Method for preparing industrial grade monoammonium phosphate by using raffinate acid through twice neutralizational process

A technology of monoammonium phosphate and raffinate acid, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of high impurity content, low nitrogen content level, high viscosity of slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

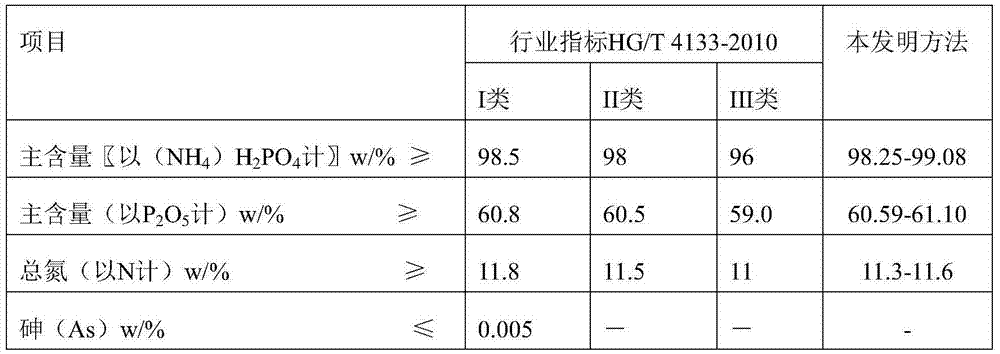

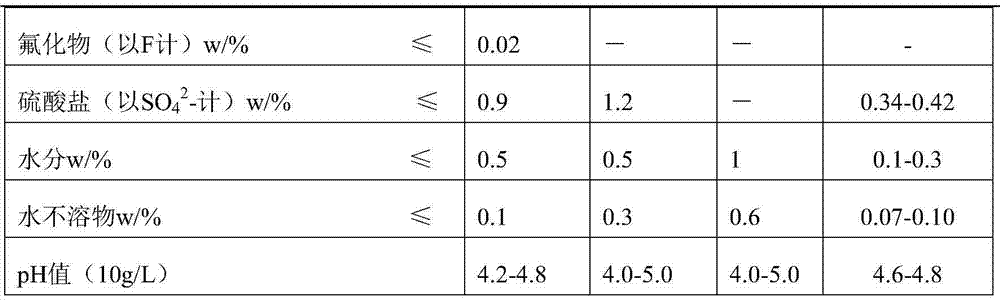

Embodiment 1

[0022] The raffinate (P 2 o 5 Content by weight 45.6%) mixed with water at a mass ratio of 1:1.5, the diluted raffinate enters the first reactor A, and ammonia is passed through for the first neutralization reaction, the reaction temperature is 70 ° C, to The pH of the material is 3.5, and it is fully matured for 3 hours; after the slurry is filtered, the obtained filtrate enters the second reactor B and passes through ammonia for the second neutralization reaction. The reaction temperature is 55 ° C, and the pH of the slurry is At 4.5, mature again for 3 hours; the slurry is filtered and concentrated, and the concentration ratio is controlled until the relative density of the filtrate reaches 1.37, then cooled to 40°C for crystallization, the crystallization time is 20 minutes, and then the filtrate is centrifuged and dried to obtain industrial grade phosphoric acid monoammonium. After the determination of the main content of the product (in P 2 o 5 Calculated) is 61.08%,...

Embodiment 2

[0024] The raffinate (P 2 o 5 The content is 45.6% by weight) mixed with water at a mass ratio of 1:1, the diluted raffinate enters the first reactor A, and ammonia is passed through to carry out the first neutralization reaction, the reaction temperature is 65 ° C, to The pH of the material is 3.5, and it is fully matured for 3 hours; after the slurry is filtered, the resulting filtrate enters the second reactor B and passes through ammonia for the second neutralization reaction until the pH of the slurry is 4.5, and the reaction temperature is 55°C, aging again, the time is 2 hours; the slurry is filtered and concentrated, the concentration ratio is controlled until the relative density of the filtrate reaches 1.37, then cooled to 40°C for crystallization, the crystallization time is 20 minutes, and then the filtrate is centrifuged and dried to obtain industrial grade phosphoric acid monoammonium. After the determination of the main content of the product (in P 2 o 5 Cal...

Embodiment 3

[0026] The raffinate (P 2 o 5 Content by weight 45.6%) mixed with water at a mass ratio of 1:1.5, the diluted raffinate enters the first reactor A, and ammonia is passed through for the first neutralization reaction, the reaction temperature is 70 ° C, to The pH of the material is 3.5, and it is fully matured for 2 hours; after the slurry is filtered, the resulting filtrate enters the second reactor B and passes through ammonia for the second neutralization reaction until the pH of the slurry is 4.5, and the reaction temperature is 50°C, aging again, the time is 3 hours; the slurry is filtered and concentrated, the concentration ratio is controlled until the relative density of the filtrate reaches 1.37, then cooled to 40°C for crystallization, the crystallization time is 20 minutes, and then the filtrate is centrifuged and dried to obtain industrial grade phosphoric acid monoammonium. After the determination of the main content of the product (in P 2 o 5 Calculated) is 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com