Preparation method of soluble Mg2Si-radical high-strength light-weight balls for oil-gas fracturing

A soluble, oil-pneumatic technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., to achieve the effect of good solubility, light weight and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

[0027] A kind of soluble Mg for oil and gas fracturing 2 The preparation method of Si-based high-strength lightweight ball is characterized in that the method comprises the following steps:

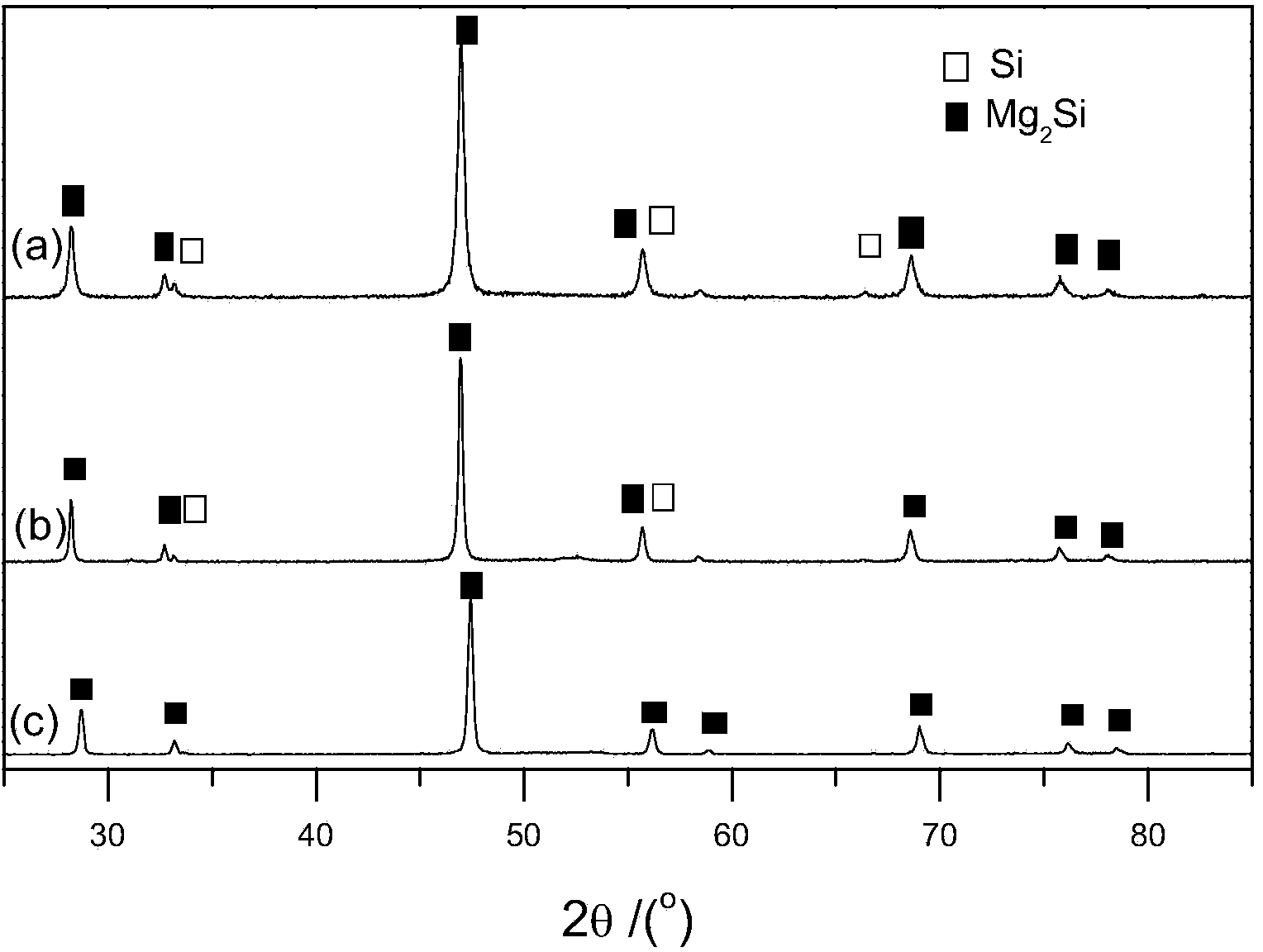

[0028] Step 1, prepare Mg 2 Si-based nano-bulk

[0029] The raw materials are Mg powder and Si powder, and the raw material powder is obtained at a mass ratio of 1.7311.904:1, and the raw material powder is added to a process control agent to obtain a mixture, and the mass ratio of the process control agent to the raw material powder is 6- 10:1;

[0030] Put the above mixture into a stainless steel vacuum ball mill tank, and ball mill under the protection of high-purity Ar (99.999%), and the ball milling time is 7h-25h.

[0031] The ball-milled powder is transferred into a tungsten carbide (WC) mold, and put into a hot-press furnace for vacuum hot-pressing. The holding time is 40-120min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com