Draining pump

A technology for drainage pumps and water pump casings, applied to pumps, pump devices, pump components, etc., can solve the problems of reduced blade efficiency and low workmanship efficiency, and achieve the effects of ensuring long life, suppressing noise, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

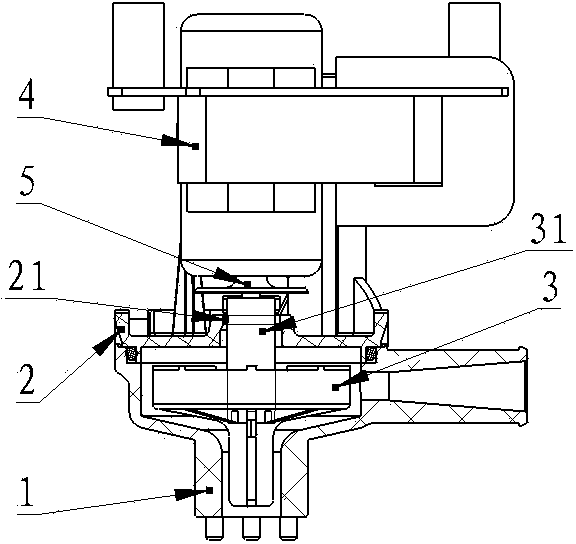

[0039] like figure 1 As shown, a drainage pump installed in an air conditioner includes a water pump casing (1), a motor casing (2), an impeller (3) and a motor (4) that drives the rotation of the impeller (3) to realize the drainage function , water retaining piece (5), the middle of the impeller (3) is provided with a wheel shaft (31) connected to the motor shaft (6) of the motor (4), and the upper part of the wheel shaft (31) runs through the motor casing (2 ) of the hollow portion (21). The upper part of the motor housing is provided with a water retaining piece (5), and the gap value A between the water retaining plate (5) and the end of the motor housing (2) ranges from 1 to 7mm (such as Figure 8 shown).

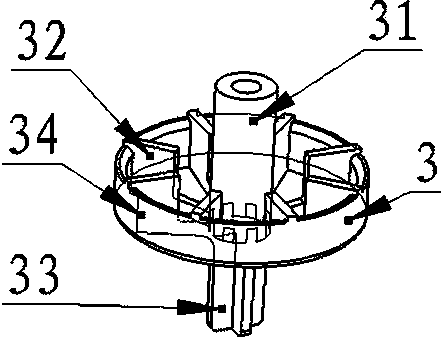

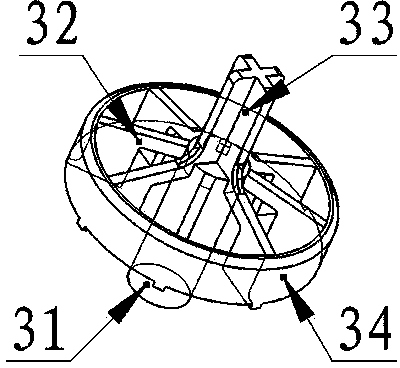

[0040] figure 2 and image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com