Steel Surface Texturization Assisted Friction Stir Welding Method for Aluminum-Steel Dissimilar Material Lap Joints

A technology of dissimilar materials and auxiliary stirring, applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve problems such as low connection strength, embrittlement of connection joints, failure of joints, etc., and achieve reliable strength and smooth seams The shape is beautiful and the effect of automation is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

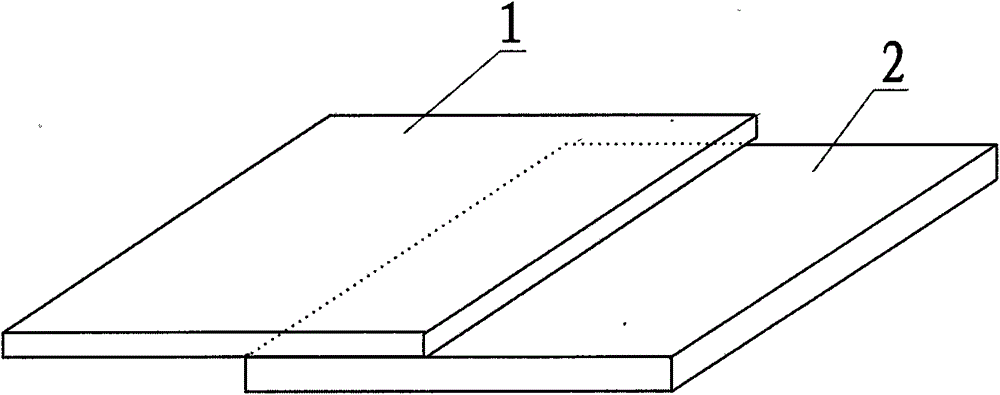

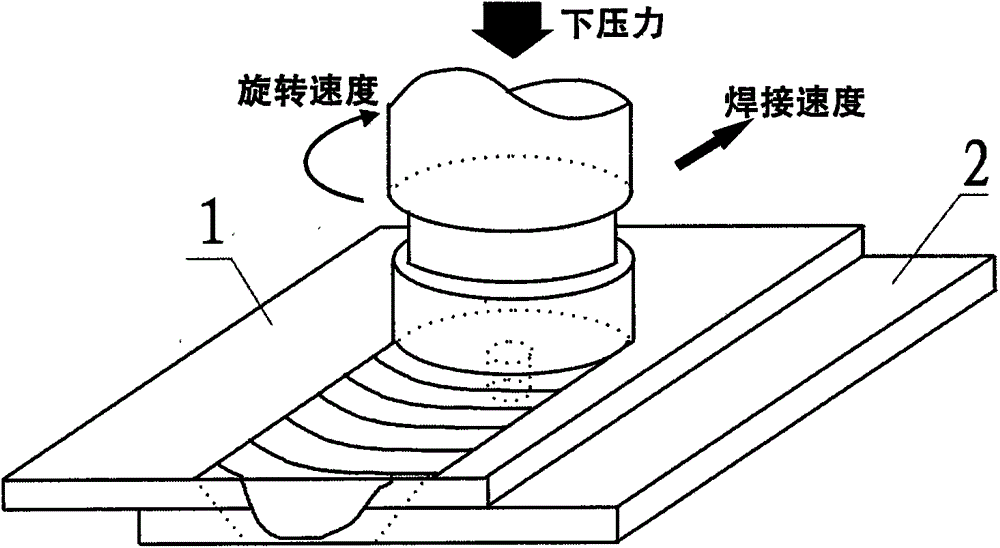

[0019] Such as Figure 1 ~ Figure 3 As shown, this implementation mode is realized through the following steps:

[0020] Step 1. Clean the contact surface of the aluminum plate 1 and the steel plate 2 to be welded and the surrounding 20mm range, and remove oxides on the surface of the test piece, using an electric wire brush or emery cloth, etc.

[0021] Step 2. Use an organic solvent or cleaning agent to wipe the surfaces of the mechanically treated aluminum plate 1 and steel plate 2 to remove oil and metal dust and other impurities. The organic solvent is alcohol or acetone;

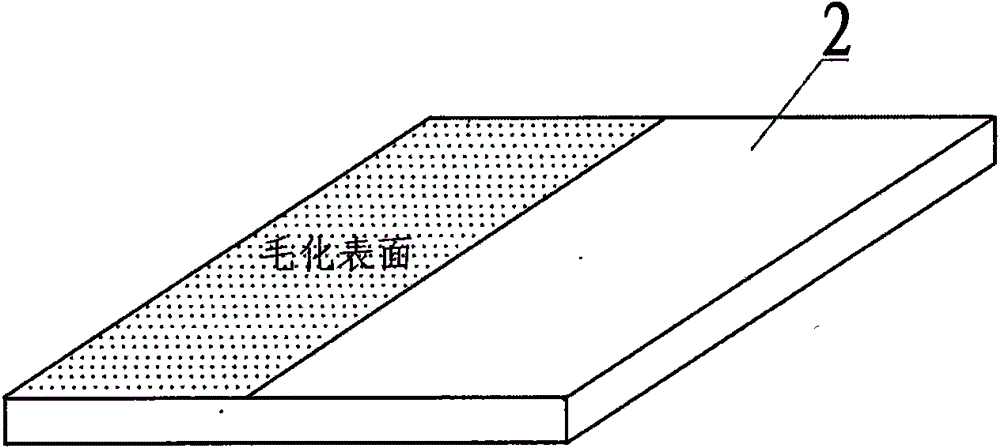

[0022] Step 3. Determine the overlapping area of the joint between the aluminum plate 1 and the steel plate 2, and reach a certain roughness on the part of the steel plate 2 that overlaps with the aluminum plate 1 by roughening, so that the contact surface of the steel plate is evenly distributed with small bumps structure;

[0023] Step 4. The aluminum plate 1 and the steel plate 2 are formed into...

Embodiment 2

[0025] This implementation mode is realized through the following steps:

[0026] Step 1. Clean the contact surface of the aluminum plate and the steel plate to be welded and the surrounding 30mm range, and remove the oxide on the surface of the test piece, using electric wire brush or emery cloth, etc.

[0027] Step 2. Use an organic solvent or cleaning agent to wipe the surface of the mechanically treated aluminum plate and steel plate to remove oil and metal dust and other impurities. The organic solvent is alcohol or acetone, etc.;

[0028] Step 3. Determine the overlapping area of the joint between the aluminum plate and the steel plate, and reach a certain roughness on the part of the steel plate that overlaps the aluminum plate through roughening, so that the contact surface of the steel plate is evenly distributed with fine convex-concave structures;

[0029] Step 4. The aluminum plate and the steel plate are formed into a lap joint with the aluminum plate on the top...

Embodiment 3

[0031] combine figure 2 This embodiment will be described. The texturing methods in this embodiment include laser texturing, electron beam texturing, electric spark texturing and mechanical texturing. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com