Method for machining forge piece of large-scale single-flange anti-explosion motor main shaft of all-fiber texture

An explosion-proof motor and processing method technology, applied in the direction of metal processing equipment, etc., can solve the problems of poor impact resistance, easy vibration, and easy deformation of the flange at the root of the flange, so as to improve product quality and economic benefits, and avoid internal Microcracks, the effect of improving the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0036] Processing method of forging large single flange explosion-proof motor spindle with full fiber structure (drawing number: Y13T156.1)

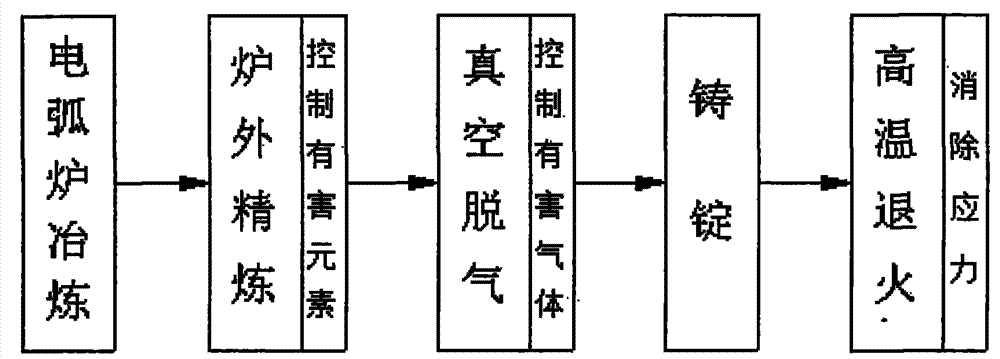

[0037] Step a, raw material quality control, such as figure 1 As shown, steel ingots smelted in electric arc furnace + refined outside the furnace + vacuum degassed are used as raw materials, and the material is 45A, which conforms to Q / HWG-QW07010-2000 and fully meets the JB / T1271-2002I Class I standard. Harmful elements in the chemical composition are controlled as follows: S≤0.025, P≤0.025, Cu≤0.20, H≤2pp pm, 0≤35pp pm, N≤65pp pm;

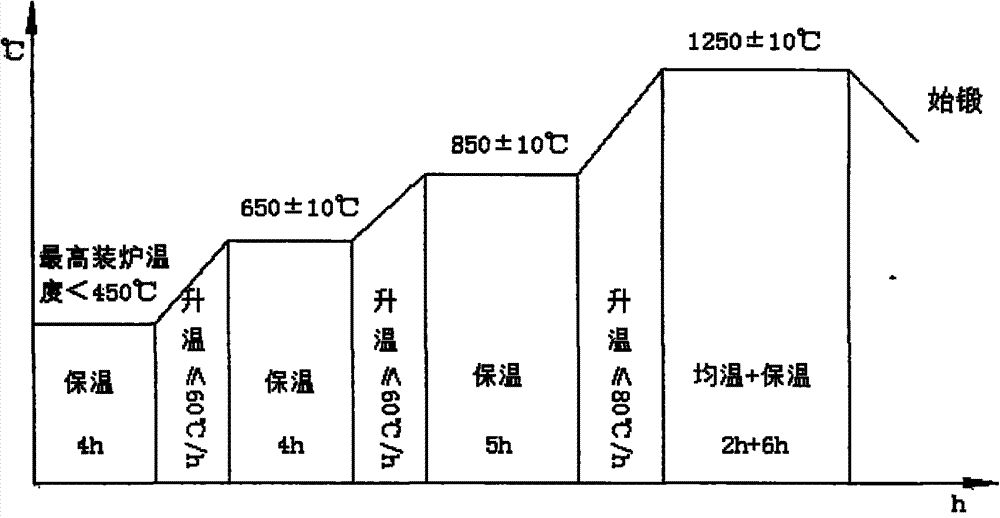

[0038] Step b, such as figure 2 As shown, the steel ingot is heated in a three-stage heating method. The specific heating process is as follows: the steel ingot is placed in a heating furnace with a temperature lower than 450 °C for 4 hours, and then the temperature is rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com