A workpiece, its preparation method, and an electronic device containing the workpiece

A technology for workpieces and electronic components, applied in electrical equipment shells/cabinets/drawers, chemical instruments and methods, electrical components, etc., can solve problems such as surface cracking and high internal stress of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take a layer of magnetically conductive stainless steel, each layer with a thickness of 0.5mm, and a layer of polycarbonate with a thickness of 0.8mm.

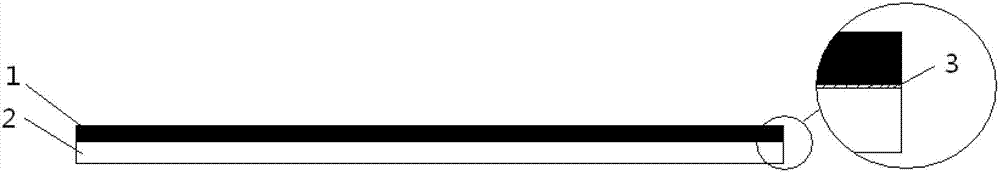

[0057] Combine magnetic stainless steel and polycarbonate according to figure 1 The sequence shown is placed in a jig, and the magnetically permeable stainless steel and polycarbonate are fixed, pressed and leveled using the jig. in, figure 1 Including surface layer 1, support layer 2 and connecting layer 3.

[0058] Put the jig on the electromagnetic wave furnace to heat the steel sheet to 300° C. within 0.5 to 1 second. The connection layer formed between magnetically conductive stainless steel and polycarbonate melts instantly to release internal stress.

[0059] Remove the jig for proper cooling and remove the parts to complete the shape correction.

Embodiment 2

[0061] Take a layer of magnetically conductive stainless steel, each layer is 0.5mm thick, and a layer of polypropylene, each layer is 0.8mm thick.

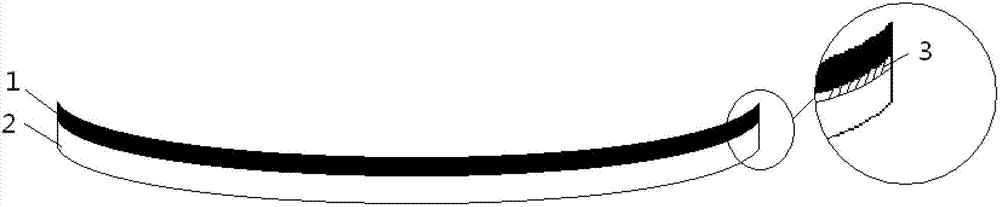

[0062] Combine magnetic stainless steel and polycarbonate according to figure 2 The sequence shown is placed in a jig, and the magnetically permeable stainless steel and polycarbonate are fixed, pressed and leveled using the jig. in, figure 2 Including surface layer 1, support layer 2 and connecting layer 3.

[0063] Put the jig on the electromagnetic wave furnace to heat the steel sheet to 300° C. within 0.5 to 1 second. The connection layer formed between magnetically conductive stainless steel and polycarbonate melts instantly to release internal stress.

[0064] Remove the jig for proper cooling and remove the parts to complete the shape correction.

Embodiment 3

[0066] Take a layer of magnetically conductive stainless steel, each layer thickness is 0.5mm, and a layer of ABS, each layer thickness is 0.8mm.

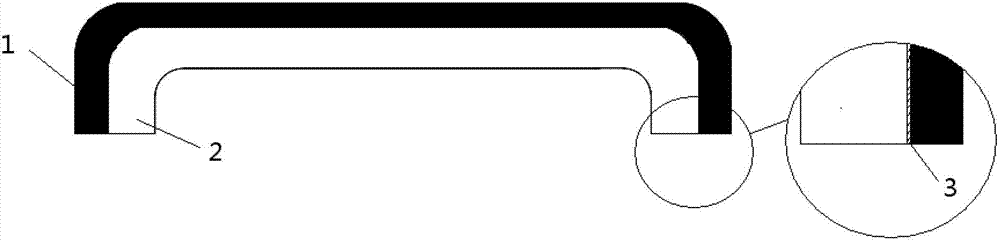

[0067] Combine magnetic stainless steel and polycarbonate according to image 3 The sequence shown is placed in a jig, and the magnetically permeable stainless steel and polycarbonate are fixed, pressed and leveled using the jig. in, image 3 Including surface layer 1, support layer 2 and connecting layer 3.

[0068] Put the jig on the electromagnetic wave furnace to heat the steel sheet to 300° C. within 0.5 to 1 second. The connection layer formed between magnetically conductive stainless steel and polycarbonate melts instantly to release internal stress.

[0069] Remove the jig for proper cooling and remove the parts to complete the shape correction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com