A continuous buoy composite material floating structure system

A composite material, floating structure technology, applied in the direction of floating buildings, etc., can solve the problems of shortening the construction time of the floating structure, complicated on-site installation, low bearing capacity, etc., and achieves the effects of simple construction, fast erection and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

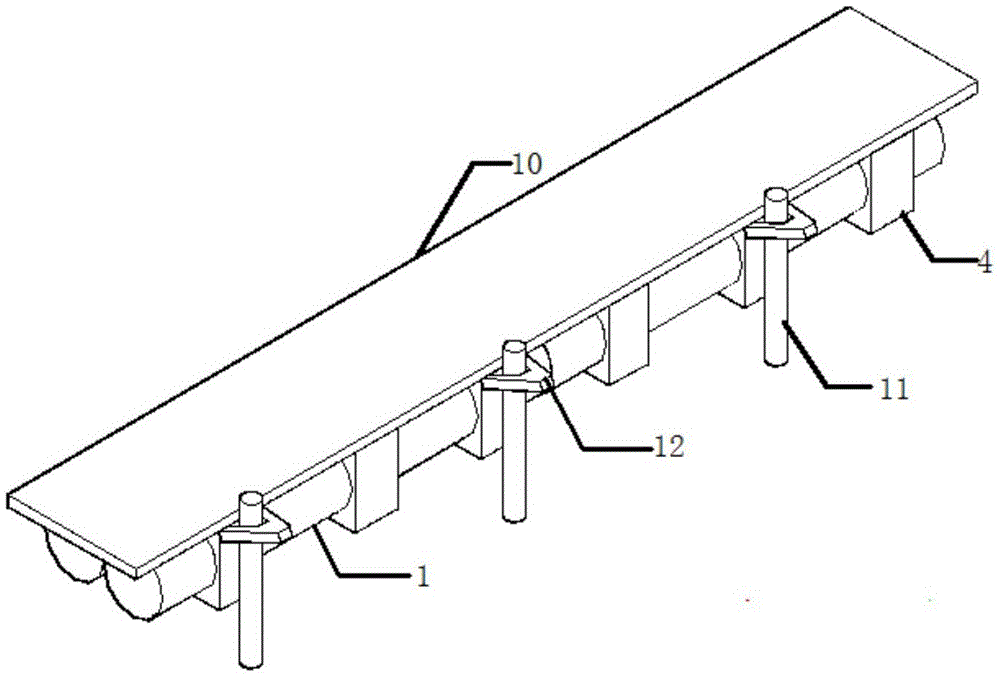

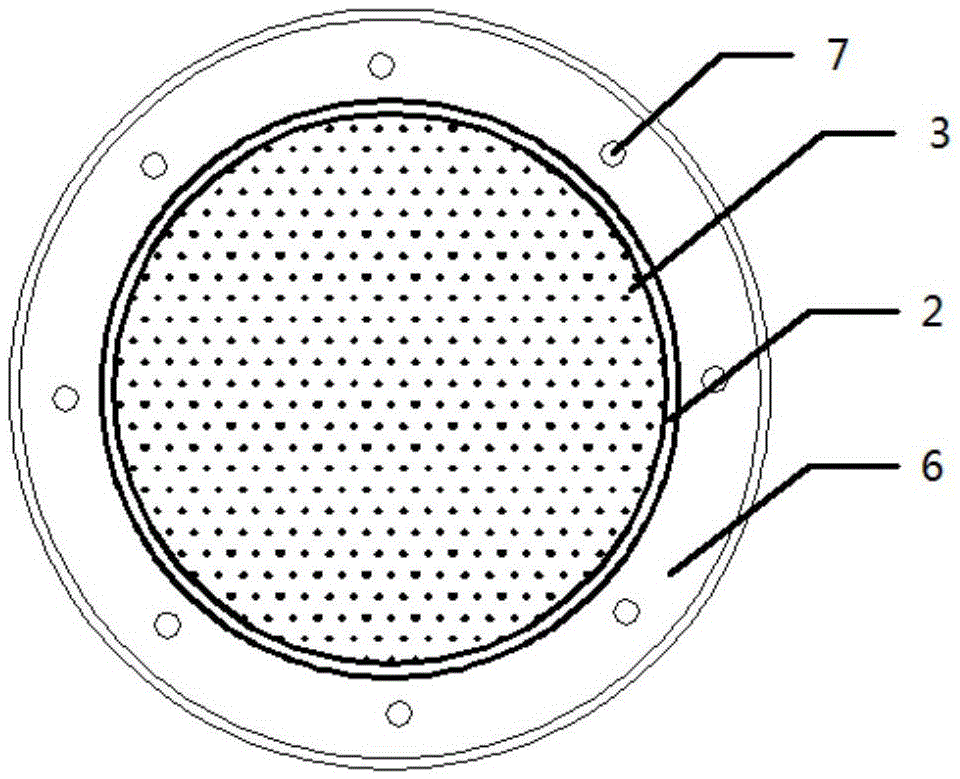

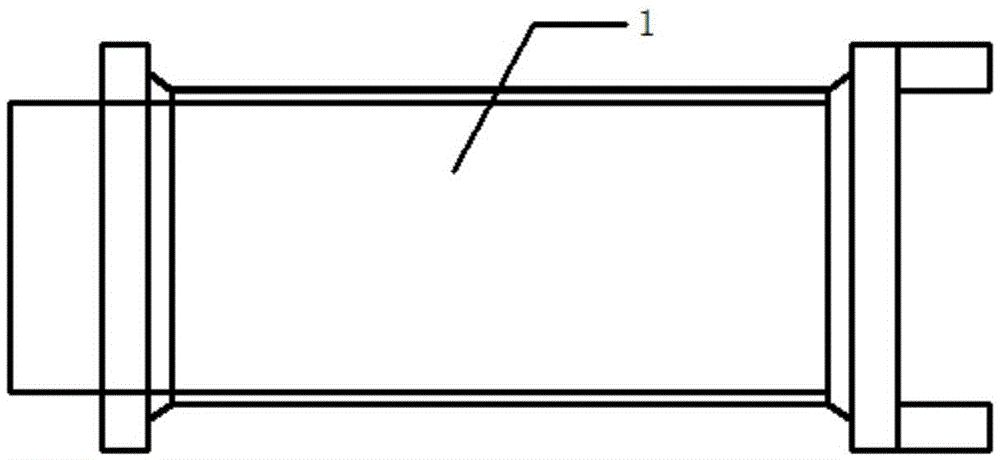

[0033] The continuous buoy composite floating structure of the present invention, such as Figure 1-7 shown. Composite circular buoy unit 1 with equal cross-section is made of basalt fiber cloth and vinyl ester resin through winding process to form a composite tube, and the filler 3 in the composite shell 2 is PU foam. The connections between adjacent buoy units are connected by socket flanges 6 and bolts 7 . The double buoys are placed side by side, and the double buoy connection unit is used to fix the double buoys. The buoy connection unit 4 is a sandwich panel shell structure made of vacuum introduction technology. The panel shell is made of glass fiber and unsaturated polyester resin. The sandwich material 5 Use polyvinyl chloride foam. The bridge deck structure system 10 includes a frame 14 of composite material, on which a sandwich panel shell 13 of composite material is laid, and the structure of the sandwich panel is the same as that of the plywood connection unit. ...

Embodiment 2

[0035] The continuous buoy composite floating structure of the present invention, such as Figure 1-5 and 8-9. The equal-section circular buoy unit 1 is prepared by winding process of glass fiber and unsaturated polyester resin, and the filling body 3 in the composite material shell 2 is polystyrene foam; the connection between adjacent buoy units adopts socket flanges 6 and Bolt 7 connection; the double buoys are placed side by side, and the double buoy connection unit 4 is used to fix the double buoys. The buoy connection unit adopts the sandwich panel shell structure made of vacuum introduction process, and the panel shell is made of glass fiber and unsaturated polyester resin. The sandwich material 5 uses polyurethane foam; the equal-section circular buoy unit 1 of the auxiliary trestle is connected with the buoy connection unit 4; Unsaturated polyester resin and paulownia wood are made by pultrusion process. The pile holding device 12 is arranged on the outside of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com