A kind of preparation method of high specific surface area multi-stage pore diameter activated carbon

A high specific surface area, activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of small specific surface area and single pore size of activated carbon, achieve long preparation time, fast charge and discharge speed, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

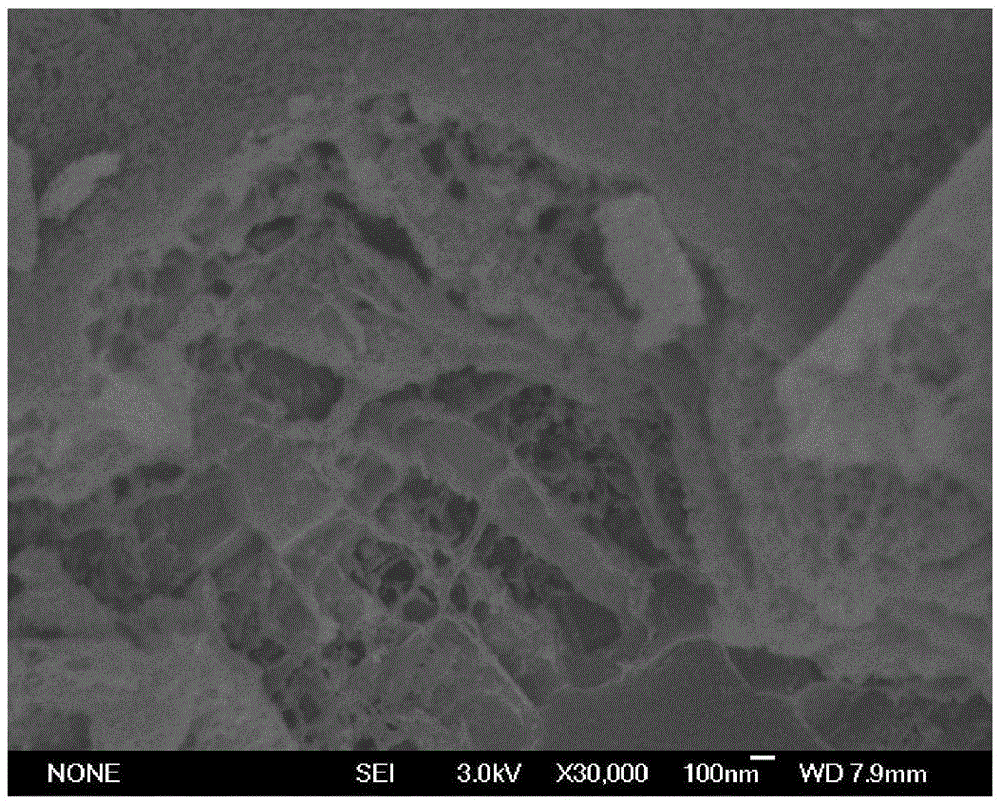

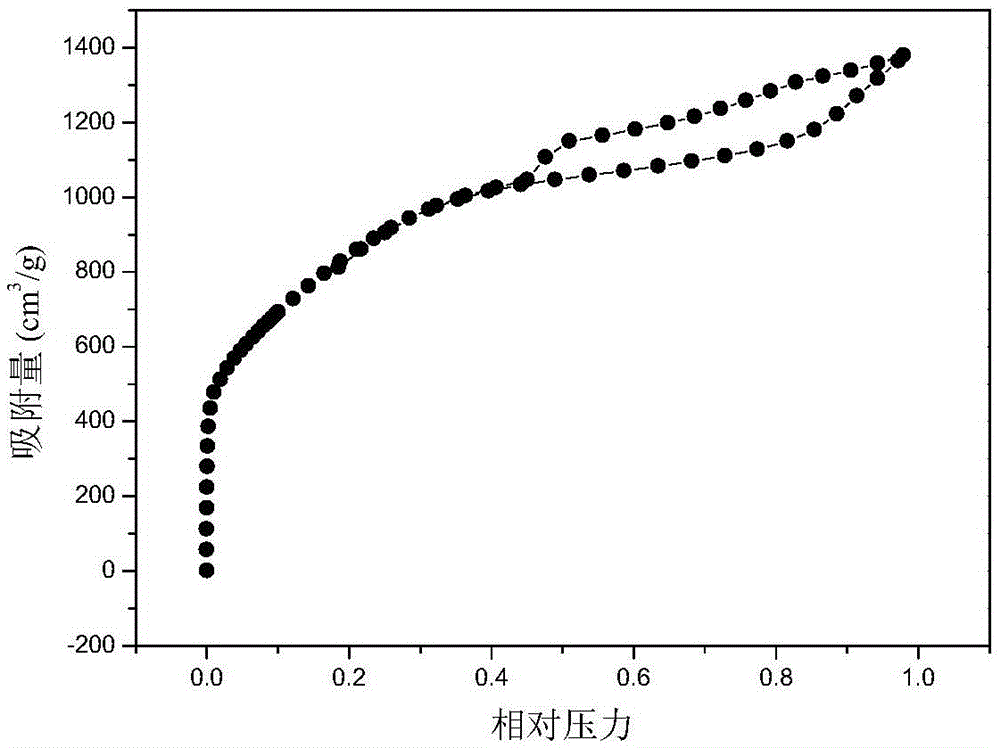

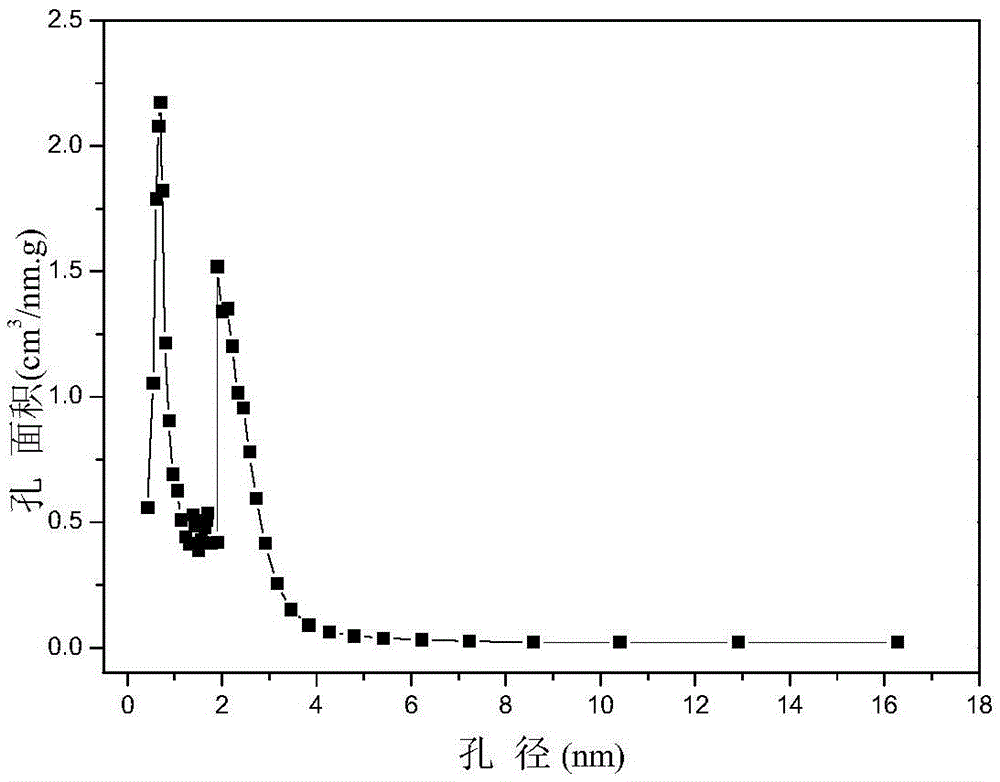

[0036] A preparation method of high specific surface multi-stage pore diameter activated carbon, the steps are as follows:

[0037] 1. Pretreatment of Enteromorpha: After the Enteromorpha is dried, pulverize and pass through a 40-mesh sieve to obtain Enteromorpha powder.

[0038] 2. Put the Enteromorpha powder into a porcelain crucible with a cover, place the crucible in a microwave digestion furnace to heat, control the heating rate at 20°C / min, and control the microwave power at 700W. After heating, the temperature of the material is kept at 450°C and heated for 10 minutes. After being released from the oven, enteromorpha carbonized material is obtained;

[0039] 3. Take Enteromorpha carbonized material and add it to the mortar, and then add sodium metaaluminate. The mass ratio of carbonized material to sodium metaaluminate is 1:3. After grinding for 20 minutes, according to the mass ratio of Enteromorpha carbonized material to 1: Add deionized water at a ratio of 1, stir e...

Embodiment 2

[0044] 1. Pretreatment of Enteromorpha: After the Enteromorpha is dried, pulverize and pass through a 40-mesh sieve to obtain Enteromorpha powder.

[0045] 2. Put the Enteromorpha powder into a porcelain crucible with a cover, and place the crucible in a microwave digestion furnace to heat. The heating rate is controlled at 18°C / min, and the microwave power is controlled at 800W. After heating, the temperature of the material is kept at 500°C, and heated for 15 minutes. After being released from the oven, enteromorpha carbonized material is obtained;

[0046] 3. Take Enteromorpha carbonized material and add it to the mortar, and then add sodium metaaluminate. The mass ratio of Enteromorpha carbonized material to sodium metaaluminate is 1:1. After grinding for 20 minutes, press the mass ratio of Enteromorpha carbonized material Add deionized water at a ratio of 0.5:1, stir evenly, and place the mixture in an oven at 105°C for 2.0 hours. Then the mixture was heated and activate...

Embodiment 3

[0048] 1. Pretreatment of Enteromorpha: After the Enteromorpha is dried, pulverize and pass through a 45-mesh sieve to obtain Enteromorpha powder.

[0049] 2. Put the Enteromorpha powder into a porcelain crucible with a cover, heat the crucible in a microwave digestion furnace, control the heating rate at 20°C / min, and control the microwave power at 900W. After heating, the temperature of the material is kept at 550°C and heated for 5 minutes After being released from the oven, enteromorpha carbonized material is obtained;

[0050] 3. Take Enteromorpha carbonized material and add it to the mortar, and then add sodium metaaluminate. The mass ratio of Enteromorpha carbonized material to sodium metaaluminate is 1:2. After grinding for 25 minutes, according to the mass ratio of Enteromorpha carbonized material Add deionized water at a ratio of 0.8:1, stir evenly, and place the mixture in an oven at 100°C for 3.0 hours. Then the mixture was heated and activated in a tubular heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com