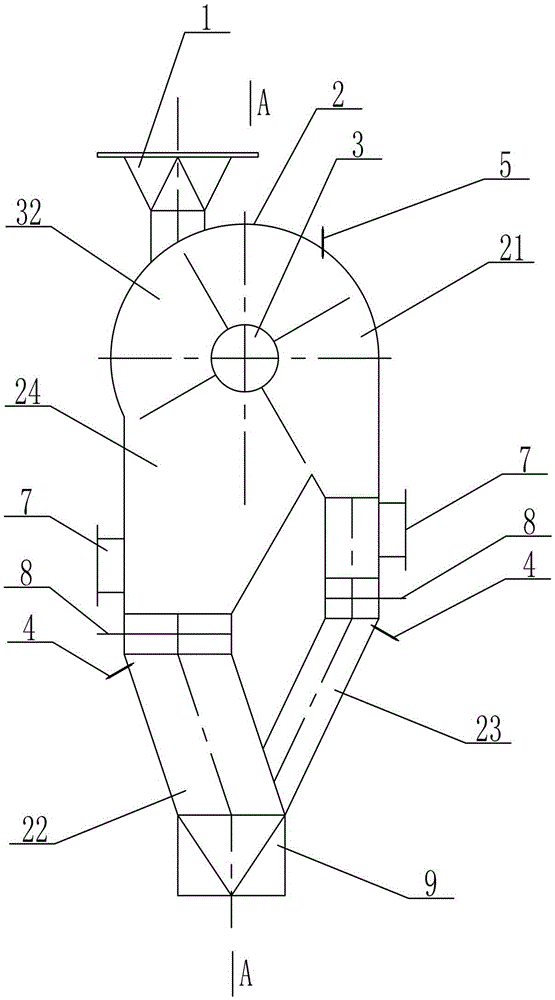

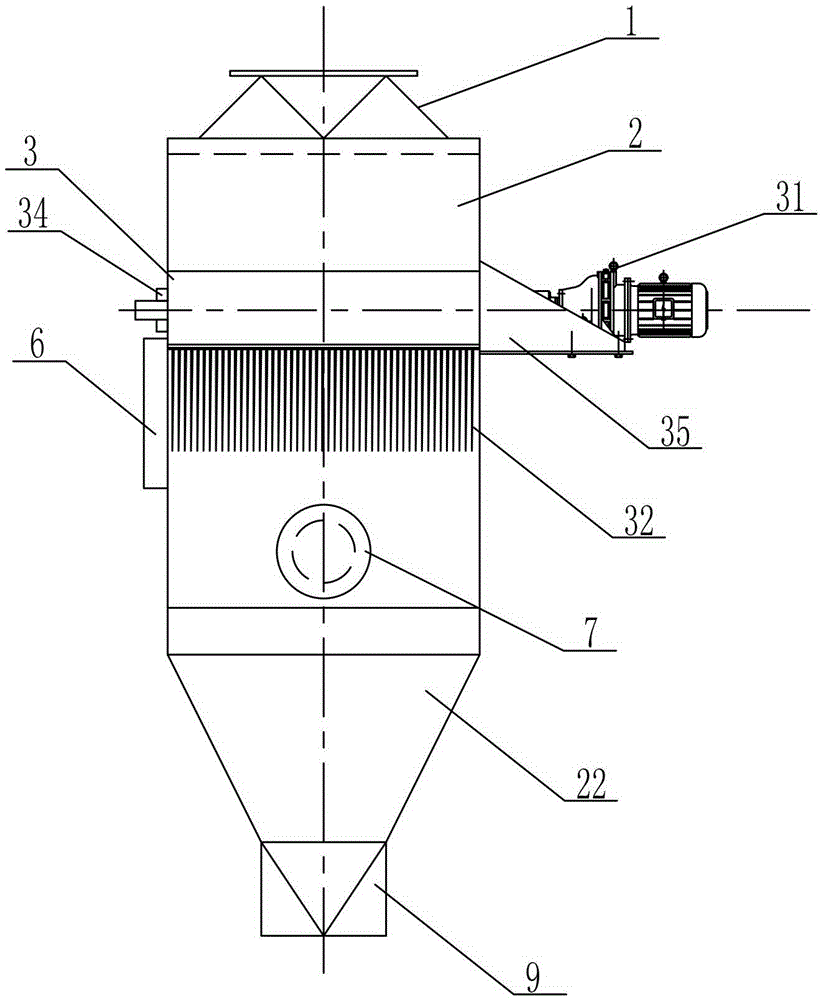

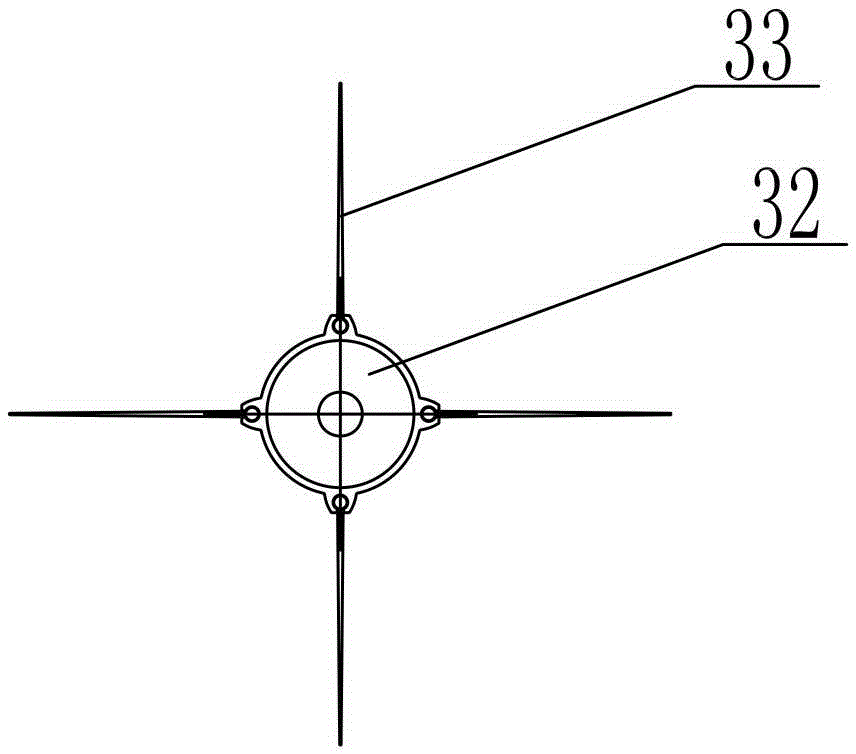

[0017] See attached figure 1 ~attached figure 2 , the present invention consists of a comb filter mechanism 3 arranged on the shell 2, the top of the shell 2 is provided with a feed port 1, and the bottom of the shell 2 is provided with a discharge port 9; the shell 2 is composed of a horizontal cylinder 21 The connected pulverized coal pipe 22 and the fiber pipe 23 are formed. The pulverized coal pipe 22 and the fiber pipe 23 are connected with the cylinder body 21 by the inclined cone 24 of the bifurcated structure. The discharge port 9 at the bottom of the shell 2 is connected with the pulverized coal pipe 22 and The fiber tube 23 is connected, and the feed port 1 at the top of the shell 2 is arranged on the cylinder 21; the pulverized coal tube 22 and the upper part of the fiber tube 23 are provided with a filter screen 8 with a drawer structure, and the filter screen 8 is connected to the pulverized coal tube 22. It is slidingly connected with the fiber tube 23; the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com