Polarization-maintaining flat optical fiber coupling ball microscale sensor based on polarization state detection

A fiber coupling, polarization state technology, applied in instruments, measurement devices, optical devices, etc., can solve problems such as low primary amplification, inability to apply, and increased data volume, to meet industrial needs, improve adaptability, and processing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

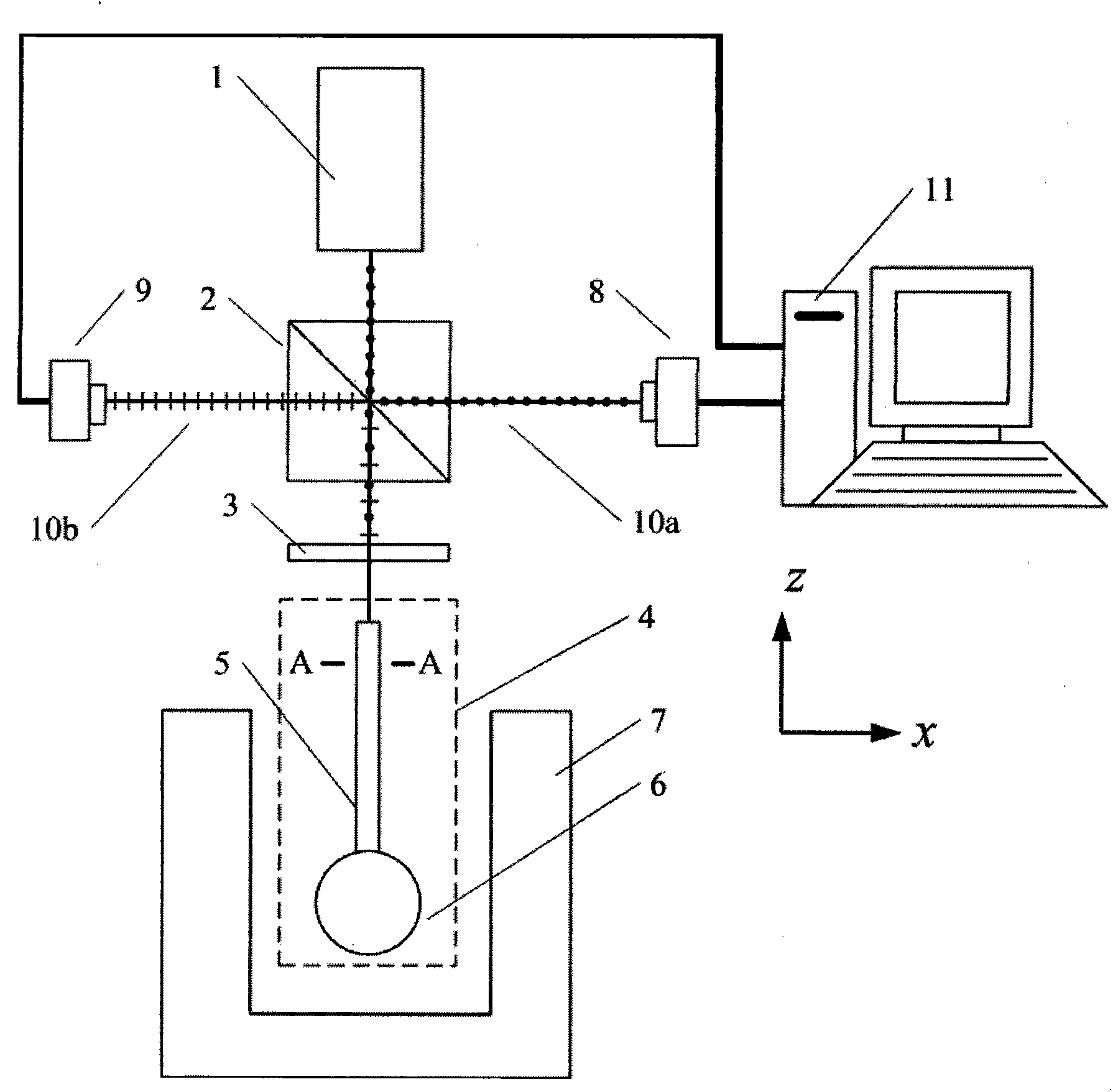

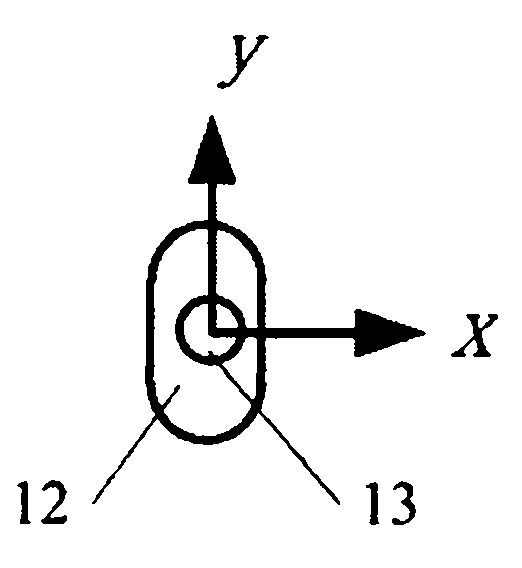

[0023] A polarization-maintaining flat fiber-coupled spherical microscale sensor based on polarization detection, the sensor includes a laser 1, a half-transparent and half-reflective prism 2, Wave plate 3, probe 4, polarization state detection device A8, polarization state detection device B9, computer 11, described probe 4 is made up of optical fiber 5 and coupling ball 6, and described optical fiber 5 is flat-clad polarization-maintaining optical fiber, Optical fiber 5 is made of flat cladding 12 and fiber core 13, and one end of optical fiber 5 is fixedly connected with coupling ball 6, and coupling ball 6 is used as the contact of probe 4; The wave plate 3 and the probe 4 are arranged in sequence, wherein the optical axis of the beam transmitted by the semi-transparent and half-reflective prism 2 of the outgoing light of the laser 1 coincides wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com