Novel drying device and drying method of polyester filaments

A drying device, polyester technology, applied in the direction of drying, drying machine, heating device, etc., to achieve the effect of not easy to lag and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

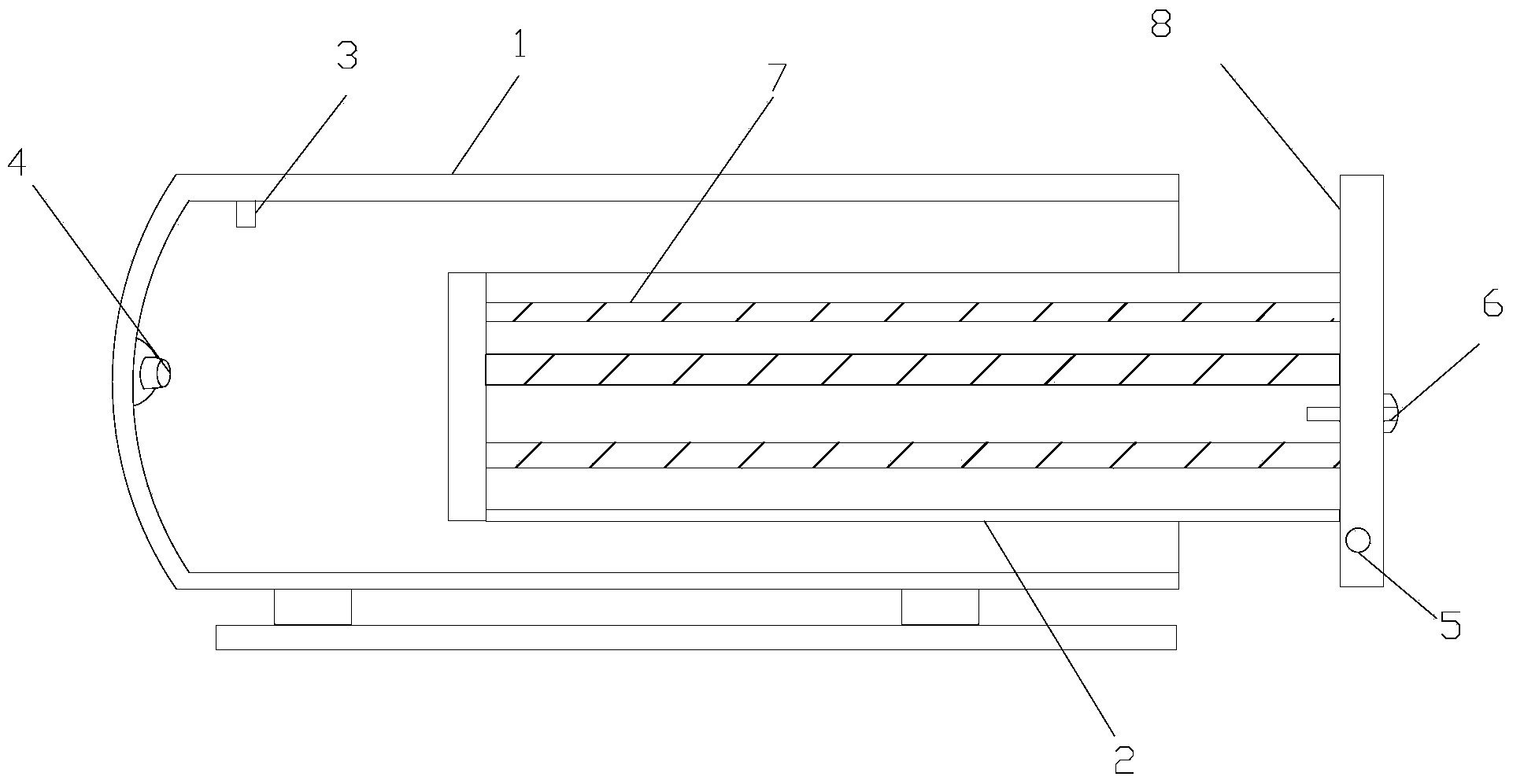

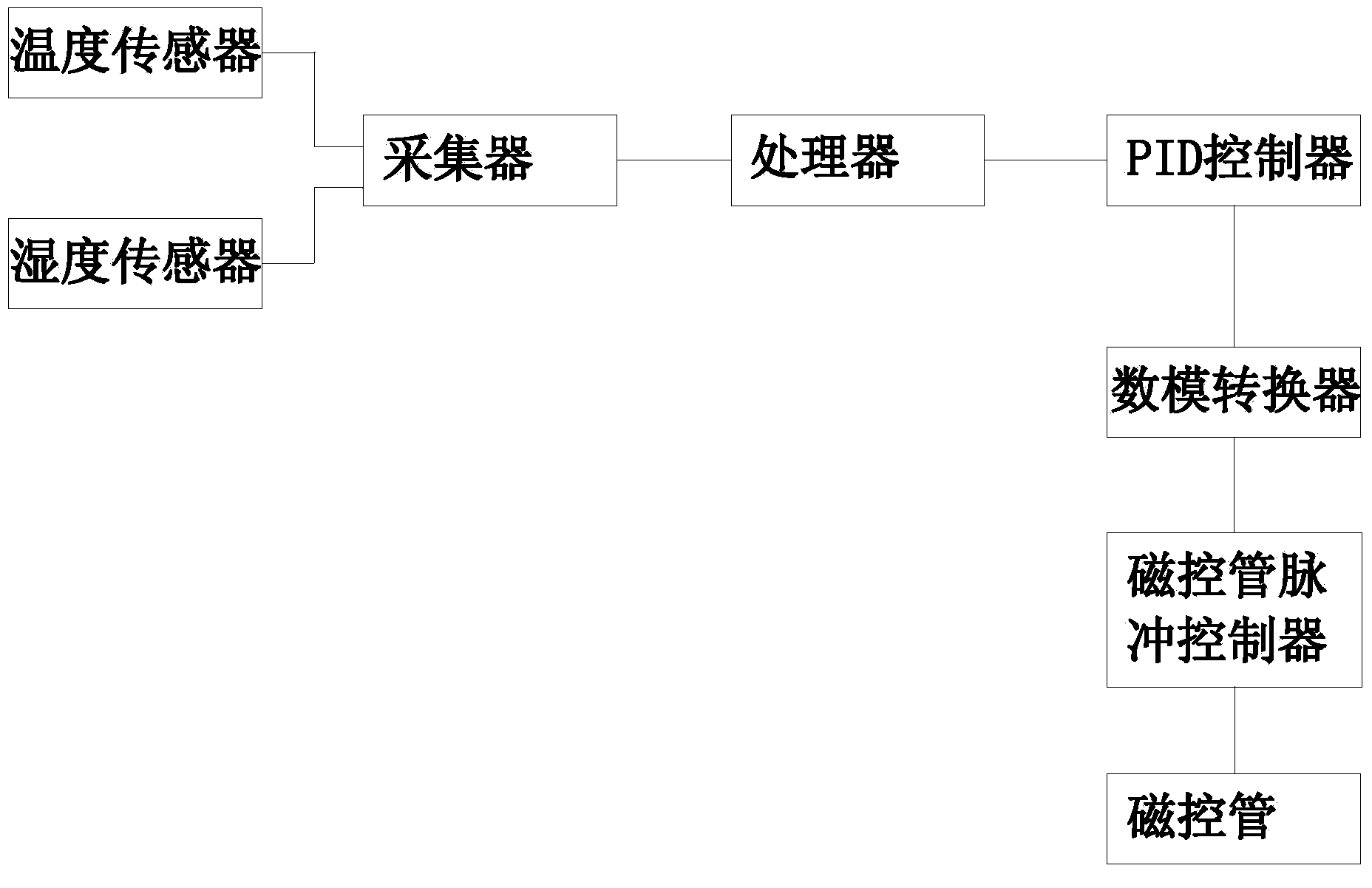

[0016] Such as figure 1 , 2 As shown, the novel drying device for polyester yarn described in this embodiment includes a drying box 1 and a drawer 2 matched with the drying box 1, and a temperature sensor 3 and a magnetron are arranged in the drying box 1. 4. An electromagnetic lock 5 is provided on the side of the panel 8 of the drawer 2, and a humidity sensor 6 is provided on the drawer 2. The temperature sensor 3 and the humidity sensor 6 are connected to a collector, and the collector is connected to a PID through a processor. Controller, PID controller connects described magnetron 4 through digital-to-analog converter, magnetron 4 pulse controllers; Described drawer 2 is provided with upper, middle and lower three-layer pallet 7, and described humidity sensor 6 is installed on On the panel 8 of the drawer 2 and the measuring end of the humidity sensor 6 is located between the pallets 7 . Wherein, the circuit system adopted in this embodiment is disclosed in Chinese pate...

Embodiment 2

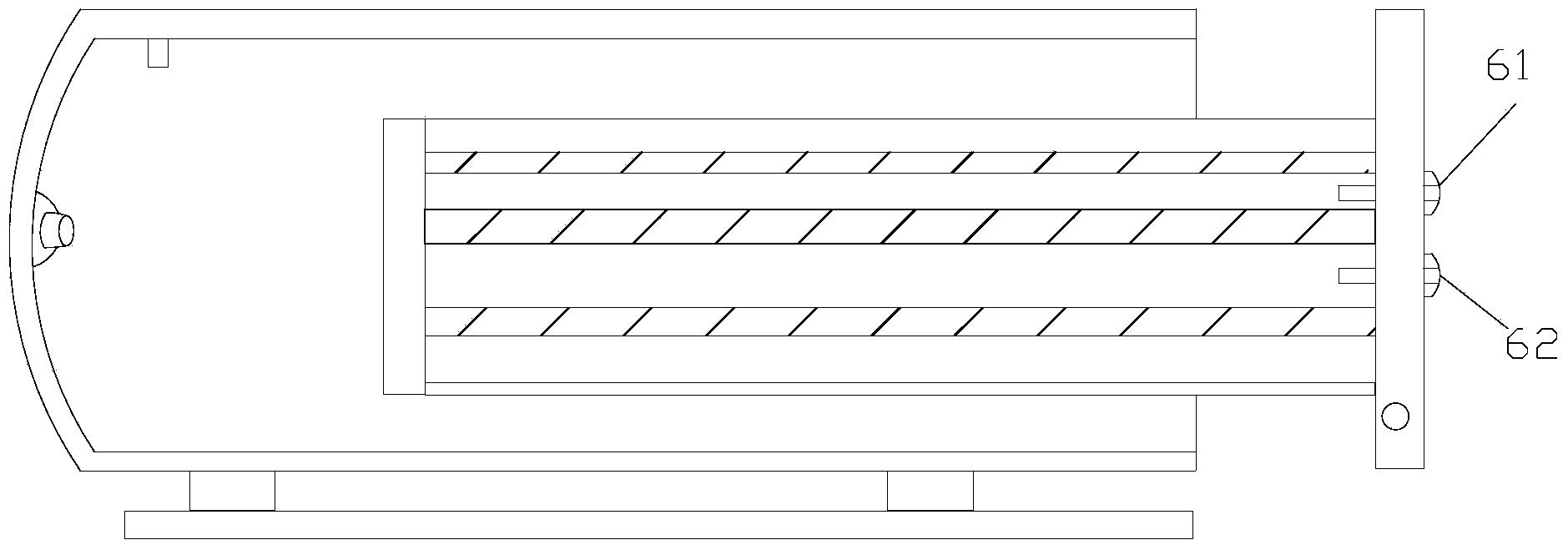

[0020] Such as image 3 , 4 As shown, the new drying device for polyester yarn described in this embodiment is different from Embodiment 1 in that: the humidity sensor 6 is divided into a first humidity sensor 61 and a second humidity sensor 62, and the first humidity The sensor 61 is located between the upper and middle two pallets 7, the second humidity sensor 62 is located between the middle and lower two pallets 7, and the first humidity sensor 61 and the second humidity sensor 62 are connected to each other through an average value circuit. the collector.

[0021] The humidity between the upper and middle two pallets is slightly different from the humidity between the middle and lower two pallets (the upper part is slightly higher than the lower part), and the humidity can be controlled more evenly after taking the average value. The average value circuit is an existing technology, as described in Chinese patent ZL2013203272441, it can be a current average value circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com