Diamond synthesis rod purification process

A diamond and synthetic rod technology is applied in the field of diamond synthetic rod purification technology, which can solve the problems of air pollution, long process, and inability to disperse, and achieves the effects of reducing pollution, improving economic efficiency, and accelerating electrolysis speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

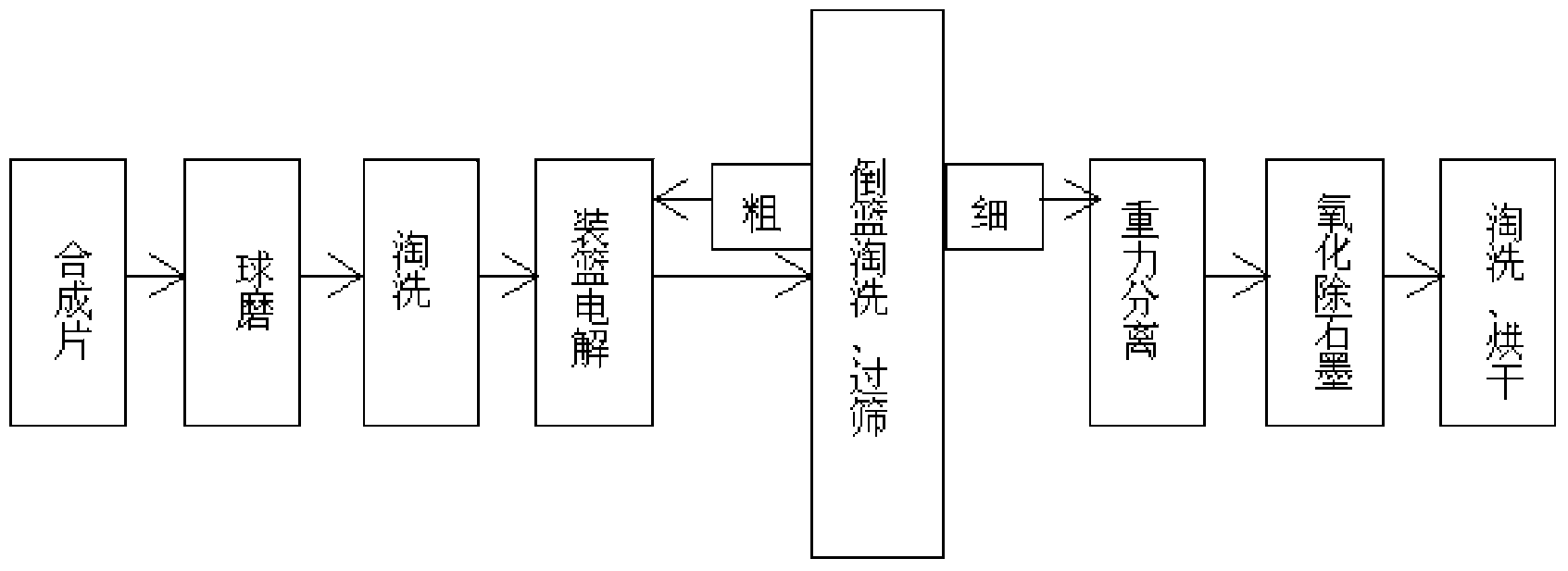

[0011] Referring to the accompanying drawings, a purification process of diamond synthetic rods, diamond synthetic sheets are ball milled, elutriated, basket electrolyzed, inverted basket elutriated, sieved, gravity separated, oxidized to remove graphite, elutriated, and dried. The oxidizing agent for graphite removal is potassium permanganate and concentrated sulfuric acid to generate manganese heptoxide. During ball milling, the ball-material ratio is 3:1, and the rotating speed of the grinding cylinder is 40r / min-100r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com